When inspecting raw materials for undercarriage parts for excavators & bulldozer, meeting industry benchmarks 1 is crucial for reliable performance. My approach ensures nothing less than consistency and durability.

Adhering to strict quality standards is essential for verifying incoming materials. Ensuring compliance with necessary industry regulations 2 safeguards product integrity, minimizes defects, and bolsters operational efficiency.

Quality control for raw materials 3 ensures continuous supply chain excellence, maintaining high standards throughout manufacturing stages. Innovations in inspection techniques 4 drive efficiency and accuracy.

Do you use a spectrometer to verify the chemical composition of all incoming steel?

Using spectrometry for verifying incoming steel’s chemical composition 5 is highly effective in ensuring material integrity. Implementing this advanced analysis minimizes the risk of alloy discrepancies and enhances product reliability.

Spectrometry helps confirm the alloy composition, delivering precise identification of elements like carbon and manganese. It is crucial for maintaining consistency and meeting regulatory requirements for high-quality manufacturing.

Dive Deeper

Implementing spectrometric analysis ensures comprehensive chemical profiling. This precision enables identification of essential alloy components, safeguarding against composition variances.

Spectrometry Analysis Process

| Element | Significance | Tolerance Levels |

|---|---|---|

| Carbon | Impacts strength and hardness | 0.20% – 0.40% |

| Manganese | Affects ductility and toughness | 1.00% – 1.50% |

| Boron | Enhances hardenability | Up to 0.003% |

Spectrometry uses techniques like Optical Emission Spectrometry (OES) 6 to validate elemental presence. This ensures alignment with industry specifications, reinforcing product quality.

Ensuring Accurate Chemical Composition

Verifying chemical composition is crucial to maintain product standards and durability. Spectrometry acts as a critical checkpoint against material discrepancies, aligning with alloy specifications.

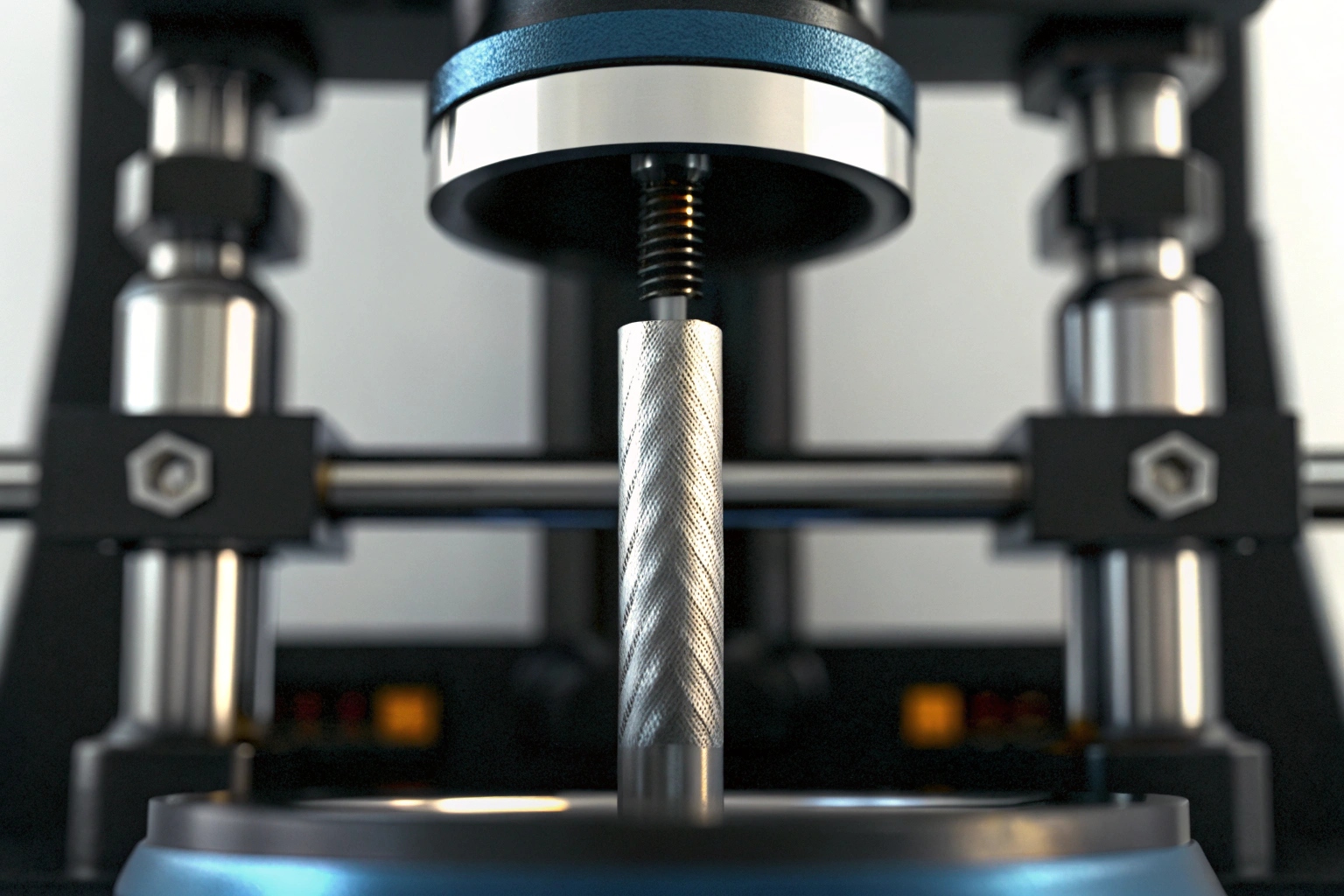

What mechanical property tests (e.g., hardness, tensile strength) do you perform?

Applying mechanical tests for raw materials 7 is fundamental for confirming their operational resilience. My strategies incorporate rigorous testing to verify mechanical properties like hardness and tensile strength.

Mechanical property tests, including hardness and tensile strength verification, facilitate the evaluation of material durability and resistance to operational stresses.

Dive Deeper

Mechanical testing involves various techniques to assess raw material integrity. Hardness testing 8 evaluates surface strength, while tensile tests 9 measure material elasticity and breakpoint.

Mechanical Testing Procedures

| Test Type | Method | Significance |

|---|---|---|

| Hardness Test | Rockwell/Brinell | Confirms surface resistance |

| Tensile Test | Universal Testing Machine | Evaluates elasticity and strength |

These tests provide insight into material performance under stress. They guide adjustments in machining and manufacturing processes, ensuring product longevity.

Hardness and Tensile Testing Explained

Standard tests like Rockwell or Brinell measure surface resilience. Tensile tests identify precise material strength thresholds, underpinning operational reliability.

How do you inspect critical components like seals and bearings before assembly?

Inspections of seals and bearings 10 are vital for guaranteeing seamless assembly operations. My processes prioritize these inspections to prevent system failures and ensure integration compatibility.

Effective inspection of seals and bearings confirms the components’ readiness for assembly, ensuring proper fitting and minimal operational risk.

Dive Deeper

Inspection protocols for seals and bearings assess physical and mechanical attributes. Verification includes dimension accuracy and resistance factors.

Seal and Bearing Inspection Standards

| Component | Inspection Focus | Methodology |

|---|---|---|

| Seals | Hardness and flexibility | Tensile strength tests |

| Bearings | Dimensional accuracy and rotation smoothness | Fatigue testing |

Intensive evaluations identify surface imperfections and verify component endurance. This prevents assembly snags and operational inefficiencies.

Precision in Critical Component Inspections

Comprehensive checks for seals and bearings ensure dimension precision and fatigue resistance. This maintains product reliability and enhances lifecycle performance.

Can I get a copy of the incoming material test report (MTR) for my order?

Providing comprehensive Material Test Reports (MTRs) affirms transparency and quality validation. I ensure MTR availability, reinforcing customer trust and alignment with manufacturing standards.

MTRs guarantee verification of material properties and specifications, bolstering confidence in product compliance with industry standards.

Dive Deeper

Material Test Reports provide essential insights into raw material composition and properties. These reports deliver detailed analysis supporting quality assurance strategies.

Components of Material Test Reports

| Report Element | Description | Importance |

|---|---|---|

| Material Certification | Confirms compliance | Ensures standard adherence |

| Chemical Analysis | Details elemental composition | Validates material integrity |

| Mechanical Property Results | Summarizes tests | Confirms operational readiness |

MTRs serve as critical documents in compliance verification, offering clarity on material specifics. This transparency fosters accountability and customer satisfaction.

Utilizing MTRs for Quality Assurance

Material Test Reports provide a detailed account of material attributes, supporting informed decisions and confirming product standards compliance.

Conclusion

Quality inspection processes for undercarriage parts for excavators & bulldozer are essential for ensuring material integrity and operational reliability. Standardized protocols mitigate risks and improve product performance consistency.

Footnotes

1. Overview of quality benchmarks in heavy machinery manufacturing. ↩︎

2. Guide to compliance and regulatory standards for industrial parts. ↩︎

3. Best practices for implementing raw material QC processes. ↩︎

4. Exploring new technologies in material inspection and metrology. ↩︎

5. Technical guide on methods for steel chemical analysis. ↩︎

6. Detailed explanation of how OES technology works for metal analysis. ↩︎

7. Learn about the different types of mechanical testing for metals. ↩︎

8. Compares different hardness test methods like Rockwell and Brinell. ↩︎

9. Understand what tensile testing reveals about material strength. ↩︎

10. Importance of pre-assembly checks for critical components. ↩︎