Trying to get a detailed equipment list from a Chinese supplier can feel overwhelming due to the numerous options and technical specifications 1 involved. It is essential to understand what to expect to ensure you obtain reliable information.

In many cases, Chinese undercarriage parts for excavators & bulldozer suppliers 2 are prepared to share detailed equipment lists upon request by potential buyers. These lists will typically include specifications and details that give you a good overview of the supplier’s capabilities and ensure they can meet your requirements for high-quality parts.

Don’t stop now; we’ll explore more about what you should know and expect when requesting this info from suppliers.

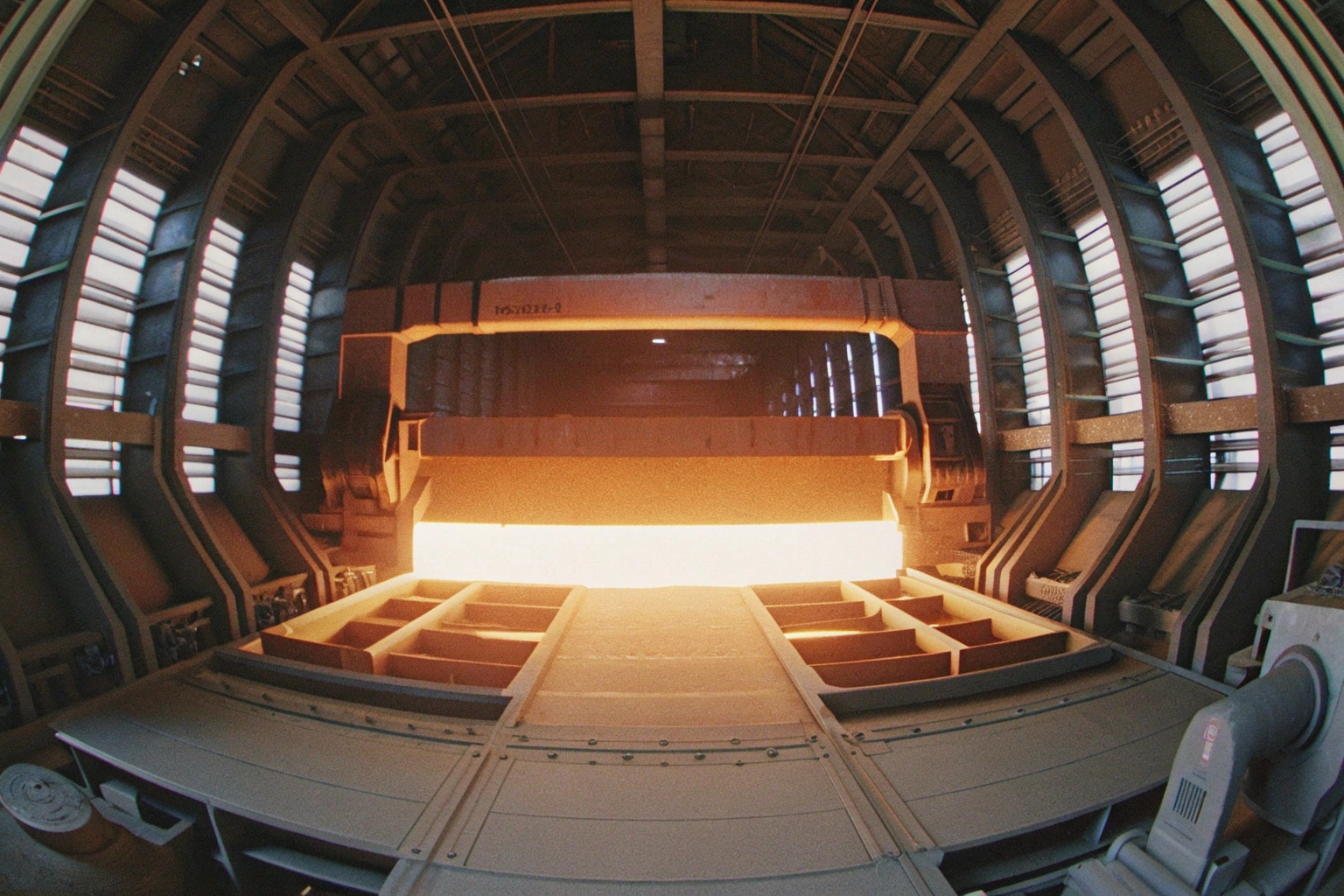

What types of CNC machines, forging presses, and heat treatment furnaces do you operate?

It’s crucial to identify the types of CNC machines 3, forging presses 4, and furnaces that your supplier uses. This helps determine their capacity and the quality of output they can achieve.

Suppliers often operate a range of CNC machines, forging presses, and heat treatment furnaces 5 to cater to various production needs. Specifics can involve sophisticated machines designed for precision and efficiency, ensuring the highest standards of manufacturing excellence.

Understanding the machine types used in the production process drives comprehension about capabilities and outputs. This is vital for you when assessing a supplier. CNC machines can hold high tolerances, key for producing exact parts like sprockets or track chains. Consider these machines’ ability to scale production or maintain product quality under increased demands.

Insights on Equipment Types

- CNC Machines: These function with precision, handling detailed and repetitive manufacturing tasks.

- Forging Presses: Essential for shaping high-strength materials into complex shapes.

- Heat Treatment Furnaces: The capacity to refine and enhance material characteristics and durability.

The supplier’s equipment’s sophistication may reveal their ability to handle intricate manufacturing challenges.

How old is your key manufacturing equipment?

Older machinery can indicate a supplier with a history in the industry, but cutting-edge technology 6 often points to innovation and enhanced product quality.

The age of key manufacturing equipment varies among suppliers. While older machinery may be well-maintained and productive, newer equipment often offers advanced features and capabilities that support higher efficiency and quality.

The equipment’s age often correlates with the technology and methods employed. Consider factors such as the maintenance history and updates the machines have undergone. Innovative machinery can facilitate quicker production cycles, scaling, and automated functions, thus impacting product consistency.

Factors Influencing Equipment Performance

- Age of Equipment: Older equipment may require frequent maintenance; newer machines deliver better precision.

- Maintenance and Upgrades: These determine how well machines can keep up with production demands.

- Automation Level: Modern automation can boost efficiency and streamline production cycles.

A supplier’s willingness to invest in state-of-the-art equipment 7 can be a testament to their commitment to quality and customer trust.

What is your factory’s total production capacity for track chains per month?

Knowing the production capacity directly affects lead times and product availability, impacting supply chain stability 8.

Suppliers generally outline their production capacity in terms of units manufactured per month. This is critical for ensuring they can meet your volume demands without compromising on quality or lead times.

Capacity details give insights into potential bottlenecks and production efficiency. Factors like employee expertise, machinery capacity, and technological tools shape these numbers. If a factory is operating near its maximum capacity, it may require consideration of alternative suppliers or solutions for long-term reliability.

Production Insights

| Aspect | Details |

|---|---|

| Volume per Month | Directly relates to supplier capability and readiness |

| Machinery Utilization | Efficiency and capacity utilization |

| Scalability | Ability to increase output promptly upon demand |

Clear visibility of production capabilities helps predict future performance and scaling potential.

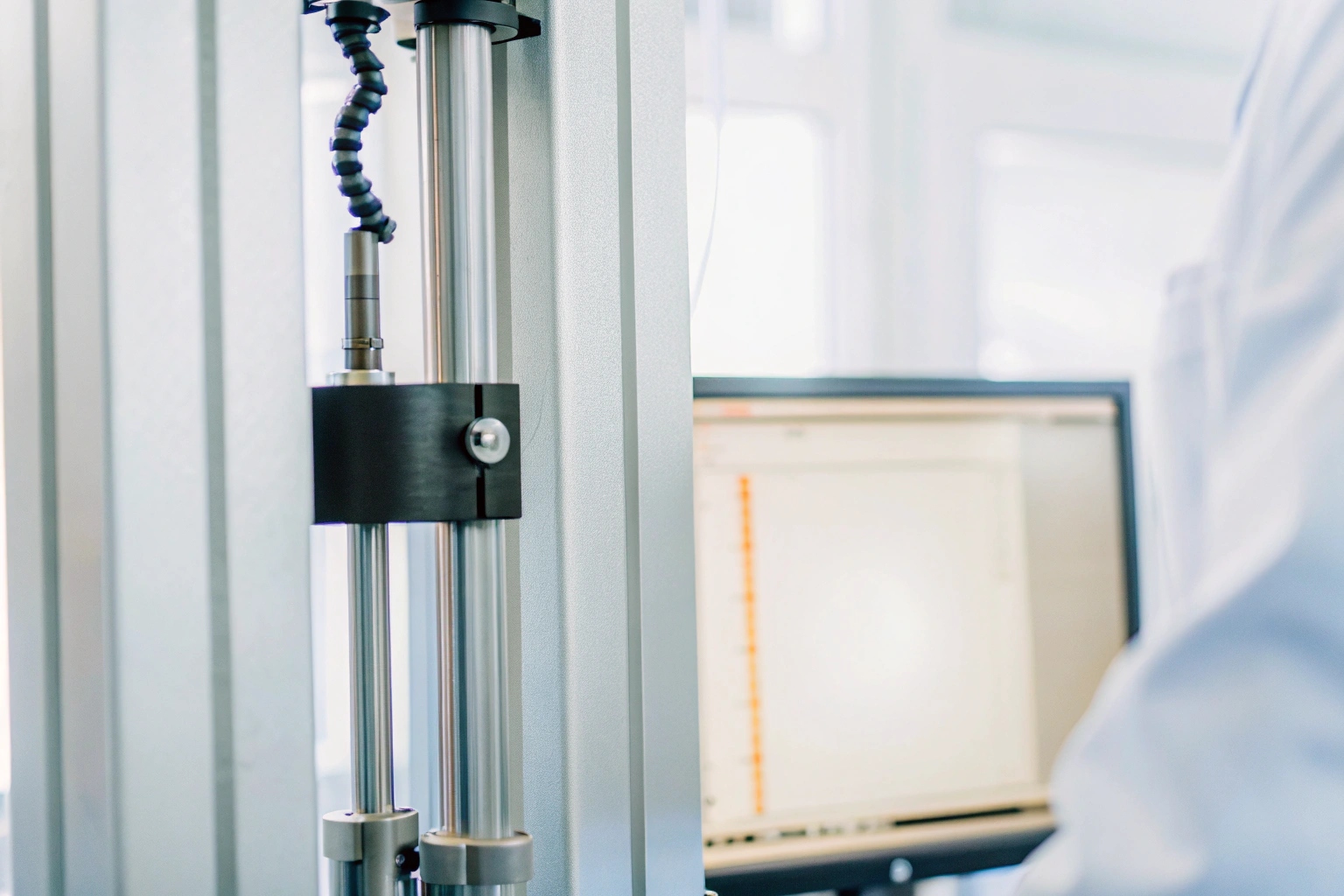

Do you have your own in-house testing laboratory?

In-house testing laboratories 9 are essential for quality assurance 10, confirming product specs and durability.

An in-house testing laboratory is indispensable for verifying a product’s compliance to standards needed for reliable operation. It ensures that components are tested rigorously before they leave the factory.

Quality control facilities are indicative of a supplier’s commitment to product integrity. These labs conduct various tests, examining aspects such as material strength, durability, and wear-resistance. Assurance via laboratories can reduce product failures and build confidence in the supplier’s offerings.

Laboratory Capabilities

| Quality Control Aspect | Testing Type |

|---|---|

| Material Strength | Tension, compression, and impact tests |

| Component Wear | Abrasion resistance evaluated over simulated usage |

| Compliance Validation | ISO standards and certifications confirmation |

A supplier with robust testing will likely outperform, delivering more reliable products that meet stringent market requirements.

Conclusion

Obtaining a detailed equipment list from your supplier is crucial for evaluating their capabilities and ensuring they can meet your demands efficiently and reliably.

Footnotes

1. Understand what technical details to ask for in undercarriage parts for excavators & bulldozer. ↩︎

2. A guide to vetting and selecting heavy equipment suppliers in China. ↩︎

3. See how CNC machining delivers precision components for heavy machinery. ↩︎

4. Learn about the forging process for high-strength metal parts. ↩︎

5. Explore how heat treatment improves metal durability and strength. ↩︎

6. Discover the latest trends in manufacturing and production technology. ↩︎

7. Benefits of suppliers investing in modern production machinery. ↩︎

8. Strategies for building a resilient and stable industrial supply chain. ↩︎

9. The importance of in-house labs for manufacturing quality control. ↩︎

10. Best practices for implementing quality assurance in manufacturing. ↩︎