Maintaining optimal quality control is a major struggle for any supplier, but advanced testing methods 1 can make all the difference. At my company, I’ve seen how quality fluctuates and impacts our reputation.

Advanced testing capabilities are essential for verifying precise dimensional accuracy, material properties, and component durability. Suppliers with CMMs and profilers ensure high standards, delivering parts with minimal risk of defects. Effective quality control processes can help strengthen client relationships and reduce costly returns 2 or complaints. Here’s how:

Do you use a CMM (Coordinate Measuring Machine) to check complex parts like sprockets?

Precision is everything. Imagine discovering a defect in a complex sprocket 3 after delivery—it is an issue no supplier or client wants. I’ve experienced the stress of receiving mismatched components myself.

Absolutely. Suppliers often deploy Coordinate Measuring Machines (CMMs) to check complex parts like sprockets, ensuring each dimension aligns with specified tolerances. This practice ensures accuracy and reduces potential assembly issues.

CMMs offer a level of precision in measuring dimensions 4 not achievable through manual inspections. The process begins with placing components on a CMM, which uses a probe to touch and measure various points on the part. This information is then compared with 3D CAD models 5, verifying that every specification is meticulously met. CMMs can inspect a range of parameters, including geometric tolerances like flatness or concentricity 6, making them invaluable.

Modern 5-axis CMMs 7 extend these capabilities by measuring complex GD&T features 8 such as parallelism and perpendicularity. They enable rapid validation during First Article Inspection (FAI) 9, ensuring part geometry matches expected design standards. This proactive approach helps catch inaccuracies early, mitigating downstream issues.

Precision measuring tools also play a critical role in failure analysis 10. By using CMM data, defects in field-failed components can be understood and addressed. This iterative improvement enhances both product durability and client satisfaction. Ultimately, detailed inspections with CMMs safeguard part integrity, aligning production processes with client expectations and international quality benchmarks.

Can you perform surface roughness and profile tests on sealing surfaces?

Undetected roughness or inconsistent profiles on sealing surfaces lead to premature wear and leakage issues—problems I’ve seen erode trust between suppliers and clients over time.

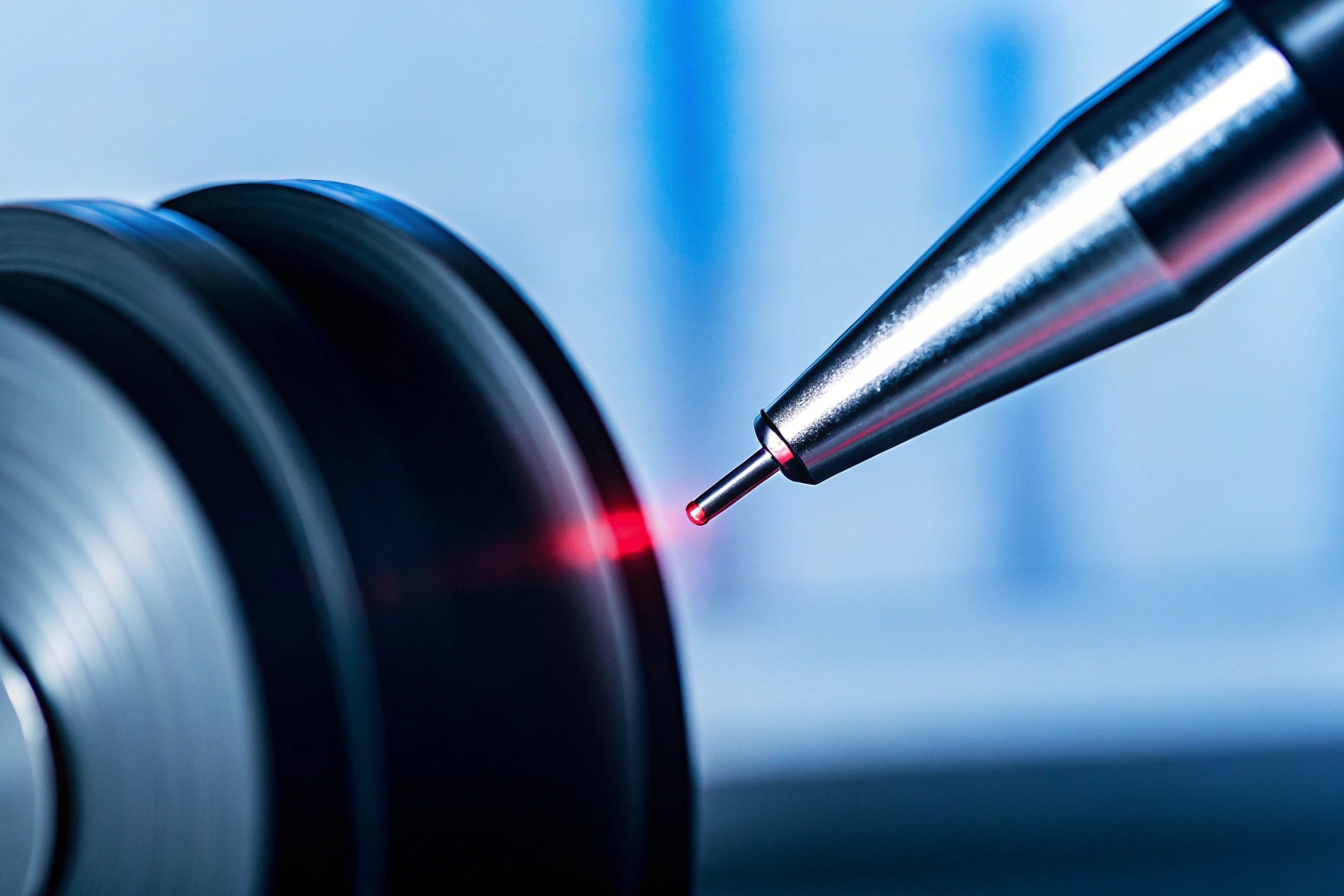

Yes, we can. Profilometers are employed to perform surface roughness tests on sealing surfaces, ensuring that texture, peaks, valleys, and topography meet industry standards. This confirms minimal friction and adequate wear resistance.

Surface finish dictates critical factors such as friction and wear resistance. Profilometers, both laser and tactile types, measure the topography of sealing surfaces with high accuracy. Capturing surface roughness profile aids in ensuring components perform reliably in field operations. These measurements are crucial for avoiding leaks, maintaining tight seals, and extending part lifecycle.

Surface data influences lubricant retention, impacting overall equipment efficiency. Furthermore, it is vital for coating adhesion, enhancing protection against corrosion and abrasion. Regular profiling inspections ensure consistent quality, bridging the gap between expected and actual part performance.

Understanding these surface metrics helps engineers optimize the manufacturing process to match targeted specifications. By incorporating surface roughness testing, suppliers effectively uphold product quality while reducing end-user risk. These evaluations serve both immediate and long-term interests, improving client trust through measurable and demonstrable quality assurance.

Do you have equipment to test the performance of seals and floating seals?

Floating or stationary, faulty seals can cause breakdowns and operational downtime. This potential disruption points to the acute need for reliable seal testing, something I’ve prioritized in past project planning.

We absolutely do. Our facilities include equipment for testing seal performance, specifically simulating operational conditions to ensure reliability of both seals and floating seal assemblies against specified standards.

Seal testing simulates real-world conditions, evaluating parts under pressure, temperature, and environmental changes. This process identifies potential weaknesses before deployment, minimizing risks of failure. Tests such as leak detection under exaggerated conditions expose performance deficiencies that might otherwise go unnoticed.

To maintain high standards, monitoring devices measure endurance over repeated cycles. Tests assess wear, material compatibility, and stress endurance. Ultimately, these evaluations aid engineers in validating designs, ensuring they withstand expected operational demands.

Floating seals, essential for protection against contaminants, face rigorous examination. These seals are crucial in adverse environments where contamination and pressure differentials are common. Validating their performance ensures smooth vehicle operation and leads to fewer field issues.

Testing seals thoroughly helps in selecting suitable materials and confirms optimal design, forming part of a comprehensive quality assurance strategy. Overall, these efforts deflect potential constraints that could disrupt client operations, aligning products with their specific service requirements.

How does this advanced testing reduce my risk of receiving defective parts?

The stakes are high—receiving defective parts could jeopardize not only revenue but also customer trust, something we fought hard to build over time.

Incorporating advanced testing processes significantly minimizes the risk of receiving defective parts by ensuring every component meets stringent quality standards. Reliable testing detects flaws early, safeguarding against lapses in design or manufacturing.

Advanced testing acts as a safeguard, filtering out defects before distribution. This systematic approach involves a suite of checks, including non-destructive testing methods like ultrasonic or magnetic particle inspections. Such techniques detect subsurface flaws without impairing part integrity, proving indispensable in quality management.

Further examinations include heat treatment verification using metallurgical tests, checking for hardness levels crucial for mechanical integrity. Ion emission spectrometry analyzes material composition, confirming adherence to required metallurgical specifications. Armed with this data, suppliers can provide guarantees on durability and compatibility.

Testing frameworks contribute to predictive maintenance models, utilizing actual field data to adjust manufacturing practices and refine design specifications. This synergy of testing and process refinement blocks potential defects at origin. Thus, clients gain from both high-quality deliveries and an increasingly reliable supply chain.

Suppliers also leverage real-time monitoring systems and IoT devices to collect data, offering transparency and continuous improvement. This proactive stance places client needs at the center, reducing risks while fostering long-term reliability in component supply.

Conclusion

Advanced testing practices in undercarriage parts for excavators & bulldozer manufacturing ensure you receive reliable, high-quality components, minimizing potential defects and operational risks.

Footnotes

1. Overview of advanced testing methods in manufacturing quality control. ↩︎

2. Strategies for reducing costly product returns through better quality assurance. ↩︎

3. Learn about common manufacturing defects found in industrial sprockets. ↩︎

4. Guide to high-precision dimensional metrology and inspection. ↩︎

5. How 3D CAD models are used for inspection and verification. ↩︎

6. Explanation of geometric tolerances like flatness and concentricity. ↩︎

7. Capabilities and benefits of 5-axis Coordinate Measuring Machines. ↩︎

8. What is Geometric Dimensioning and Tolerancing (GD&T)? ↩︎

9. The process and importance of First Article Inspection (FAI). ↩︎

10. How precision measurement aids in product failure analysis. ↩︎