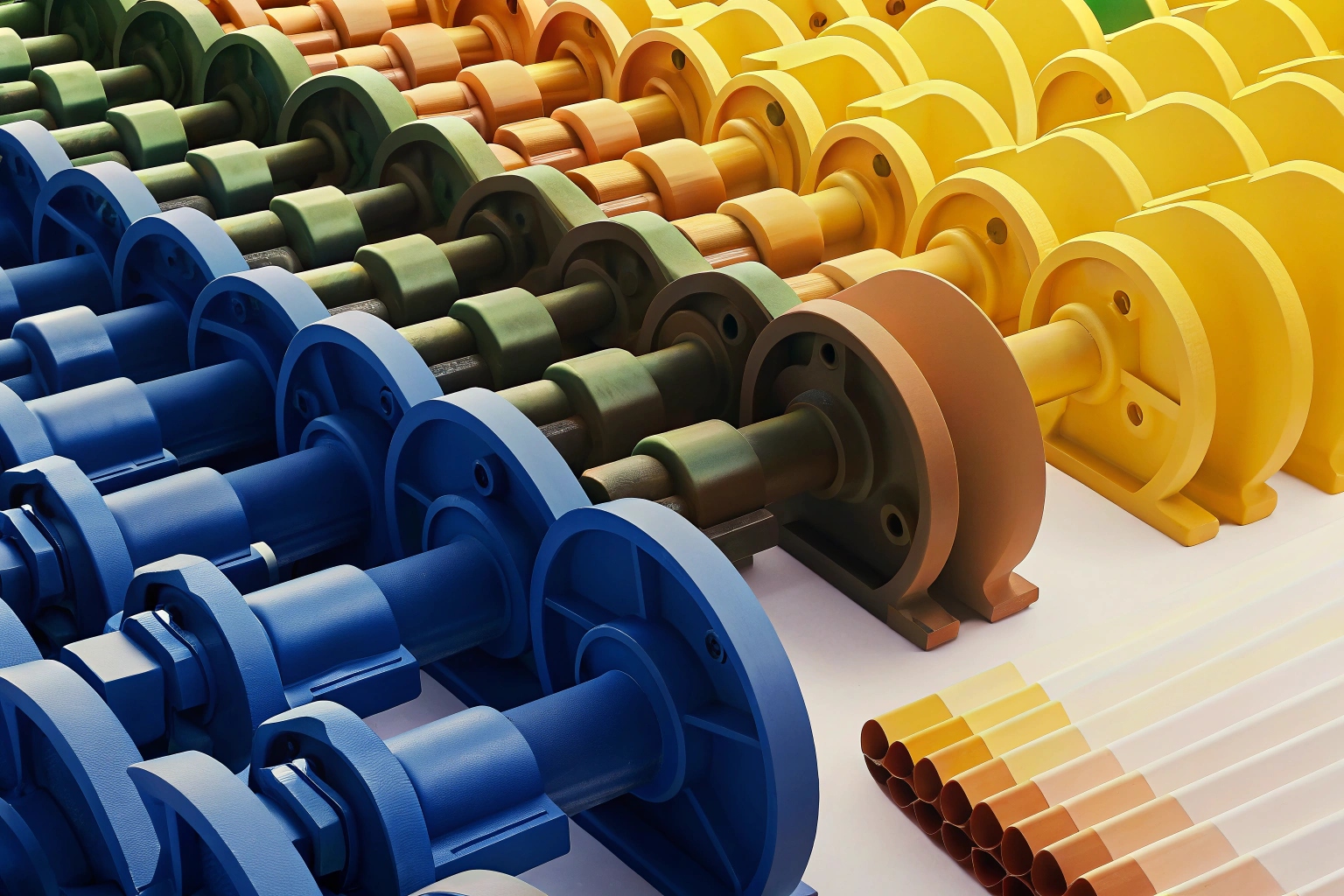

Undercarriage parts face tough environments. So, I ensure high standards for painting and coating, meeting industry requirements for protection and durability.

Undercarriage parts require precise coating standards to withstand harsh environments. Standards like ASTM 1, ISO 2, and SSPC 3 regulate these coatings, ensuring corrosion resistance and adhesion. Using rust-resistant primers and durable coatings, such as powder or epoxy, prevents degradation.

Understanding painting and coating standards is crucial for optimal performance of undercarriage parts for excavators & bulldozer. This ensures customer satisfaction and reduces maintenance costs.

What kind of paint do you use (e.g., primer, epoxy, powder coating)?

Primers and epoxy coatings 4 add a protective layer to undercarriage parts for excavators & bulldozer. Powder coatings 5 provide durability. These methods ensure robust protection against environmental challenges.

We utilize primers, epoxy, and powder coatings for undercarriage parts for excavators & bulldozer. Primers help with adhesion and corrosion prevention. Epoxy provides superior protection in harsh conditions. Powder coatings resist chipping and other surface damage.

Different paint options deliver varied benefits. Powder coating is known for its durability, making it popular for undercarriage parts for excavators & bulldozer. Advantages include resistance to corrosion and wear, essential for heavy-duty applications. Epoxy paints are recommended for parts exposed to severe conditions. They offer strong adhesion and create a protective shield against environmental factors. Primers prepare the surface of parts, ensuring that subsequent layers adhere well and enhance the lifespan of undercarriage components.

Paint Options for Undercarriage Parts for excavators & bulldozer

| Paint Type | Benefits | Recommended For |

|---|---|---|

| Primer | Enhances adhesion and corrosion resistance | All components |

| Epoxy | Excellent protection in harsh environments | Extreme conditions |

| Powder Coating | Durable and resistant to chipping | All components |

How do you test for paint thickness (film thickness) and adhesion?

Testing paint adhesion and thickness ensures durability. Key methods address common concerns. I focus on these standards for superior outcomes.

Testing methods measure paint adhesion and thickness precisely. Standards like SSPC-PA 2 6, ASTM D3359 7, and GB 9286 guide these processes. Magnetometers measure film thickness without damage, while tape tests assess adhesion effectively.

Several procedures aid in the assessment of paint performance. For paint thickness, dry film thickness (DFT) measurement remains essential. Equipment utilizing magnetic induction or eddy current helps measure coatings on different substrates. Adhesion tests, such as the cross-hatch test 8, evaluate the grip between the paint and metal surface. Standards dictate the conditions and expected outcomes for testing, providing benchmarks for quality control.

Paint Testing Standards

| Standard | Description | Application |

|---|---|---|

| SSPC-PA 2 | Measures dry film thickness | Quality control |

| ASTM D3359 | Cross-hatch adhesion test | Adhesion assessment |

| GB 9286 | Grid-like cut test for main adhesion | Industrial adherence check |

Can I specify a custom RAL color for my branded parts?

Custom colors intensify brand identity. I explore options for specific RAL colors to match requirements while ensuring compliance with standards.

Clients can request custom RAL colors for branded parts. This customization strengthens brand visibility. Paint coatings with specified colors maintain quality and meet industry standards.

Offering custom colors is vital for branding. The RAL color system 9 provides a wide array of shades, facilitating personalized selections which cater to specific branding needs. The system ensures consistent color reproduction across different batches and locations. Factories adhere to exact formulations to achieve desired hues, ensuring the brand maintains its intended appearance. This personalization does not compromise paint’s protective qualities. Industries aim for vibrant aesthetics without sacrificing performance.

Custom RAL Colors

| RAL Color | Application | Benefit |

|---|---|---|

| Custom RAL | Branding-specific coatings | Enhances brand identity |

| Standard RAL | General-purpose applications | Ensures consistency |

How long is the paint expected to last and resist corrosion?

Longevity is critical for paint. I prioritize standards for paint durability, ensuring that undercarriage parts for excavators & bulldozer withstand demanding conditions.

Paint coatings on undercarriage parts for excavators & bulldozer have a long lifespan, resisting corrosion for years. Standards like ISO 12944 10 define requirements, ensuring performance in varying environments. Appropriate paints offer reliable protection, mitigating wear and tear.

Paint longevity depends on several factors. The environment it’s exposed to, maintenance practices, and coating quality all impact its duration. ISO 12944 outlines classifications for different corrosive environments. Selecting and applying appropriate layers within these standards ensures undercarriage parts for excavators & bulldozer remain resilient. Routine inspections and maintenance practices further enhance their effectiveness, prolonging paint’s lifespan and minimizing repair needs. Compliant coatings withstand extensive exposure, maintaining appearance and functionality much longer than unregulated ones.

Paint Durability Factors

| Factor | Impact on Longevity | Maintenance Needed |

|---|---|---|

| Environment | Corrosive elements | Regular inspections |

| Coating Quality | Paint formulation and application | Protective measures |

Conclusion

Painting standards protect undercarriage parts for excavators & bulldozer from corrosion and wear, ensuring durability and performance in challenging conditions.

Footnotes

1. Explore ASTM International’s role in developing technical standards. ↩︎

2. Learn about the International Organization for Standardization’s quality management. ↩︎

3. See the Society for Protective Coatings (SSPC) standards. ↩︎

4. Understand how epoxy coatings provide strong adhesion and protection. ↩︎

5. Discover the benefits and application process of powder coatings. ↩︎

6. Read the SSPC-PA 2 standard for measuring dry film thickness. ↩︎

7. Review the ASTM D3359 standard test method for adhesion. ↩︎

8. Learn the procedure for conducting a cross-hatch adhesion test. ↩︎

9. Explore the RAL color matching system for paints and coatings. ↩︎

10. Guide to ISO 12944 standards for corrosion protection. ↩︎