Batch traceability in undercarriage parts for excavators & bulldozer is essential for ensuring the quality and reliability of components. I always aim to work with suppliers who prioritize thorough tracking methods to prevent issues and enhance accountability.

Suppliers use various technologies to manage traceability, such as serial numbers 1, QR codes, and RFID. These methods help track parts throughout their lifecycle, linking each component back to its production date and raw material. Additionally, advanced ERP systems 2 integrate traceability with purchase orders, maintaining detailed records for years.

A comprehensive approach to part traceability is crucial for suppliers and their clients. It ensures compliance, enhances safety, and builds trust. I find reassurance in knowing that each part can be traced, providing confidence in every product we receive.

Is every part marked with a unique serial number or heat treatment batch code?

Serial numbers and heat treatment batch codes are vital for tracking parts from production through usage. I’ve seen firsthand how suppliers leverage these identifiers to monitor parts’ lifecycles and ensure quality.

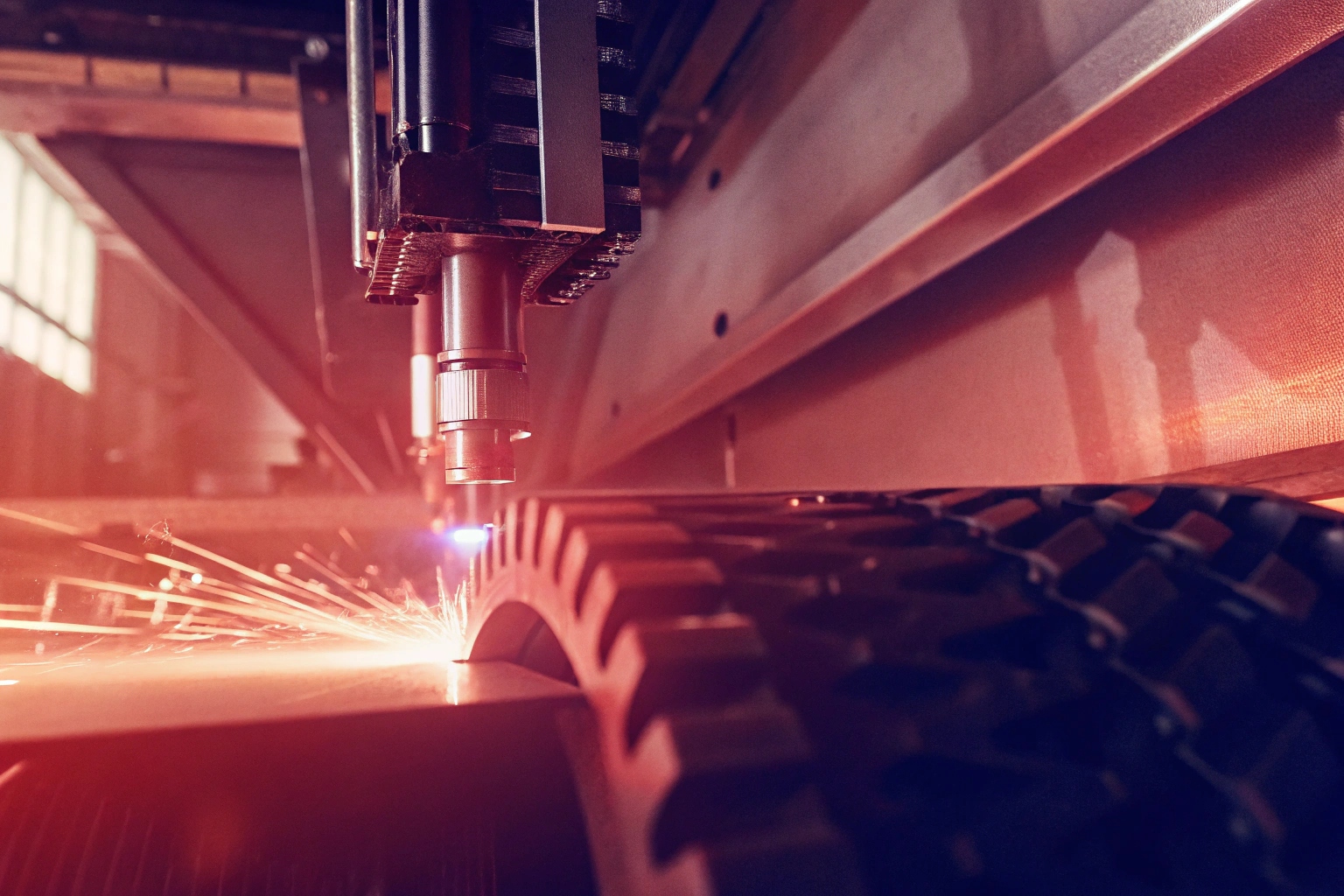

Products often have permanent marking methods, like laser engraving or dot peen marking, directly applied to metal components. This enables efficient tracing of individual serial numbers and batch codes. QR codes also play a role by linking to detailed part histories 3 from heat treatment to final inspection.

Understanding Serial Number Marking

Applying serial numbers directly offers precise management of component lifecycles and authenticates parts. It helps in tracking performance wear and validating warranty claims. Suppliers use permanent markings 4 for reliability and to combat counterfeiting.

| Pros | Cons |

|---|---|

| Enhances traceability | Requires initial setup cost |

| Validates warranty claims | Complex integration with other systems |

| Acts as anti-counterfeiting measure | Must update database regularly |

Marketers need reliable data to ensure that each part’s authenticity is maintained, so investing in robust marking techniques is essential.

Can I trace a failed part back to its specific production date and raw material lot?

Tracing back to raw materials is crucial. With advanced systems 5, tracing starts as soon as materials arrive. It’s essential for supply chain transparency and product responsibility.

Traceability begins with tagging raw materials with unique identifiers and supplier info. These tags then link components throughout production. Software systems capture detailed batch data, integrating floor scanners with MES and ERP software 6 for seamless traceability back to raw materials.

In-Depth Traceability Processes

Traceability systems help manage batch lifecycle details, like material test records. Suppliers differentiate between lot traceability for batches and item-level serialization for critical components. This granularity ensures accuracy and supports rapid action in recalls or investigations.

| Batch Type | Traceability Focus |

|---|---|

| Lot Traceability | For bolts, bushings |

| Item-Level Serialization | For major components like track frames |

Linking parts back to their raw material and production data significantly boosts reliability. As businesses demand more accountability, it’s not just an option but a necessity to get comprehensive traceability solutions in place.

Does your ERP system link my PO number to your production batches?

ERP systems 7 are fundamental in ensuring seamless operation between purchase order numbers and production batches. I look for suppliers with advanced software capabilities that can meet this demand.

Many suppliers use ERP systems to link PO numbers to specific batches. This connection ensures orders are fulfilled accurately and traceability records are thoroughly maintained. From receipt to final shipment, every detail is logged in these systems.

Role of ERP Systems in Traceability

ERP systems handle complex interactions between order specifics and production data. Suppliers can manage inventory, orders, and traceability effectively, ensuring transparency and smooth transactions.

| ERP Feature | Benefit |

|---|---|

| PO Linking | Enhances accuracy |

| Production Data Management | Ensures compliance |

| Record Maintenance | Supports long-term tracking |

Companies invest heavily in ERP systems to provide crucial connections in their production processes. For clients, it means reassurance of timely delivery, accurate tracking, and service reliability, elevating overall satisfaction.

How long do you maintain these traceability records?

Maintaining traceability records 8 for an extended period is a common practice among suppliers. I believe in working with partners who prioritize this as it ensures ongoing support and accountability.

Suppliers maintain traceability records for several years, ensuring that any component issues can be quickly addressed. Systems log complete transaction and movement data, encouraging compliance and quality assurance across the board.

Long-Term Traceability Management

Diligently keeping traceability records helps suppliers prove adherence to standards and assure customers. Compliance with certifications like ISO 9001 9 relies on comprehensive auditing and tracking protocols.

| Records Duration | Advantages |

|---|---|

| Long-term (years) | Ensure compliance |

| Detailed Logs | Quick issue resolution |

| Extensive Database | Supports operational integrity |

For clients, long-term record maintenance is a key part of supplier trust. It’s not simply about resolving past issues but ensuring future reliability and collaboration, concrete proof of supplier commitment and professionalism.

Conclusion

Comprehensive traceability is a cornerstone of reliable supply chains. As components become increasingly critical, suppliers’ ability to track products from raw material to delivery is non-negotiable. Such systems ensure quality, accountability, and trustworthiness, essential elements in a thriving business partnership.

Footnotes

1. Understand the importance of serial numbers in supply chain management. ↩︎

2. Explore how ERP systems streamline traceability processes. ↩︎

3. Detailed insight into part lifecycle management systems. ↩︎

4. Discover permanent marking methods for anti-counterfeiting. ↩︎

5. Learn about advanced traceability systems in manufacturing. ↩︎

6. Understand MES and ERP software integration for traceability. ↩︎

7. An overview of ERP systems and their role in production. ↩︎

8. Guide to maintaining traceability records for compliance. ↩︎

9. Insights into ISO 9001 certification requirements. ↩︎

10. Introduction to the basics of RFID technology in tracking. ↩︎