Modern businesses face challenges in ordering the right quantities of parts. I often struggle with determining the correct MOQ 1 for my mixed SKU undercarriage parts for excavators & bulldozer containers.

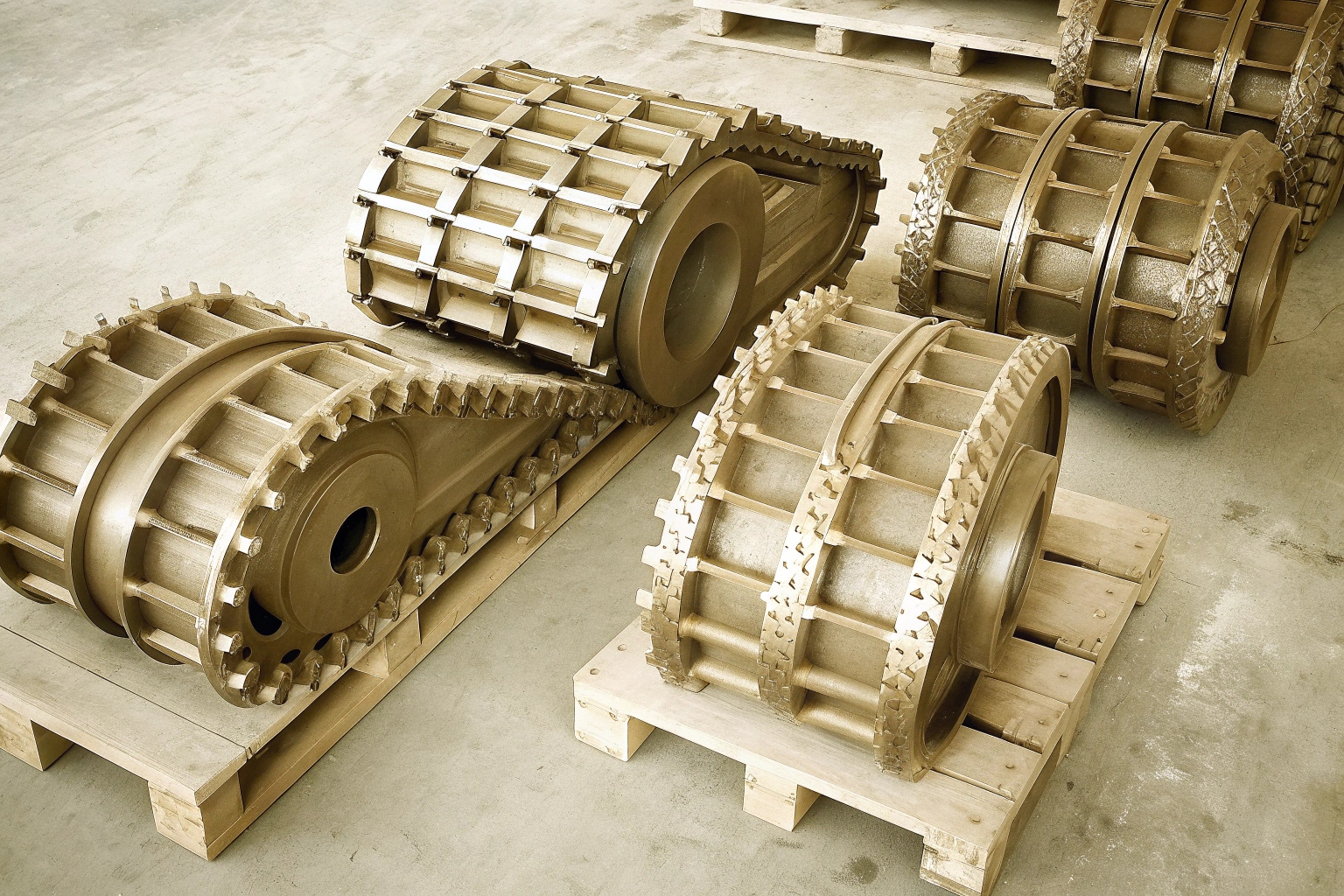

The minimum order quantity (MOQ) for mixed SKU undercarriage parts for excavators & bulldozer containers typically ranges from 50 to 100 units per SKU. Suppliers often require the total combination to reach around 500 units. This allows businesses to balance various parts—like rollers, sprockets, and links 2—within the same shipment, optimizing cost and efficiency.

Understanding the MOQ is crucial for planning. Balancing different parts for shipping can be complex, but meeting the MOQ helps ensure smoother operations.

| SKU Type | Typical MOQ per SKU | Total MOQ for Mixed Container |

|---|---|---|

| Rollers | 50 | 500 |

| Sprockets | 50 | 500 |

| Links | 50 | 500 |

Can I mix different parts (rollers, sprockets, links) on the same pallet?

Sometimes, when planning shipments, I wonder about the flexibility of combining parts on a pallet 3.

Multiple parts can be mixed on the same pallet, as long as the combination meets the overall MOQ requirements. This flexibility allows for optimized loading and efficient use of space, accommodating varied inventory needs within a single shipment.

Mixing different parts requires strategic planning. Careful coordination is needed to ensure compatibility and protection of parts during transport. It’s essential to avoid damage and keep inventory organized. Regular checks on stability and weight limit adherence are necessary to prevent issues during shipping. Using robust packaging 4 and marking every SKU clearly can help streamline the process.

| Part Type | Mixing Feasibility | Precaution |

|---|---|---|

| Rollers | Yes | Ensure protection |

| Sprockets | Yes | Avoid direct contact |

| Links | Yes | Use sturdy boxes |

What is the smallest packaging unit (e.g., box, pallet) per SKU?

Packaging decisions are critical to shipping efficiency. I often focus on understanding the smallest unit per SKU for effective logistics.

The smallest packaging unit per SKU typically depends on the part size and type. Smaller items like bolts and bearings 5 may come in sturdy bags and boxes, while larger parts, such as track links, are often packaged in pallet-sized units.

Choosing packaging units involves more than just size. Logistics and dimension restrictions are vital. Follow stacking principles like heavy-bottom stacking and maintain load limits to avoid damage. Packaging weight affects manual handling, so units shouldn’t exceed safety limits. Protect parts using compatible buffers against pressure and moisture, ensuring model number clarity 6 for smooth customs clearance.

| Part Type | Smallest Unit | Packaging Type |

|---|---|---|

| Bolts/Bearings | Box | Sturdy bags/Boxes |

| Track Links | Pallet | Pallet-sized units |

How do you optimize container loading for a mixed-parts order?

Shipping mixed orders involves complexity. I sometimes wonder about the best strategies for optimizing container loading 7 for varied parts.

Optimizing container loading for mixed parts involves strategic placement and balancing weight distribution. Proper arrangement avoids damage while maximizing space usage, allowing seamless transport of diverse inventory within a single container.

Effective container loading demands strategic planning. Balancing weight limits within containers ensures stable transport. Consider stacking and spacing principles to prevent part damage. Logistics require understanding of packaging dynamics, like heavy parts at the bottom and lighter items on top. Anticipate seasonal demand 8 and competition affecting shipping flexibility.

| Key Factor | Strategy |

|---|---|

| Weight Distribution | Balance load evenly |

| Part Arrangement | Heavy bottom, light top |

| Seasonal Considerations | Account for order fluctuations |

What is the cost difference between ordering LCL (Less than Container Load) versus a full container?

Cost-effectiveness is a major concern. I often weigh the benefits of choosing between LCL and full containers 9.

Opting for Less than Container Load (LCL) shipments significantly increases per-unit costs compared to full container loads. Full containers typically offer better cost efficiency due to fixed shipping rates and reduced handling fees, optimized by maximized space usage.

Understanding shipping options is crucial. LCL can accommodate smaller quantities, but costs rise with individual handling. Full containers reduce cost per unit by maximizing space and minimizing handling scenarios. Consider seasonal fluctuations 10 that might affect MOQ requirements and cost efficiencies, providing greater shipping flexibility.

| Shipping Method | Cost Impact | Advantages |

|---|---|---|

| LCL | Higher per unit cost | Smaller order flexibility |

| Full Container (FCL) | Lower per unit cost | Cost efficiency |

Conclusion

Optimizing parts orders requires understanding MOQ, pallet mixing, packaging units, and container use. Efficient shipping depends on strategic planning.

Footnotes

1. Explore how MOQ policies affect purchasing strategies. ↩︎

2. Understanding the impact of mixed SKU shipments. ↩︎

3. Guidelines on pallet mixing for efficient shipments. ↩︎

4. Importance of proper packaging in inventory management. ↩︎

5. Packaging strategies for small undercarriage parts for excavators & bulldozer. ↩︎

6. Ensuring customs clearance with clear labeling. ↩︎

7. Tips for maximizing container space with varied inventory. ↩︎

8. Planning for seasonal fluctuations in shipping demands. ↩︎

9. Detailed cost analysis between LCL and full containers. ↩︎

10. Seasonal impacts on MOQ and shipping costs. ↩︎