Imagine facing downtime because the right parts aren’t readily available when you most need them. It can be terribly frustrating. That’s why I explored the concept of kitting 1.

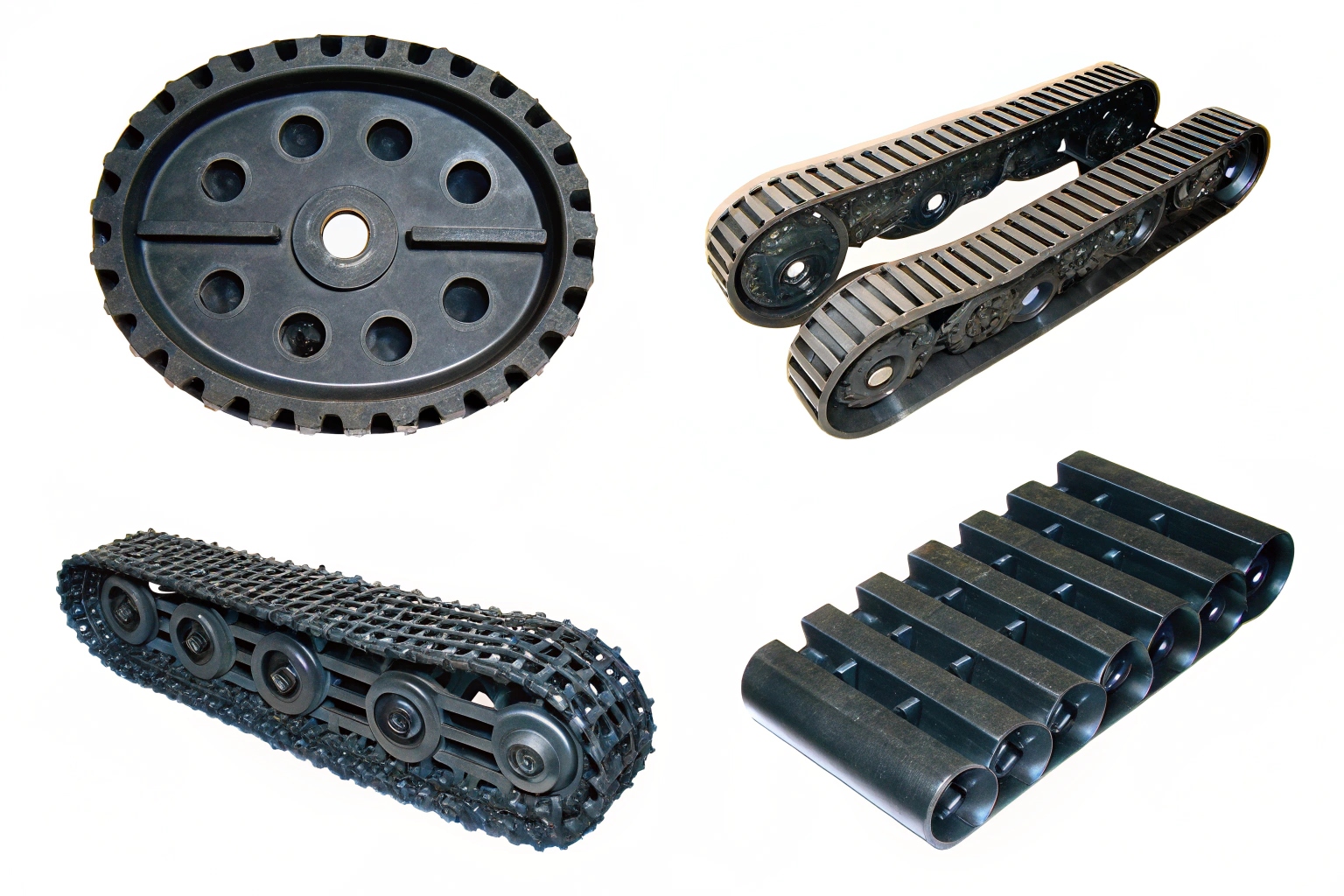

Kitting undercarriage parts for excavators & bulldozer involves bundling together parts like bolts, nuts, and rollers based on specific repair needs. This service is offered by many suppliers to increase repair efficiency, reduce ordering errors, and streamline inventory management. Custom kitting is designed to match repair requirements, ensuring the right parts are at hand, minimizing downtime and maximizing operational efficiency. Having kitted packages means repairs can be smoother and faster. It addresses the challenge of missing or mismatched parts, helping both warehouses and end-users optimize their repair processes 2.

Can you package a full set of track bolts and nuts for one track shoe?

I found myself wondering if there’s a more efficient way to get bolts and nuts for track shoes. Searching for individual parts can be time-consuming and error-prone.

Packaging a full set of track bolts and nuts for one track shoe is a common service offered by suppliers. This bundled package ensures that all necessary components are together, streamlining repair processes and minimizing the risk of missing parts during assembly. Packages are custom-made to fit specific machinery requirements and can dramatically improve repair efficiency by reducing the time spent searching for individual components.

Kitting bolts and nuts into a ready-to-go package simplifies the mechanics’ work. They don’t have to fumble through bins or risk using incorrect parts. By getting exactly what they need, repairs become quicker and more reliable.

Advantages of Track Shoe Kits

- Inventory Simplification 3: Reduces the number of inventory SKUs by consolidating parts into a single kit.

- Time Efficiency 4: Mechanics gain instant access to correct parts, thus saving time.

- Order Accuracy 5: Bundling ensures correct parts are sent and received for specific applications.

| Component | Functions | Benefits |

|---|---|---|

| Bolts & Nuts | Fastening | Ensures stability of parts |

| Kits | Convenience | Reduces logistics hassle |

What is the cost for creating custom-labeled repair kits for my customers?

Custom-labeling seemed like an additional benefit, but I wasn’t sure about the cost involved in doing so. It’s crucial to weigh the benefits against expenses.

Creating custom-labeled repair kits can vary in cost depending on the complexity and quantity of labeling needed. Suppliers typically factor in label design, material, and the extent of customization. Detailed labels that include serial numbers, part lists, and machine compatibility enhance identification and traceability. These kits provide added value by preventing mix-ups and facilitating smooth logistical operations. Costs are often offset by the benefits of efficiency and accuracy they bring to both distribution and end-user repair processes.

Custom-labeled kits can be a game-changer. By ensuring parts are correctly identified and traceable 6, repair activities are more efficient. While costs can vary, the gains in efficiency often justify the investment.

Breaking Down Costs

- Design Costs: Initial setup for label design, including logos and custom information.

- Material Costs: Quality materials ensure durability and clarity, impacting cost.

- Volume Discounts 7: Larger orders may benefit from reduced price per unit.

How does kitting help my warehouse and my end-users?

I’ve often thought about ways to improve our warehouse and end-user operations. Kitting seems to be a promising solution, but what truly are its benefits?

Kitting helps both warehouses and end-users by streamlining the storage and retrieval processes, reducing errors, and ensuring all necessary components are included in a single package. In warehouses, kitting simplifies inventory management by decreasing the number of separate SKUs, saving storage space, and making tracking more efficient. For end-users, kits reduce the likelihood of missing components during repairs, thus enhancing productivity and minimizing downtime. This transformation in operational efficiency leads to cost savings and improved satisfaction for customers and businesses alike.

Warehouses benefit significantly from kitting. It simplifies logistics, reduces stocking issues, and enhances space utilization 8. For end-users, the predictability of a fully stocked kit means quicker and more reliable repairs.

Benefits Across Stages

| Stage | Warehouse Benefits | End-User Benefits |

|---|---|---|

| Inventory | Consolidated stock management | Easy access to complete sets |

| Assembly | Reduced handling and sorting | Streamlined repair process |

| Efficiency | Faster order fulfillment | Reduced repair time |

What is the MOQ for creating a custom parts kit?

Considering the minimum order quantity (MOQ) for custom parts kits 9 seemed prudent. Better to know my options upfront.

The minimum order quantity (MOQ) for creating a custom parts kit varies across suppliers and depends on factors such as part complexity, kit customization level, and supplier capabilities. Some suppliers might offer low MOQs to encourage smaller orders, while others require larger orders to balance the costs of customization and packaging setup. It’s beneficial to establish a clear conversation with the supplier to align MOQ with expectations and ensure the right balance between cost-effectiveness and supply requirements.

Understanding the MOQ is crucial. A clear discussion with suppliers can resolve potential concerns about order sizes and help adapt orders to align better with our repair needs.

Factors Influencing MOQ

- Customization Complexity: Highly customized kits may require higher MOQs as they involve additional setup and materials.

- Supplier Capabilities: Larger suppliers may have higher MOQs but offer cost benefits at volume.

- Customer Demand 10: Aligns with customer order sizes and repair frequency.

Conclusion

Kitting undercarriage parts for excavators & bulldozer streamlines repairs, enhances efficiency, and reduces errors, benefiting warehouses and end-users alike.

Footnotes

1. Learn the basics of product kitting in logistics. ↩︎

2. Strategies for improving MRO (Maintenance, Repair, Operations) workflows. ↩︎

3. Guide to reducing SKUs and simplifying warehouse stock. ↩︎

4. See how kitting speeds up assembly and repair operations. ↩︎

5. Benefits of kitting for reducing picking and packing errors. ↩︎

6. The importance of part traceability in supply chain management. ↩︎

7. How bulk purchasing can reduce per-unit costs for supplies. ↩︎

8. Techniques for optimizing warehouse layout and storage. ↩︎

9. Explanation of MOQ and how suppliers calculate it. ↩︎

10. Understanding demand forecasting in inventory management. ↩︎