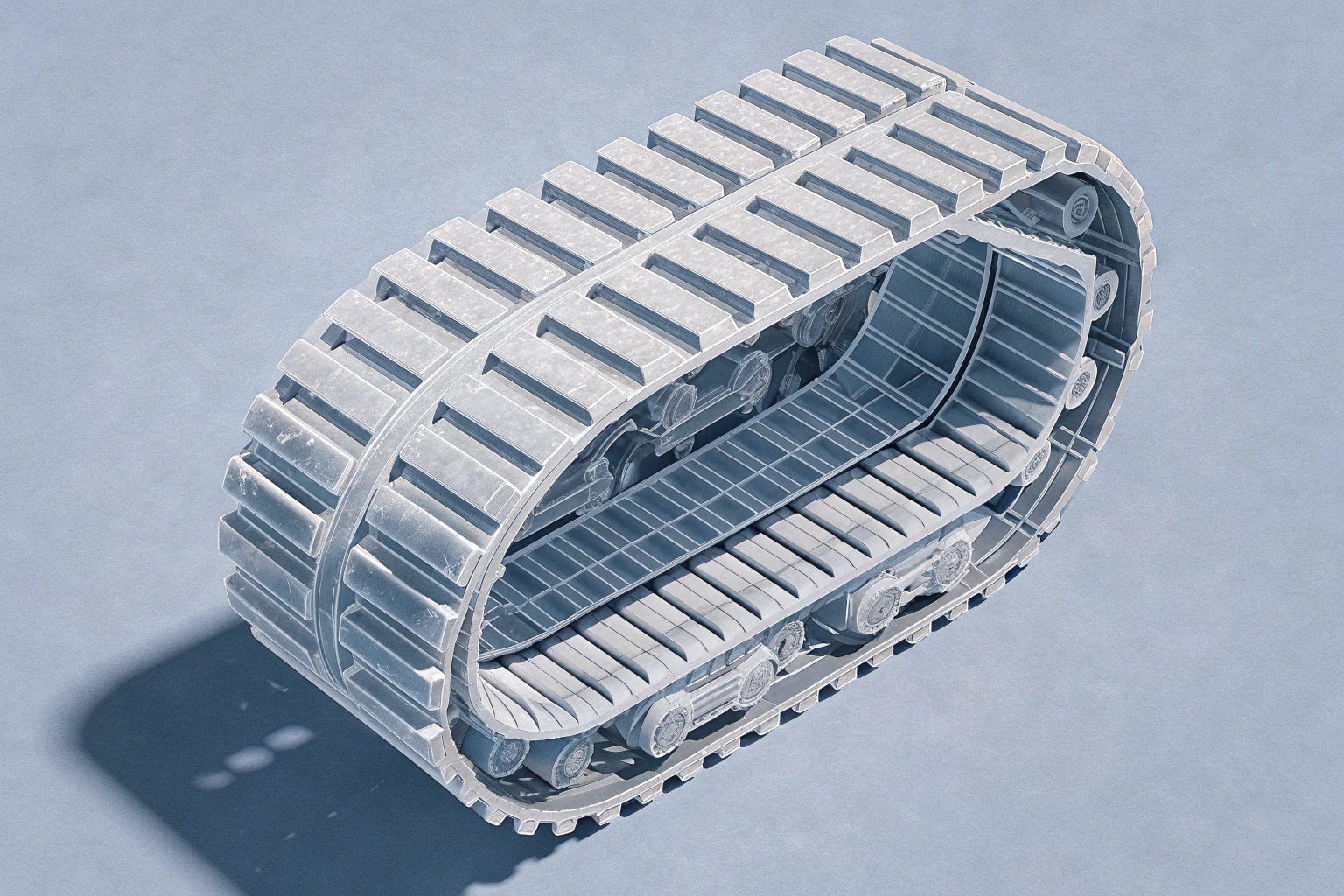

Selecting the right material and hardness for track rollers can feel overwhelming, especially with varying options on the market. Reflecting on my personal story, I always strive for the perfect balance between durability and performance in harsh conditions.

In my experience, forged from high-carbon or alloyed steels, such as 50Mn, 40Mn2, or 40Cr, track rollers are built to endure. The surface hardness ideally ranges between HRC 52 and HRC 58, critical for bearing heavy loads without wearing too quickly.

Understanding the complexities behind material selection and roller hardness can be daunting. Dive into how different steel grades shape manufacturing processes, offer varying levels of wear resistance, and their impact on overall product lifespan.

Steel Grades for Track Rollers

Track rollers undergo intense stress and friction, demanding robust material choices. Alloy steels 1, such as 50Mn and 40Mn2, are common in roller manufacturing. Their chemistry allows for high wear resistance while maintaining structural integrity.

| Steel Grade | Characteristics | Common Use |

|---|---|---|

| 50Mn | High Carbon | Standard use |

| 40Mn2 | Hard Toughness | Heavy-duty applications |

| 40Cr | Strong Core | Extreme Environments |

During production, opting for the correct steel grade is vital. The right choice depends on the environment in which the rollers will operate. For excavators working on rocky terrains or mining sites, track rollers forged from sturdy materials capable of absorbing shocks are essential.

Importance of Hardness

Hardness directly affects wear resistance. For track rollers, differential hardening 2 is key. The outer shell is tough for abrasion resistance, while the core remains softer to absorb impacts. This dual hardness ensures longevity without compromising roller function.

| Hardness Range | Attribute | Function |

|---|---|---|

| HRC 52-58 | Surface Hardness | Wear Resistance |

| HRC 30-35 | Internal Toughness | Impact Absorption |

It’s not only about the material but also the heat treatment processes used to enhance these properties. Induction hardening 3 followed by tempering helps achieve the perfect hardness balance.

What hardness range (HRC/HB) should my roller tread meet?

Harnessing the roller tread hardness for optimal performance can seem confusing without proper guidance. From my perspective, ensuring the surface is neither too soft nor brittle is paramount.

The roller tread should meet a hardness range, commonly specified between HRC 52 and HRC 58, for the surface. The internal core should be softer around HRC 30-35. This balance prevents premature wear and cracking.

Delve deeper into the reasoning behind specific hardness ranges for different roller components, considering their functional demands and potential operational challenges.

Surface Hardness Significance

The tread’s hardness dictates its wear resistance. Higher surface hardness, achieved through processes like induction hardening 4, ensures longevity. The surface can withstand repeated abrasion without rapid degradation.

Core Hardness Dynamics

The roller’s internal core hardness should be slightly less to absorb impacts. This setup helps prevent the roller from being too brittle, which might lead to cracks or breakages during operation.

| Component | Hardness (HRC) | Functionality |

|---|---|---|

| Outer Shell | 52-58 | Abrasion Resistance |

| Core | 30-35 | Shock Absorption |

When ensuring operational efficiency, understanding the role of hardness in each component can bring reliability. Proper heat treatment and hardness verification processes 5 such as Rockwell testing can ensure you meet these specifications consistently.

Can my supplier share heat-treatment charts and hardness maps?

Finding transparency in a supplier’s production process is often quite challenging. I recall probing my suppliers for detailed reports to clarify their manufacturing standards.

Most reputable suppliers should be able to provide heat-treatment charts 6 and hardness maps. These documents often outline their production process, ensuring accountability and quality assurance.

Explore how these documents can clarify manufacturing techniques, bolster confidence in the product quality, and protect against unexpected failures.

Heat-Treatment Charts

These charts are crucial for understanding how a roller’s hardness is achieved. They specify the induction hardening temperatures, duration, and tempering processes used to stabilize the steel.

| Heat-Treatment Process | Duration | Temperature (°C) | Result |

|---|---|---|---|

| Induction Hardening | 15 mins | 850 | Hard Exterior |

| Tempering | 2 hours | 200 | Tough Core |

A heat-treated product offers predictable wear characteristics and aids in long-term planning for replacements.

Hardness Maps

A hardness map details the hardness distribution across the roller surface. It assures uniform hardness that aligns with pre-determined specifications, making it essential for confirming the quality of each roller batch.

Requesting these documents requires building a relationship with suppliers, reinforcing the importance of collaborative discussions to ensure specifications are met.

How do I perform on-site hardness tests on delivered rollers?

Learning how to conduct hardness tests on-site after receiving rollers seemed like a daunting task at first. However, over time, I realized the importance of ensuring product quality firsthand.

On-site hardness tests are essential for quality control. Tools such as rebound hardness testers 7 or specialized files can serve this purpose, though less precise than laboratory methods.

Uncover the practical methods for quick on-site verification, understanding their precision and limitations in a real-world scenario.

Tools for On-Site Testing

Rebound hardness testers are portable, allowing quick checks of hardness levels. These tools measure the rebound height of a metal from the roller surface, indirectly reflecting hardness.

| Testing Method | Tool Used | Precision Level |

|---|---|---|

| Rebound Testing | Leeb Tester | Moderate |

| Scratch Testing | Metal Files | Low |

While field tests provide immediate results, they should be complemented by formal lab tests for comprehensive verification.

Conducting Field Tests

Setting a systematic approach involves selecting random samples from batches. At each site, check these samples using the portable tester ensuring they comply with specified hardness ranges.

Achieving a balance between accuracy and practicality is vital for real-time quality assurance without disrupting operations.

Conclusion

Understanding excavator track roller composition and hardness provides security in demanding applications. Ensure quality by collaborating with transparent, reputable suppliers.

Footnotes

1. Explanation of alloy steels and their applications. ↩︎

2. Details on differential hardening processes. ↩︎

3. Overview of induction hardening benefits. ↩︎

4. Insight into induction hardening for surface hardness. ↩︎

5. Guide to hardness verification processes. ↩︎

6. Information on interpreting heat-treatment charts. ↩︎

7. Guide to using rebound hardness testers on-site. ↩︎