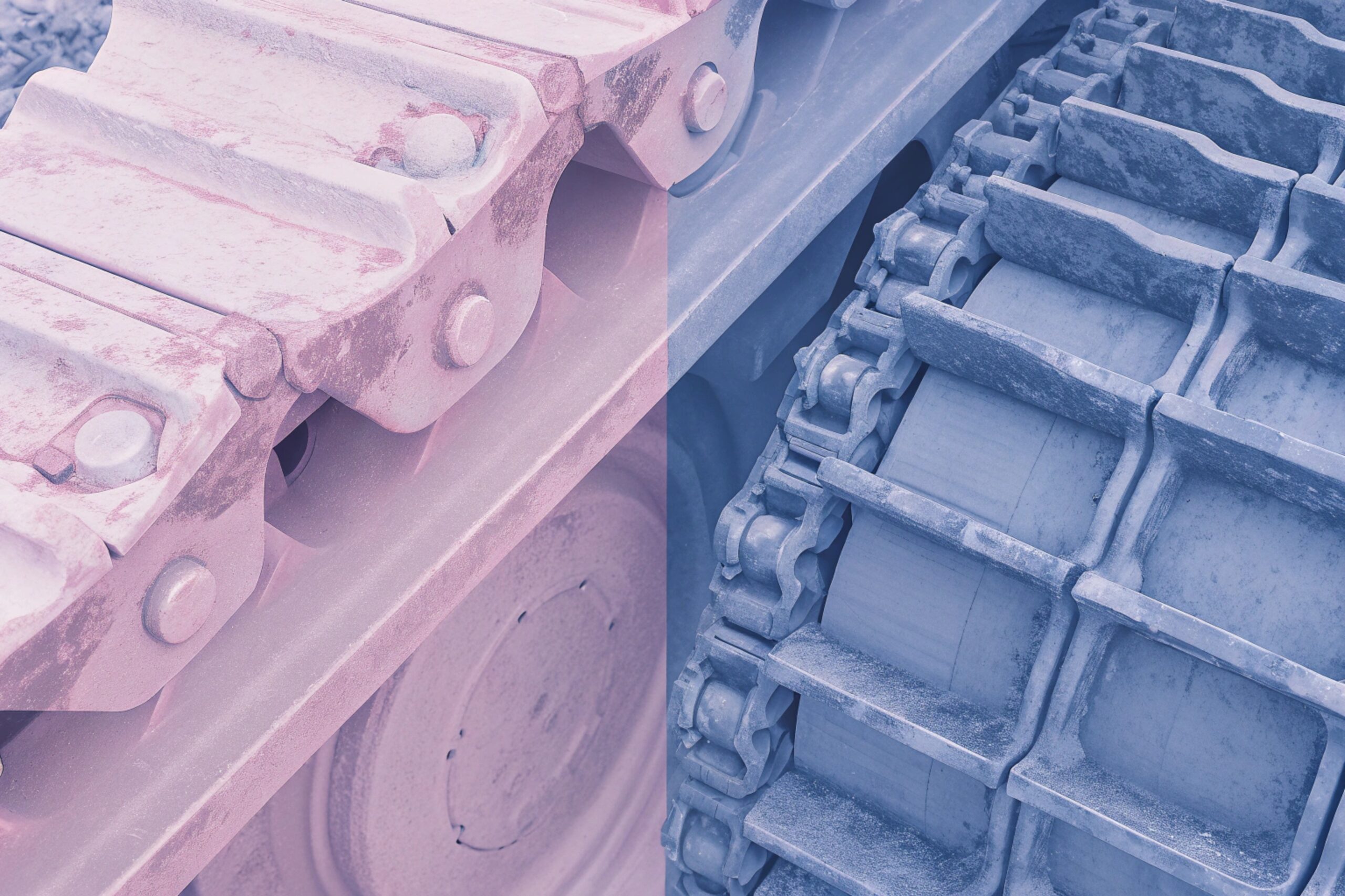

Undercarriage parts 1 are crucial for my excavator’s operation. Misalignments can cause inefficiencies and excessive wear. Understanding the sprocket tooth count and the flange bolt pattern 2 is key.

Ensuring compatibility between the sprocket tooth count and the flange bolt pattern with the excavator undercarriage is essential. The sprocket tooth count must align with the track links for smooth operation, while the flange bolt pattern should match the excavator’s drive hub to avoid installation issues. Adapting my machine’s components keeps it running smoothly. By ensuring all parts fit and work well together, I maximize performance and minimize breakdowns 3.

Where do I find my sprocket PCD and hole size?

Knowing my equipment inside and out is vital. If I overlook details, it can lead to significant machine downtime 4.

The Pitch Circle Diameter (PCD) and hole size can be found by consulting the machine’s specifications or measuring directly. Measuring PCD involves calculating the center-to-center distance between bolt holes and referencing a BCD chart.

It’s critical to accurately determine the PCD and hole size of my sprocket to ensure it matches my excavator’s final drive motor 5. BCD charts 6 help standardize these measurements, especially for varying models. To verify, I measure the central distance between two adjacent bolt holes and refer to a BCD chart. Each bolt’s diameter 7 also needs verification since inappropriate sizes can affect installation.

Understanding PCD and Hole Size

- PCD (Pitch Circle Diameter): It’s essential to align the rotation axis 8 with sprocket holes perfectly.

- Hole Size: Determines bolt compatibility, directly impacting the assembly.

- Measurement Tools: Utilize calipers or precision measuring tools 9 for accuracy.

Lack of attention can lead to incompatible installations and premature wear 10. The right sprocket ensures optimal performance, aligning correctly with the final drive assembly.

Does tooth count affect ground speed and wear on my machine?

Whenever my excavator doesn’t perform as expected, the tooth count could be an underlying problem I often encounter.

Yes, the tooth count directly influences ground speed and component wear. A mismatch between the sprocket’s tooth count and the track chain’s pitch can accelerate wear and impact the excavator’s speed and efficiency.

Adjusting the sprocket tooth count requires balancing torque and speed requirements. A higher tooth count results in lower torque but increased speed. Conversely, fewer teeth provide more torque at a reduced speed. So it’s essential to match the sprocket’s design closely with the intended machine function and track specifications.

Balancing Speed and Wear

Here’s how tooth count impacts your equipment:

- Ground Speed: More teeth = faster speed, fewer teeth = higher torque (slower speed).

- Wear Patterns: Correct count prevents uneven track or sprocket wear.

- Machine Compatibility: The right sprocket improves overall harmony of operations.

Optimal performance depends on this balance, ensuring productivity without unnecessary damage to components.

How do I check alignment with my final drive hub?

I’ve learned that overlooking alignment can cost time and efficiency. If parts aren’t properly aligned, performance suffers.

Check alignment by ensuring the flange bolt pattern’s size, shape, and orientation match the final drive hub. Proper alignment is crucial to prevent operational issues and avoid premature wear.

Alignment ensures the longevity of my machine components. Initially, I check all dimensions, then run a visual inspection to avoid misalignment-related inefficiencies and breakdowns. If everything appears intact, I proceed to test operations, listening for unusual noises or vibrations indicating potential misalignments needing correction.

Ensuring Proper Alignment

Components and dimensions to verify:

- Bolt Pattern Size: Matches hub dimensions.

- Shape and Orientation: Aligns perfectly with drive hub specifications.

- Operational Test: Quiet operation means perfect alignment.

Alignment ensures peak performance and avoids costly halts or repairs in productivity.

Can I upgrade to hardened teeth for longer service life?

I often wonder if my machinery can last longer with specific upgrades.

Yes, upgrading to hardened teeth can extend service life by improving durability and resistance to wear. Harder sprocket teeth withstand more stress and reduce the frequency of replacements and maintenance.

Considering upgrades, I explore the benefits of hardened teeth for their increased resistance to abrasive environments. Hardening treatments such as induction or flame hardening extend life significantly, minimizing downtime and enhancing performance. Integrating this upgrade requires ensuring compatibility with my equipment’s specs and consulting OEM standards.

The Benefits of Hardened Teeth

Why upgrade to hardened teeth:

- Durability: Withstands harsh conditions.

- Reduced Maintenance: Extends time between replacements.

- Cost-Effectiveness: Long-term savings on parts and labor.

By choosing hardened teeth, I not only optimize part lifetime but boost productivity and efficiency across operations.

Conclusion

Understanding sprocket specifications and making informed upgrades ensure my equipment stays efficient and minimizes downtime. This approach saves time and maintenance costs, boosting operational performance.

Footnotes

1. Overview of essential excavator undercarriage parts. ↩︎

2. Guide to measuring flange bolt patterns accurately. ↩︎

3. Strategies for heavy machinery preventative maintenance. ↩︎

4. Calculating the costs of machine downtime. ↩︎

5. How final drive motors work with sprockets. ↩︎

6. Using BCD (Bolt Circle Diameter) charts for measurements. ↩︎

7. Importance of correct bolt diameter in assembly. ↩︎

8. Techniques for aligning a sprocket’s rotation axis. ↩︎

9. Overview of precision measuring tools for mechanics. ↩︎

10. Common causes of premature wear in undercarriage parts. ↩︎