When ordering parts for excavators, one of the first things I think about is the quality assurance needed for high-risk applications 1. Material Test Certificates (MTCs) 2 are a must-have for verification.

Most reputable suppliers do offer Material Test Certificates (MTCs) and heat-treatment hardness curves to ensure their products meet standard quality requirements. For high-stakes environments, such as mining, having valid MTCs is essential for confirming that the parts can safely handle extreme conditions.

Buying undercarriage parts often entails asking suppliers to provide MTCs and documented heat-treatment hardness curves 3. These not only assess material quality 4 but also guarantee durability. However, the availability of such detailed data varies among suppliers.

What details must appear on a valid MTC for my parts?

A failure rate among my equipment means I need dependable documentation from suppliers. Missing or incorrect data increases the risk of part failure 5, affecting operations and safety.

A valid MTC should include the chemical composition, mechanical properties like tensile strength, yield strength, and compliance with relevant standards. Details such as the original material grade (e.g., 42CrMo) and heat numbers are critical when validating material specs against the order.

When evaluating MTCs, the critical factors include chemical analyses 6 and mechanical characteristics 7. The information in these documents establishes material reliability, aligning with contract specifications 8. Additionally, some prefer third-party verification 9 or testing by recognized labs like SGS for higher assurance.

Essential MTC Data

| Specification | Description |

|---|---|

| Chemical Composition | Breakdown of elements like C, Mn, Cr |

| Mechanical Properties | Tensile, yield strengths |

| Compliance Standards | According to standards like GB/T 3077-2015 |

How do I trace MTC heat numbers to delivered batches?

Any discrepancies between delivered and contracted parts prompt immediate assessment. Ensuring safe and compatible equipment is my goal when matching heat numbers to expected deliveries.

Tracing heat numbers involves cross-referencing documentation with delivery batch numbers. It’s imperative to have a system in place for quick verification. Ensuring parts adhere to stipulated quality requires managing and checking the MTC against batch-specific data.

Tracking heat numbers effectively requires an organized approach. This ensures parts delivered match contractual agreements. Managing a database for stored heat numbers related to the delivered products solidifies compliance and validates quality.

Heat Number Traceability

| Process | Action |

|---|---|

| Document Cross-referencing | Match MTC heat numbers with batch data |

| Database Management | Store heat numbers for verification |

| Quality Assurance Checks | Ensure consistency across deliveries |

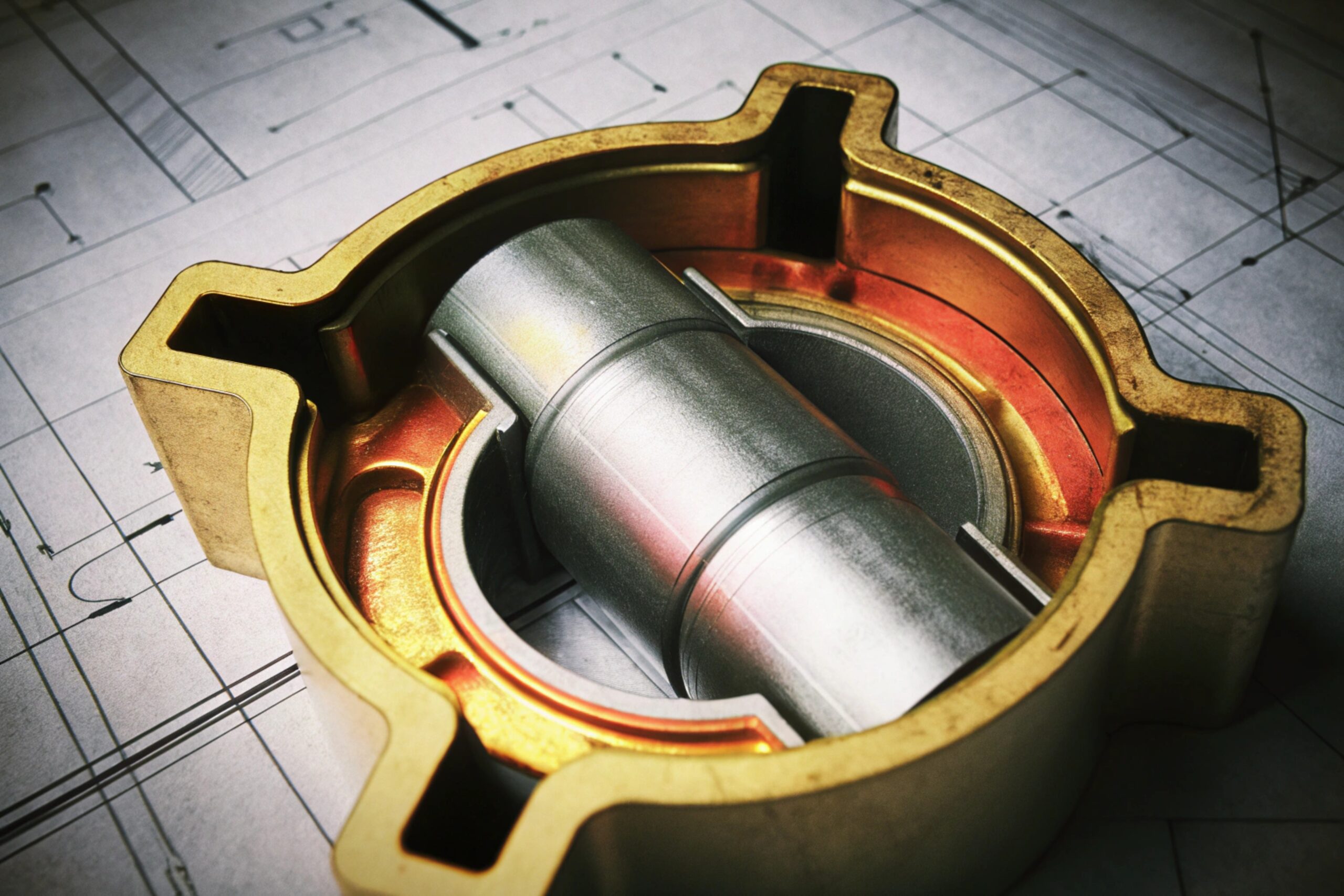

Can I get hardness mapping across critical surfaces?

When assessing parts for severe operational conditions, hardness mapping 10 becomes vital. Knowing the hardness distribution over surfaces helps in determining component resilience under stress.

Hardness mapping provides crucial insights into surface hardness distribution and its uniformity, important for parts subject to heavy loads. Hardening curves document the depth and consistency, aiding in evaluating critical components like pins and rollers.

The complexity of hardness mapping lies in obtaining consistent measurement gradients across surfaces. This ensures reliability in parts enduring excessive load and wear. Hardness distribution aids in performance evaluation under challenging conditions.

Hardness Mapping

| Component | Feature |

|---|---|

| Distribution | Uniformity of surface |

| Hardness Curve | Depth of hardening |

| Critical Surface Evaluation | Pin and roller focus |

Are 3.1 or 3.2 certificates available for my orders?

When considering international standards, certificates like 3.1 and 3.2 provide added validation. Negotiating supplier terms often involves ensuring these certifications are part of the assurance.

Certificates of compliance like 3.1 or 3.2 ensure parts meet stringent international guidelines for safety and reliability. These are often crucial for companies demanding additional proof beyond standard MTCs.

3.1 and 3.2 certificates serve as external verification, increasing trust in the supplier’s processes. Recognition from accredited bodies and ensuring certification availability solidifies product quality and conformity to safety standards.

Certificate Standards

| Certificate Type | Purpose |

|---|---|

| 3.1 Certification | Standard compliance assurance |

| 3.2 Certification | Third-party verification and approval |

Conclusion

Understanding MTCs and heat-treatment documentation enhances decision-making, ensuring parts meet quality criteria for durability and safety.

Footnotes

1. Overview of quality assurance protocols essential for high-risk industry applications. ↩︎

2. Learn what Material Test Certificates are and why they are critical for compliance. ↩︎

3. Guide to understanding heat-treatment curves for material durability. ↩︎

4. Methods for assessing and verifying the quality of industrial materials. ↩︎

5. Analysis of common causes and risks associated with component failure. ↩︎

6. Details on how chemical analysis impacts steel properties and validation. ↩︎

7. Defines key mechanical characteristics (tensile, yield) in metals. ↩︎

8. Importance of aligning procurement documentation with contract specifications. ↩︎

9. The role of third-party verification in supply chain management. ↩︎

10. Learn about the process of hardness mapping for critical surfaces. ↩︎