Achieving quality in excavator undercarriage parts 1 procurement often feels like navigating a complex maze. Frustrations stem from quality discrepancies, delivery delays, and inconsistent supplier support.

Understanding ISO9001 and SGS certifications can be pivotal. ISO9001 certification ensures quality management systems are in place, providing confidence in the consistent quality of your orders. An SGS inspection offers a thorough, third-party assessment of the parts, reinforcing reliability and compliance with specifications. These certifications foster trust in supplier performance and product quality, helping ensure smooth procurement processes.

Does ISO9001 Guarantee Consistent Quality in My Orders?

Encountering quality issues with excavator parts can quickly become a costly headache. With each order, comes the question: Will it meet the quality standards promised?

The ISO9001 certification provides a reliable indicator of quality consistency in orders. Manufacturers with this certification have well-established quality management systems that oversee every stage of production, helping avoid fluctuations in product quality. Regular audits ensure the adherence to these standards, enhancing trust in stable, repeatable procurement outcomes.

ISO9001 Certification Benefits

| Benefit | Description |

|---|---|

| Standardized Processes | Ensures all production steps are documented and controlled. |

| Continual Improvement | Focuses on improving processes and product quality over time. |

| Customer Satisfaction | Aims to enhance client satisfaction through consistent quality. |

A critical aspect of ISO9001 is its focus on documented processes 2 and continual improvement 3. A certified manufacturer ensures that every production step, from raw materials to finished products, aligns with these stringent processes. This structured approach minimizes the risks of receiving undercarriage parts that don’t meet expectations, reducing downtime and repair costs related to part failures. Moreover, ISO9001 certification encourages a culture centered on customer satisfaction and operational excellence 4. Certified suppliers are more proactive in resolving quality issues, reflecting their commitment to excellence. With this robust foundation, ISO9001 certification elevates product reliability, aligning supplier performance with your quality requirements.

What Does an SGS Inspection Cover Before Shipment?

How do uncertainties in part assessments impact your purchase decisions? It’s natural to question if what’s shipped really meets the promised specifications.

An SGS inspection encompasses a comprehensive evaluation of parts quality, ensuring they fulfill specific requirements before leaving the manufacturer’s premises. This third-party assessment includes laboratory analysis, dimensional verification, material compliance, and proper handling and packaging checks. Such reports enable informed decisions by verifying that parts align with contractual agreements and technical expectations.

Components of an SGS Inspection

| Component | Description |

|---|---|

| Laboratory Analysis | Independently tests material properties. |

| Dimensional Checks | Verifies precise measurements are as specified. |

| Handling & Packaging | Assesses conditions to ensure safe transport. |

SGS inspections delve deep into various facets of product quality. They verify materials used, ensuring that each component matches specified properties such as hardness, tensile strength 5, and durability. By evaluating these factors, SGS reports provide insights into how parts might perform in different operating conditions. Dimensional checks confirm the parts’ fit and functionality, eliminating the guesswork associated with their compatibility. Moreover, SGS assessments assess protective packaging practices 6, which can influence how parts withstand shipping and storage challenges. SGS’s neutral stance and rigorous testing methodologies offer a reliable layer of quality assurance, enabling buyers to maintain confidence in their procurement decisions.

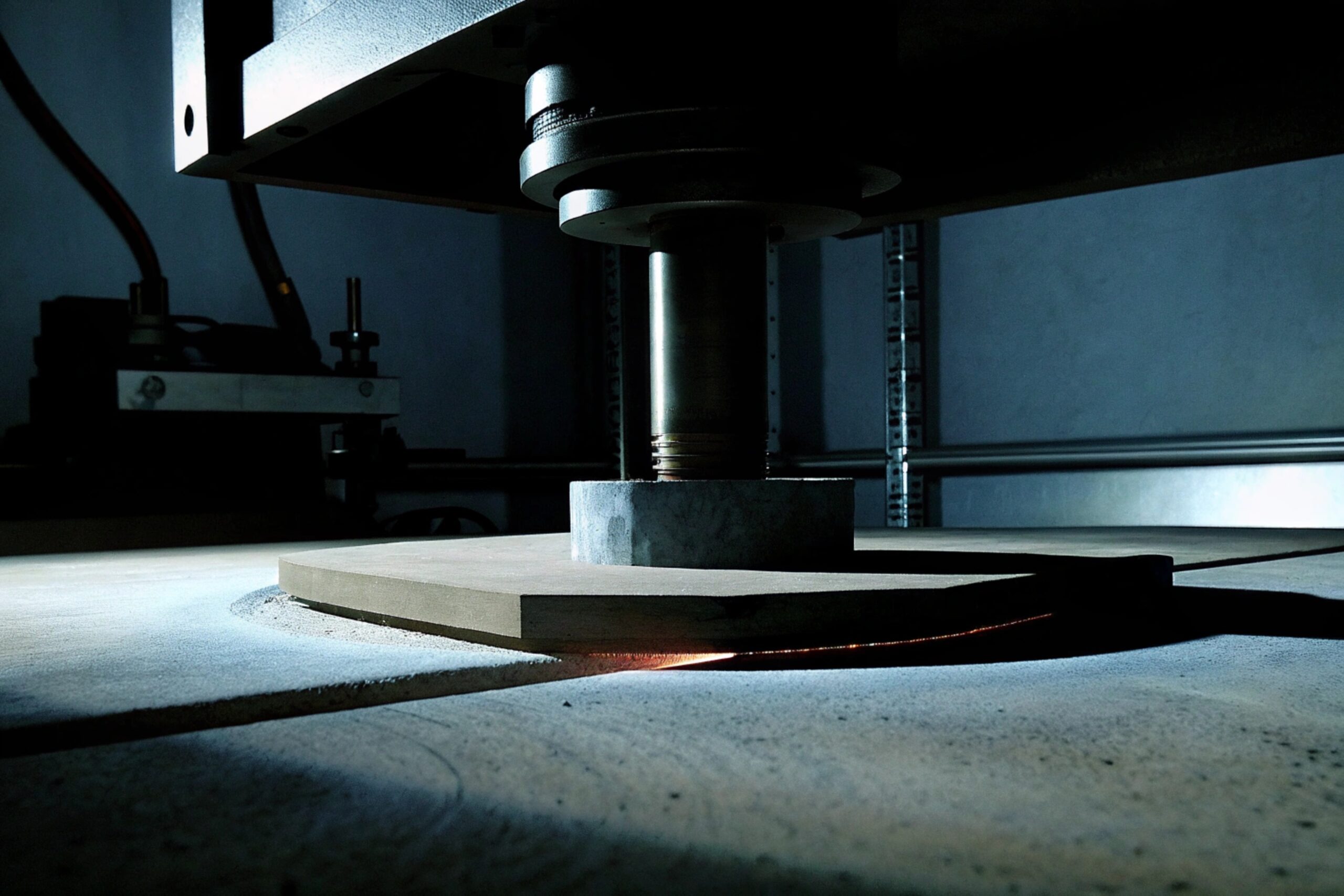

Should I Require Third-party Test Reports on Hardness?

Inadequate hardness in parts can severely impact machine performance and lifespan. But can relying on manufacturer-provided data alone be sufficient?

Requiring third-party test reports on hardness is a prudent strategy, giving additional validation of material properties beyond manufacturer assertions. These reports offer impartial data, reducing the risk of relying solely on internal assessments and providing a credible gauge of parts’ durability and performance.

Benefits of Third-party Hardness Testing

| Benefit | Explanation |

|---|---|

| Reduced Risk | Provides an unbiased evaluation of material attributes. |

| Accountability | Encourages suppliers to maintain high quality standards. |

| Verified Compliance | Ensures adherence to industry benchmarks for hardness. |

Hardness is a crucial attribute that influences wear resistance 7, load-bearing capacity, and overall structural integrity 8. Relying solely on supplier-conducted tests can leave gaps in assurance. Third-party tests are invaluable as they benchmark hardness against industry standards, ensuring accurate measurement of this key property. Reports from recognized laboratories also provide comparative data, facilitating informed decision-making by aligning parts’ hardness with operational demands. Additionally, third-party verification drives accountability in suppliers, encouraging them to adhere to quality benchmarks consistently. This strategy empowers buyers, ensuring that parts not only meet initial specifications but also sustain rigorous performance standards over extended usage, supporting long-term machine efficiency.

How Do I Verify a Supplier’s Certificate Authenticity?

With counterfeit certificates prevalent, ensuring their legitimacy can be challenging. What steps can prevent these risks?

Verifying a supplier’s certificate authenticity entails vigilant steps: cross-referencing with certifying bodies, examining document details, and assessing related records from reputed sources. Such measures safeguard procurement integrity and prevent reliance on counterfeit assurances.

Start by identifying the certifying organization 9 and verify the certificate’s issuance directly from them. Authentic certificates have unique identifiers that can be cross-checked with the documenting entity’s database. Engaging with professional networks or industry forums can further validate claims, as peer reviews often highlight credible sources. Next, assess certifications’ document features like date of issue, expiration, scope, and stamp authenticity. Certificate-based results or linked assessments, like test reports, should align with specific compliance standards 10 to substantiate claims. This layered evaluation approach assures one’s alignment with genuine suppliers who prioritize adherence to the highest quality and compliance standards.

Conclusion

ISO9001 and SGS certifications offer essential assurance of quality and compliance in excavator parts procurement. By validating supplier credentials and utilizing third-party validation, consistency and reliability in parts can be confidently achieved.

Footnotes

1. Overview of undercarriage components and their maintenance requirements. ↩︎

2. Learn why documentation is critical for quality management standards. ↩︎

3. Understanding the process of constant enhancement in manufacturing. ↩︎

4. Strategy for creating value and improving business consistency. ↩︎

5. Scientific definition regarding the resistance of material to breaking. ↩︎

6. Different methods used to protect goods during transit. ↩︎

7. Detailed explanation of how materials withstand damage from friction. ↩︎

8. Engineering concept ensuring a structure can support its load. ↩︎

9. Guide to valid accreditations and how certifications function. ↩︎

10. Importance of adhering to regulatory and internal business standards. ↩︎