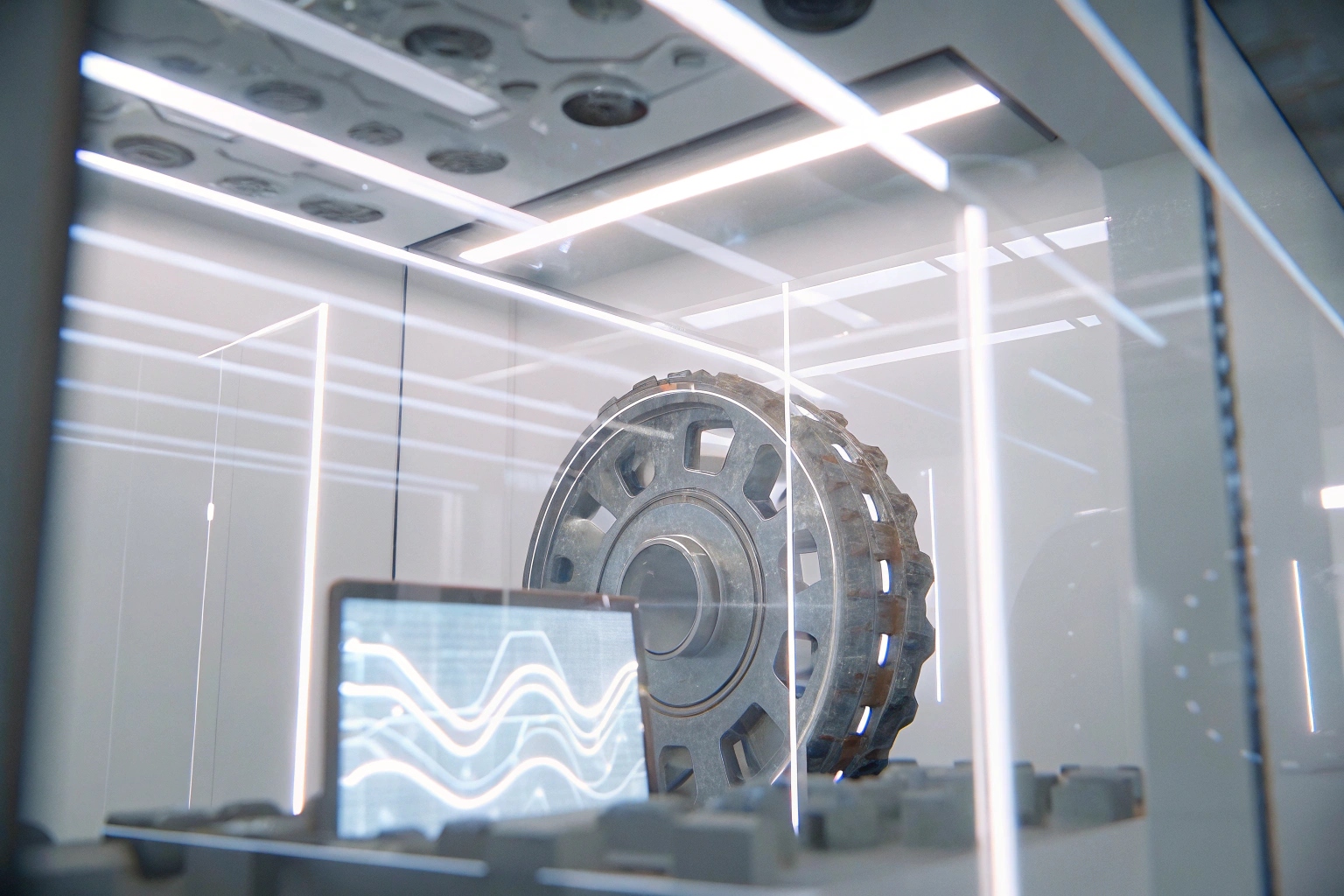

Surface treatments and coatings are essential for shielding excavator undercarriage parts 1 from corrosion, extending their lifespan and ensuring optimal performance. By creating protective barriers, treatments like phosphating 2, painting, and oxidation offer varying degrees of resistance against rust and wear.

Surface treatments and coatings improve excavator parts’ corrosion resistance by forming protective barriers. Phosphating creates crystalline layers that enhance paint adhesion while painting adds strong moisture and chemical barriers. Oxidation provides moderate protection, often supplemented by additional coatings.

These methods ensure that your excavator’s components withstand environmental elements, maintain structural integrity, and perform reliably across diverse work conditions.

Which coating suits marine or humid environments?

Painting is particularly suitable for humid or marine environments due to its strong protective capabilities. High-quality paints can create robust barriers, shielding metal surfaces from moisture and corrosive elements 3.

Marine and humid environments benefit from specialized coatings like epoxy paints, which provide superior chemical, moisture, and salt resistance. These coatings form effective barriers to protect excavator parts over extended periods.

Epoxy coatings 4 offer enhanced durability in wet and salty conditions. Their formulation helps prevent corrosion by minimizing exposure to external elements that typically lead to rust.

Benefits and Applications

Epoxy coatings are prevalent in environments with high humidity or exposure to saltwater. They are popular choices for protecting machinery in coastal or marine applications due to their protective qualities:

- Chemical Resistance: Epoxy coatings resist aggressive chemicals 5 present in marine environments.

- Moisture Blockage: These coatings prevent moisture penetration, thwarting rust formation.

- Extended Longevity: Enhanced resistance contributes to increased lifespan of machinery, reducing maintenance costs.

| Advantages of Epoxy Coatings | Applications |

|---|---|

| High chemical resistance | Coastal machinery |

| Moisture blockage | Marine equipment |

| Improved durability | Humid work sites |

Despite being effective, regular inspection and maintenance are necessary for epoxy coatings to preserve their protective effects in harsh conditions.

Can I request salt-spray test results for my parts?

Salt-spray tests 6 are crucial for assessing corrosion resistance of treatments and coatings on excavator parts. The results guide decisions about suitable coatings for specific applications.

Yes, requesting salt-spray test results is standard practice to evaluate corrosion resistance of coatings on excavator parts. These tests help compare different treatments and forecast long-term effectiveness under corrosive conditions.

Importance of Salt-Spray Tests

Salt-spray tests reveal how coatings perform when exposed to saline environments, simulating potential conditions parts may encounter:

- Benchmarking Performance: Comparing coatings helps identify the most effective solution for corrosion resistance.

- Quality Assurance: Results confirm the suitability of treatments for intended applications.

- Proactive Maintenance: Understanding longevity allows scheduling of maintenance and replacement plans 7.

| Salt-Spray Test Metrics | Interpretation |

|---|---|

| Corrosion time | Durability |

| Surface integrity | Adhesion quality |

Coatings with high salt-spray test performance are essential for marine, coastal, or humid environments to ensure longevity and reliability.

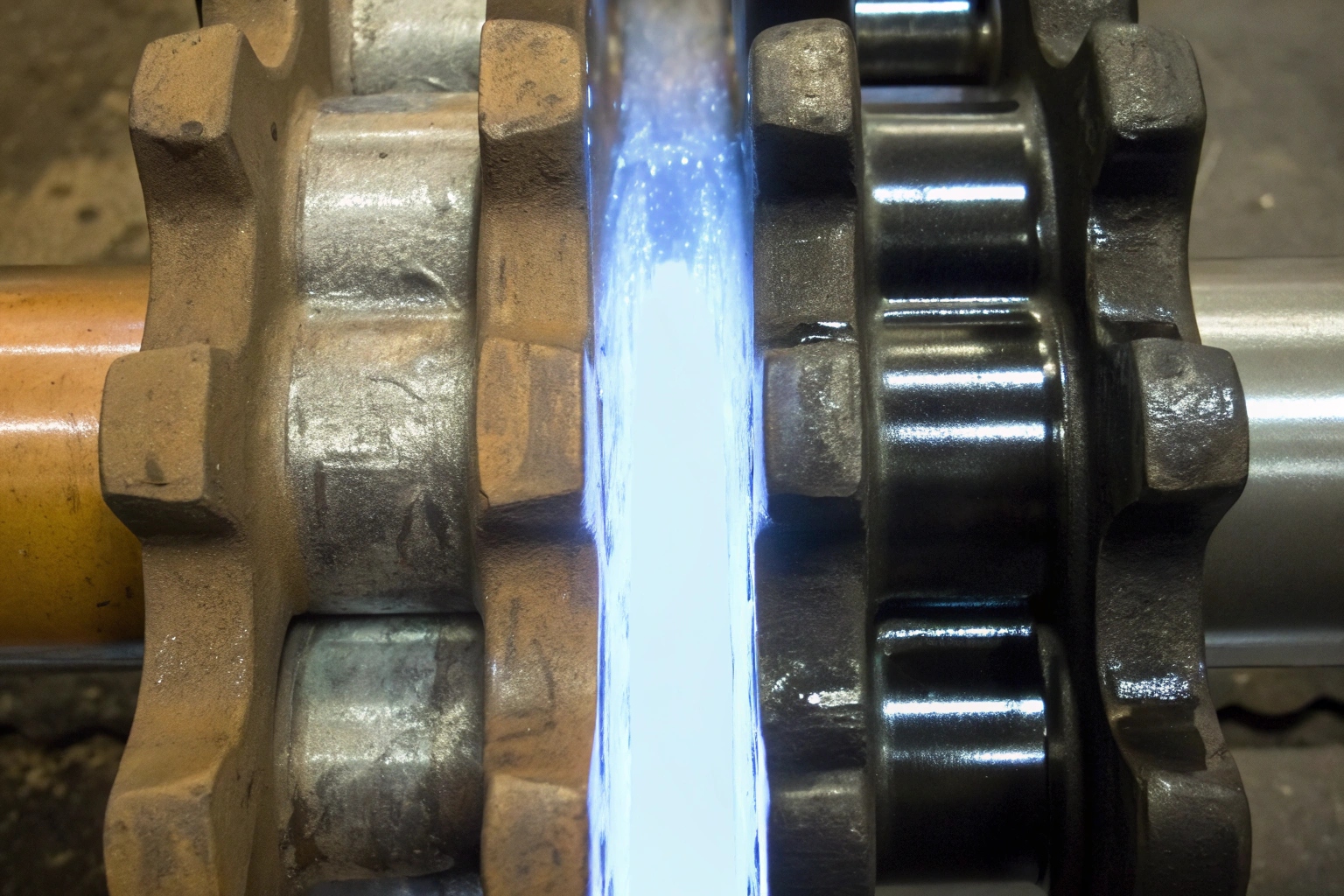

How does coating thickness affect dimensional fit?

Coating thickness directly influences dimensional fit 8, affecting the performance and assembly of excavator undercarriage parts. It’s crucial to account for this factor during selection.

Coating thickness impacts the dimensional fit by altering part dimensions slightly, potentially affecting both assembly and performance. It’s important to consider optimal thickness to ensure parts fit correctly while maintaining protective benefits.

Factors Influencing Dimensional Fit

The thickness of coatings can impact the overall size of components, which might lead to fitment issues during assembly:

- Dimension Changes: Thick coatings add extra material, possibly affecting tolerance levels 9.

- Performance Impact: Modifications in size can influence operational dynamics.

- Construction Challenges: Inaccurate thickness complicates installation and maintenance.

| Thickness Considerations | Effect on Fit |

|---|---|

| Layer thickness | Size adjustment |

| Tolerance management | Fit precision |

Selecting appropriate thickness levels requires balancing protective capabilities with precise fitting specifications to optimize functionality.

What prep and adhesion standards should I specify?

Specifying adhesion standards 10 optimizes coating performance, ensuring excavator parts resist corrosion effectively under harsh conditions.

Appropriate prep and adhesion standards are vital for maximizing coatings’ effectiveness against corrosion. Surface preparation, including cleaning and priming, ensures robust adhesion, extending the protective life of coatings.

Ensuring Effective Adhesion

Proper preparation is pivotal for ensuring coatings adhere well to surfaces, vital for optimal protective performance:

- Cleaning: Removing dirt, debris, and oils ensures base coat adherence.

- Priming: Layering primers enhances main coating adhesion, providing a stronger bond.

- Surface Smoothness: Smooth surfaces improve adhesion quality, preventing peeling or flaking.

| Prep Standards | Adhesion Outcomes |

|---|---|

| Thorough cleaning | Stronger bond |

| Effective priming | Extended lifespan |

Adhering to these standards boosts coating effectiveness, ensuring excavator parts maintain robust protection against corrosion in diverse environments.

Conclusion

Choosing the right surface treatments and coatings is essential for protecting excavator undercarriage parts from corrosion. Consider environmental conditions, coating types, and desired longevity when selecting options that optimize performance and durability.

Footnotes

1. Importance of undercarriage maintenance for heavy machinery. ↩︎

2. Overview of the phosphating process for metal protection. ↩︎

3. Understanding different types of environmental corrosion. ↩︎

4. Benefits of epoxy paints for industrial applications. ↩︎

5. How chemical resistance ratings extend equipment life. ↩︎

6. Guide to ISO standards for salt spray testing. ↩︎

7. Strategies for proactive equipment maintenance planning. ↩︎

8. Explanation of engineering fits and assembly tolerances. ↩︎

9. Guide to managing machining and coating tolerances. ↩︎

10. Standard methods for testing coating adhesion quality. ↩︎