The frustration of dealing with defective excavator undercarriage parts 1 can be overwhelming, potentially halting operations and causing financial loss. I’ve been there, facing unexpected repairs that drain resources. Seeking clarity on warranties is crucial for peace of mind.

A standard warranty for excavator undercarriage parts typically covers defects in materials 2 and workmanship for 6 to 12 months or 1,000 to 2,000 operating hours 3, whichever comes first. However, it excludes normal wear, misuse, and installation errors; these exclusions are common across suppliers. Understanding these specifics helps in making informed decisions and managing expectations effectively.

Transitioning to the specifics of warranty initiation and operating hour impact, let’s delve into how these elements affect your coverage.

Does My Warranty Start at Shipment or Installation?

Starting a warranty period can be mystifying. I once awaited parts, unsure of coverage commencement, which led to unexpected gaps in protection.

The initiation of your warranty often starts from the date of shipment, not the installation. This timing is crucial to account for potential delays and safeguard your machinery’s performance 4. It’s important to confirm with suppliers to avoid misunderstandings.

Many suppliers consider shipment as the starting point due to logistical challenges involved. Delivery times can vary, and suppliers generally want to ensure coverage during transit. Knowing this helps anticipate coverage gaps and plan installations promptly. Communication with suppliers can also refine these terms, potentially starting warranties upon installation, offering better alignment with operational readiness.

| Factor | Shipment Start | Installation Start |

|---|---|---|

| Common practice | Yes | No |

| Align with readiness | No | Yes |

| Avoid gaps | Risky | Better |

How Do Operating Hours Factor into My Warranty?

Pondering how hard-earned operating hours affect warranty claims is vital; I realized too late how quickly hours accumulate, cutting short my parts coverage.

Operating hours are fundamental in assessing warranty scope. Coverage is often expressed as “months or hours, whichever comes first.” This phrase is vital to understand, as surpassing the hour limit prematurely voids the warranty regardless of elapsed time.

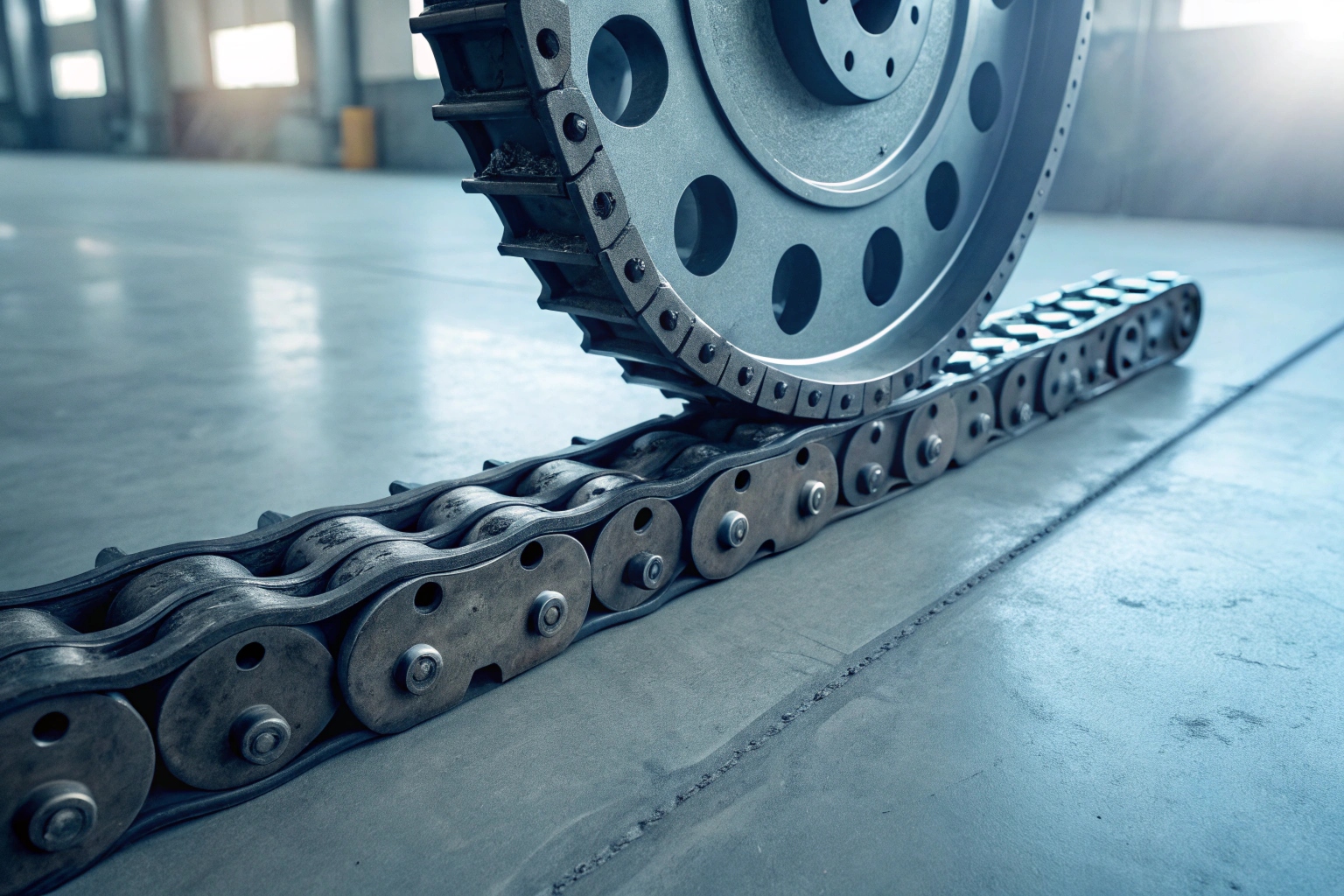

Operating hours limit warranties because they reflect actual use intensity, acting as a wear indicator 5. Components like rollers and idlers 6 endure stress proportional to active operation, justifying this metric. Consider assets’ usage patterns and opt for warranties in alignment with heavy-duty applications. Selecting parts from suppliers offering longer hour ranges may extend effective coverage, optimizing operational reliance.

| Warranty Type | Duration (Months) | Operating Hours |

|---|---|---|

| Standard | 6-12 | 1,000-2,000 |

| Heavy-Duty | 18-24 | 3,000 |

| Extended Warranty | 12+ | 2,000+ |

What Exclusions Commonly Apply to Wear Parts?

Navigating the world of exclusions was a game-changer for me; it highlighted unseen liabilities, protecting investments efficiently.

Common exclusions include expected wear and tear on items like track shoes 7, bushings, and sprocket teeth. Manufacturers anticipate these parts wearing with use, thus excluding them from warranty.

Exclusions often cover damage from improper installation or harsh environments. Mis-tensioned tracks or severe service scenarios, like mining, usually void warranties. Suppliers expect regular maintenance, such as adjusting track tension 8, to maintain coverage. Developing a comprehensive understanding of these exclusions encourages proactive care. Keep logs to satisfy warranty requirements, ensuring swift, valid claims. Such diligence offsets potential disputes, securing your investment further.

| Exclusion | Details |

|---|---|

| Normal Wear | Expected use-related degradation |

| Installation | Damage from improper fitting or adjustments |

| Harsh Use | Usage beyond standard conditions |

Can I Extend Warranty with Maintenance Plans?

Realizing maintenance could bolster warranty was an eye-opener; embracing this strategy mitigated unexpected repair costs for me.

Yes, extending warranties with maintenance plans is possible, often enhancing coverage duration and scope. Brands offer these plans to encourage regular upkeep, which aligns with maintenance schedules 9 and prolongs mechanical life.

Extended warranties typically come with stipulations, such as adhering strictly to maintenance schedules. This adherence is mutually beneficial, preventing wear issues leading to premature component failure 10. The plans may cover labor costs for repairs, so users benefit from reduced expenses and stress over unforeseen breakdowns. Investing in a maintenance plan signals commitment to upkeep, subtly reinforcing warranty agreements’ reliability.

| Maintenance Benefit | Warranty Impact |

|---|---|

| Scheduled upkeep | Extended coverage |

| Compliance | Validates warranty |

| Reduced repair costs | Financial relief |

Conclusion

Understanding excavator undercarriage part warranties helps manage expectations, optimize performance, and extend machinery longevity. A proactive approach to maintenance safeguards both investment and operations.

Footnotes

1. Comprehensive guide to excavator undercarriage components and maintenance. ↩︎

2. Legal definition and implications of material defects in warranties. ↩︎

3. Understanding the difference between calendar time and operating hours. ↩︎

4. Top tips for maintaining heavy equipment performance levels. ↩︎

5. Explanation of how wear indicators function on heavy machinery. ↩︎

6. Deep dive into undercarriage maintenance for rollers and idlers. ↩︎

7. Overview of track shoe types and their specific applications. ↩︎

8. Step-by-step instructions on adjusting excavator track tension. ↩︎

9. ISO standards regarding maintenance schedules for earth-moving machinery. ↩︎

10. Common causes and prevention of premature machinery failure. ↩︎