I hate seeing brand-new undercarriage parts arrive at a job site with deep scratches and chipped paint. It makes my team look unprofessional and invites rust before the machine even starts working.

To prevent coating damage when mixing multiple SKUs, you must isolate parts by weight and hardness, use protective interleaving materials like foam or plastic, and secure the load with air bags or strapping to stop all movement during transit.

I have spent years managing logistics for heavy machinery parts. I’ve learned that the secret to a perfect arrival is not just the paint quality, but how you manage the space inside the shipping container. If parts rub against each other for 40 days at sea, no paint in the world will survive. We have to be smarter about how we pack these heavy metal components.

Should I separate painted and bare-metal items?

I used to think that as long as everything was heavy steel, it didn’t matter where it sat in the crate. I was wrong, and I saw many "shiny metal" spots on my orders because of it.

You must separate painted and bare-metal items using physical barriers or different zones. Placing heavy, sharp bare-metal parts against painted surfaces causes deep gouges, leading to immediate oxidation and a poor professional appearance for the end user.

When we mix different SKUs, like a heavy track chain 1 and a smaller sprocket, we are dealing with different surface finishes. Some parts have thick protective paint, while others might only have a thin coat of oil. If these rub together during shipping, the bare metal acts like a file, grinding away the paint of the other part. This is why I always insist on a "Zone System" for our shipping containers.

Hardness and Weight Classification

One of the most effective ways to protect coatings is to organize the parts by their physical properties. In my experience, the heaviest items should always be the foundation. We use a simple table to train our loading staff on how to stack these mixed SKUs safely.

| Part Type | Weight Class | Surface Finish | Placement Strategy |

|---|---|---|---|

| Track Chains | Heavy | Painted/Coated | Bottom – Must be palletized |

| Idlers & Rollers | Medium | Painted | Middle – Secured with blocks |

| Sprockets | Medium | Bare or Painted | Middle – Separated by wood |

| Bolts & Pins | Light | Galvanized/Oiled | Top – Boxed or in buckets |

Preventing Contact Corrosion

Another reason to separate these items is to prevent galvanic corrosion 2. When different types of metal or different coating chemistries touch, moisture can cause a chemical reaction. This is very common in sea freight where humidity is high. By using plastic liners or wooden dividers, we create a "break" between the parts. This keeps the paint intact and prevents that ugly "rust bleed" that happens when bare metal touches a finished surface. I always tell my team: if it’s metal and it’s touching another metal, something is wrong with the packing.

What interleaving materials protect finishes?

I once received a shipment where the rollers looked like they had been in a rock tumbler because we didn’t use enough padding. Now, I never ship without specific interleaving materials.

The best materials to protect finishes include EPE foam sheets, heavy-duty bubble wrap, and corrugated cardboard dividers. These materials act as a cushion, absorbing the vibrations of the truck or ship and preventing the parts from rubbing against each other.

Using the right "stuffing" between parts is the cheapest insurance policy you can buy. In our factory in Fujian, we have tested different materials to see which ones hold up best under the weight of a 50kg track roller. Thin plastic film is useless; it tears in seconds. You need materials with "body" and "memory" that can be crushed but still provide a gap.

Top Protective Materials for Heavy Parts

Not all padding is created equal. When you are dealing with excavator parts, you need industrial-grade protection 3. Here is a list of what we use at Dingtai to ensure David Miller and our other clients receive perfect parts:

- EPE Foam (Pearl Cotton): This is my favorite. It is thick, waterproof, and doesn’t tear easily. We wrap it around the "shoulders" of rollers.

- VCI Plastic Film: This is a special film that prevents rust 4. It’s great for bare-metal areas like the internal bores of idlers.

- Heavy Cardboard: We use double-wall cardboard between flat surfaces. It is cheap and very effective at stopping paint scratches.

- Plywood Dividers: For the really heavy stuff, like track groups, we build small wooden walls inside the crate.

Why Soft Padding Isn’t Always Enough

Sometimes, soft padding isn’t enough because the weight of the parts is too high. If you put a 100kg part on a piece of bubble wrap, the bubbles pop instantly. In these cases, we use sacrificial wood 5. We place soft pine wood blocks between the metal parts. The metal bites into the wood, which holds the part in place and keeps the painted surfaces from touching. It’s a traditional method, but for heavy B2B shipments, it is still the most reliable way to prevent coating damage during a long ocean voyage.

Can I require corner protectors and foam wraps?

I found that most of the damage happens at the edges. A small bump on a corner can chip a large piece of paint, which is why I made corner protectors a standard requirement for all our OEM orders.

Yes, you should absolutely require corner protectors and foam wraps in your purchase agreement. These specific tools protect the most vulnerable points of the parts, ensuring that the factory finish remains intact during crane loading and forklift handling.

When David Miller orders from us, he expects the parts to look as good as they perform. If a sprocket arrives with the teeth chipped and the paint peeling, it reflects poorly on his brand. That is why we use hard plastic or heavy-duty cardboard corner protectors 6 on every pallet. It’s a small cost that saves thousands of dollars in potential claims and touch-up work.

Comparison of Edge Protection Methods

Different parts require different types of edge protection. I’ve put together a table to show which method works best for specific undercarriage components.

| Protection Type | Best For | Benefit |

|---|---|---|

| Hard Plastic Corners | Palletized Track Links | Prevents strapping from cutting the paint |

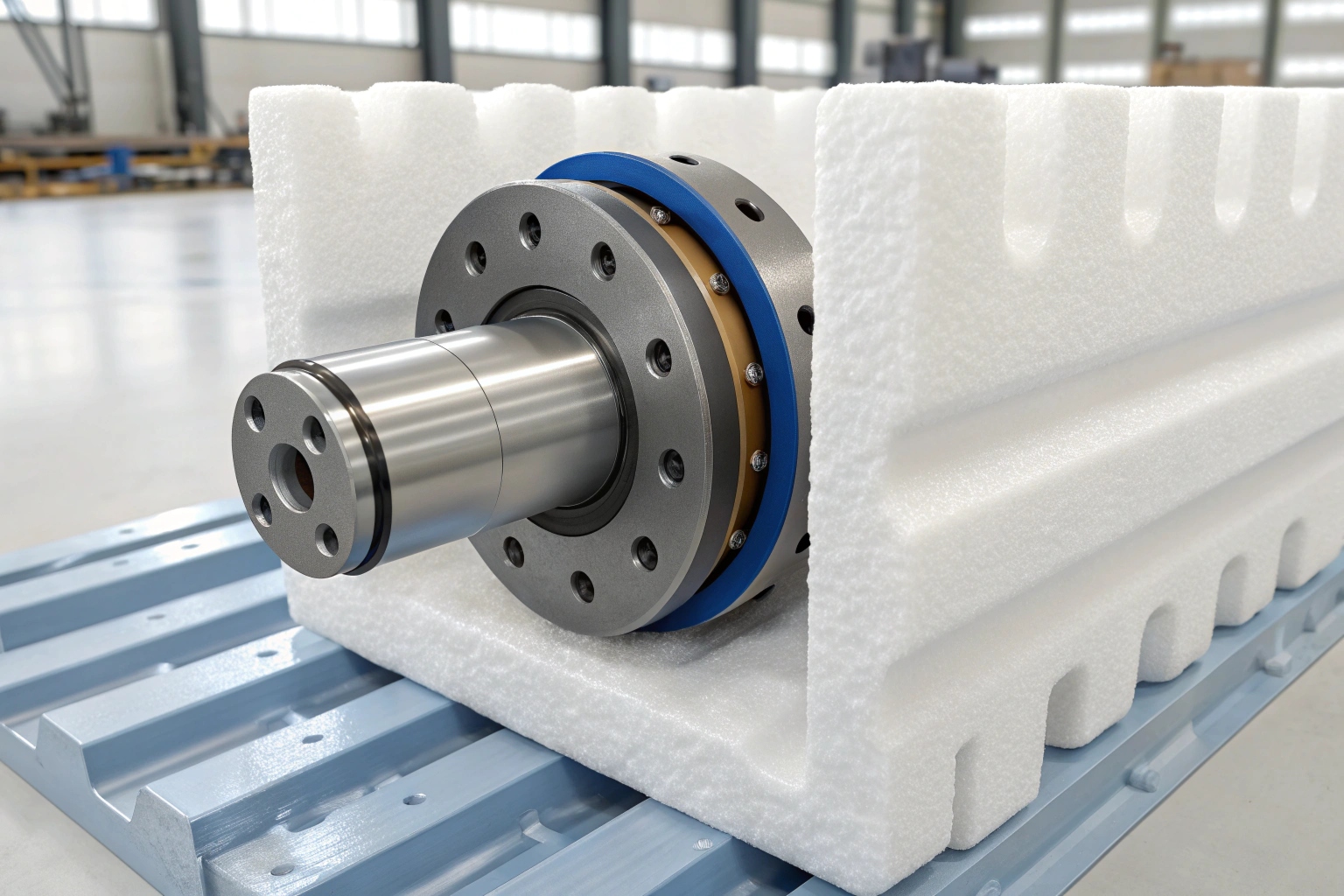

| Foam Tube Wraps | Roller Shafts | Protects the precision-ground surface |

| Cardboard Edge Boards | Crated Idlers | Distributes pressure across the crate wall |

| Rubber End Caps | Cylinder Rods / Pins | Prevents impact damage to the ends |

Negotiating Packaging in Your Contract

I always advise my clients to be very specific about packaging in their contracts. Don’t just say "standard export packing." That means different things to different people. Instead, write down: "All painted surfaces must be wrapped in 5mm EPE foam, and all pallet corners must have hard plastic protectors." When you are clear about your needs, a professional manufacturer like Dingtai will have no problem following the rules. It makes my job easier because I know exactly what the quality control team 7 needs to check before the container door closes.

How do I audit packaging quality on-site?

I have learned that you cannot just trust a "done" email; you have to see the evidence. Auditing the packaging is the final step in the quality control process.

To audit packaging quality, you should request a "Loading Photo Report" that shows the internal bracing, the use of interleaving materials, and the final container securing. Check for gaps between crates and ensure that heavy items are not stacked directly on top of delicate coatings.

I perform these audits personally for our key accounts. I look for "movement potential." If I can shake a part with my hand, it is not packed well enough. During the journey, the ship will tilt and the truck will hit bumps. If there is any space for a part to move, it will move, and that is when the coating gets destroyed.

The On-Site Audit Checklist

If you are auditing a supplier or checking your own warehouse, use this checklist. It’s the same one I use when I walk through our production facility in Fujian.

- Tightness Test: Are all parts tightly strapped? There should be no "clunking" sounds when the crate is moved.

- Moisture Protection: Is there a plastic liner 8 inside the wooden box? This prevents sea air from reaching the paint.

- Weight Distribution: Are the heaviest items on the bottom? This prevents "crush damage" to the coatings of the parts below.

- Separator Check: Is there a physical barrier (wood, foam, or cardboard) between every single metal part?

- Labeling: Are Fragile 9 or "This Side Up" signs clearly visible?

Using Technology for Remote Audits

Since most of my clients are in the USA or Europe, they can’t always be in China for the loading. I recommend using high-resolution video calls during the final packing stage. I often walk through the container with my phone, showing the customer exactly how we have blocked and braced the load. We also use Impact Indicators 10—small stickers that turn red if the crate is dropped or hit too hard. This creates a data-backed trail of accountability. If the parts arrive damaged, we can look at the indicator and know exactly when the handling went wrong.

Conclusion

Protecting coatings on mixed SKUs is all about isolation and immobilization. By using the right materials and a strict packing plan, you can ensure your parts arrive in perfect condition.

Footnotes

1. Professional community discussions on heavy equipment maintenance and track chain management. ↩︎

2. Technical resource explaining how dissimilar metals react and cause corrosion in humid environments. ↩︎

3. Leading supplier of industrial packaging materials used for heavy-duty surface protection. ↩︎

4. Guide to Volatile Corrosion Inhibitor (VCI) technology for long-term rust prevention. ↩︎

5. Resource on the structural properties of timber used in industrial bracing and packing. ↩︎

6. Industry insights on advanced packaging strategies for edge and corner protection. ↩︎

7. Global authority on quality control standards and auditing best practices. ↩︎

8. Information on protective barriers and liners used for moisture control in logistics. ↩︎

9. Best practices for labeling and handling high-value industrial freight. ↩︎

10. Specialized tools for monitoring impact and handling during international transit. ↩︎