I recently faced a major headache when a batch of track rollers failed prematurely on a client’s site, and I realized how much I needed a supplier who does more than just sell steel.

A professional excavator undercarriage parts supplier can perform structured failure analysis using tools like FTA or Fishbone diagrams. They provide formal corrective reports that identify root causes—such as material defects or improper heat treatment—and outline specific steps to prevent the problem from happening again in future batches.

Dealing with broken parts is frustrating, but getting a "we will check it" with no follow-up is worse, so I want to show you what a real technical partnership looks like.

How quickly can they deliver a root-cause report?

I know that when a machine is down in a mine or a construction site, every hour costs thousands of dollars, so a slow report is almost as bad as no report.

Most professional suppliers should provide an initial assessment within 48 hours of receiving photos and data, followed by a comprehensive root-cause report within 7 to 15 business days if physical lab testing is required.

When a failure happens, the clock starts ticking immediately. In my experience at Dingtai, we see that the speed of a report depends heavily on the "data chain." If you provide clear photos of the failure surface, the machine model, and the working hours, we can move much faster.

Why the timeline matters

A quick report is not just about being polite. It is about inventory management 1. If a specific batch of track chains has a pin-breaking issue, David Miller needs to know if he should stop selling the rest of that stock. A delay in the report means more machines might fail in the field.

Common Reporting Deadlines

| Phase | Action | Typical Timeline |

|---|---|---|

| Initial Review | Reviewing photos and site conditions | 1 – 2 Days |

| Physical Lab Test | Metallurgical and hardness testing | 3 – 5 Days |

| Analysis | Running Fishbone or FTA models | 2 – 3 Days |

| Final Report | Submission of corrective action plan | 1 Day |

Critical Thinking on Speed

You have to ask yourself: is the supplier just guessing, or are they measuring? Some suppliers give a fast answer just to keep you happy, saying it was "operator error" or "rocky ground." But a real report uses logic. If they don’t ask for the broken part back, or at least high-resolution macro photos of the grain structure, they probably aren’t doing a real root-cause analysis 2. They are just doing PR. We believe that a report without data is just an opinion.

Will they run metallography and microhardness tests?

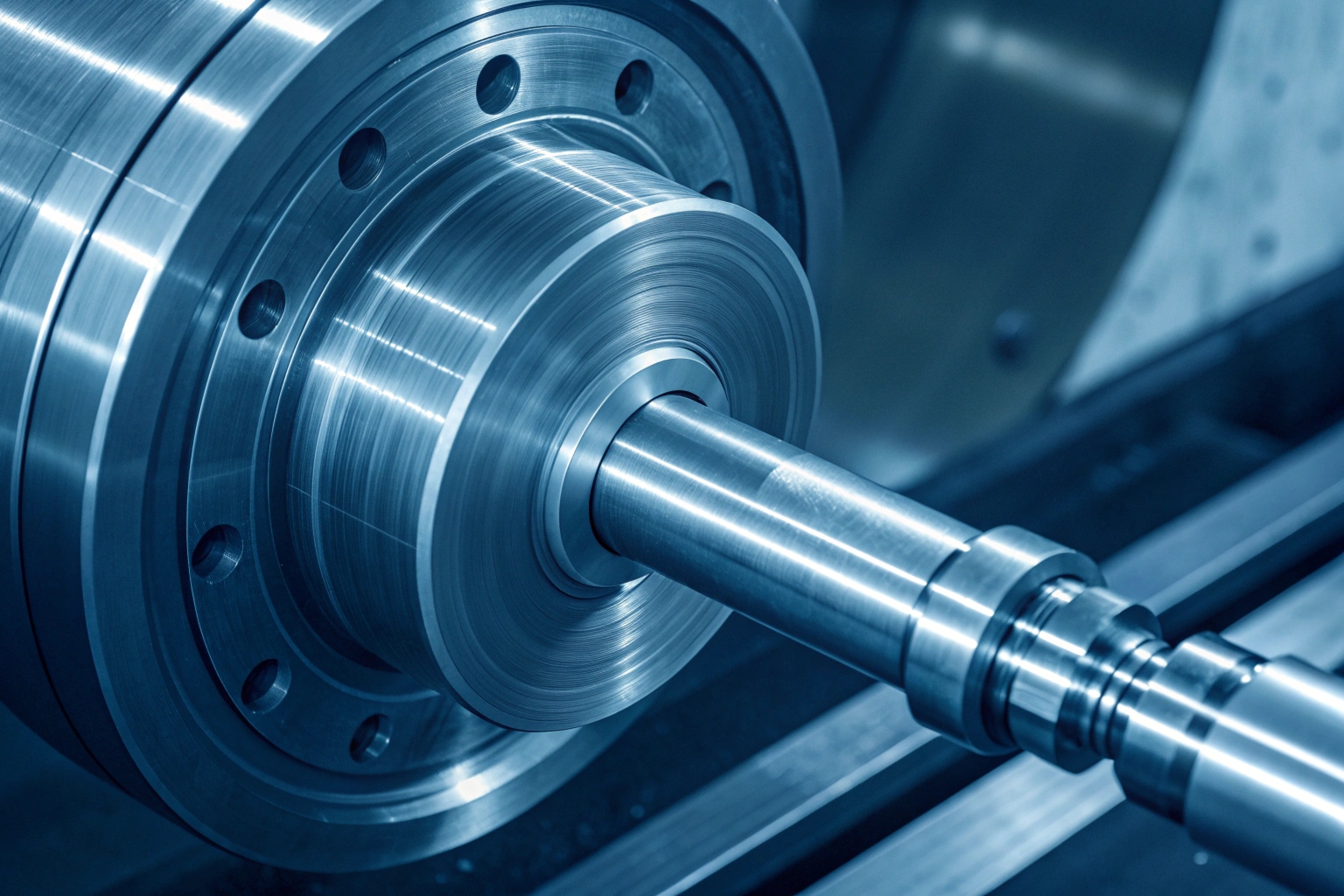

In our world of heavy steel, you can’t just look at a broken link and know why it snapped; you have to look inside the metal itself.

Reliable suppliers will perform metallography to check the grain structure and microhardness tests to verify the depth of the hardened layer, ensuring the part meets the exact OEM specifications for durability.

At our factory in Fujian, we use these tests as our "eyes." If a drive sprocket wears out too fast, we cut it open. We look for things like "decarburization" or an uneven "heat-affected zone." If the metal is too brittle, it will crack under impact; if it is too soft, it will wear down like butter.

Understanding the Tests

1. Metallographic Examination

This involves polishing a piece of the metal and looking at it under a high-power microscope. We look at the "pearlite" and "martensite" structures. If the cooling process 3 during heat treatment was wrong, the microscope will show it immediately. It’s like a DNA test for steel.

2. Microhardness Testing (Vickers or Rockwell)

We don’t just test the surface. We test at different depths. For a track roller, the surface must be very hard to resist wear, but the core must be tough to absorb shocks. If the hardness testing 4 shows the levels drop off too quickly as you go deeper into the metal, the part will fail long before its time.

Technical Comparison Table

| Feature | Standard Part | Premium (Dingtai) Part |

|---|---|---|

| Surface Hardness | 45-50 HRC | 52-58 HRC |

| Hardening Depth | 3mm – 5mm | 7mm – 10mm (Model dependent) |

| Material | Standard Carbon Steel | Boron Steel / 40Mn2 |

| Grain Size | Coarse (lower impact) | Fine (high impact resistance) |

Why this protects your brand

For a distributor like David, selling parts that fail is a disaster for his reputation. When a supplier provides a lab report 5 with actual photos of the metal’s grain, it gives the distributor the "ammo" he needs to talk to his customers. It shows that the manufacturer is scientific and honest. If a supplier says they "don’t have a lab," that is a huge red flag.

Can I review their CAPA implementation timeline?

I always tell my partners that a mistake is only a failure if you don’t learn from it, which is why a Corrective and Preventive Action (CAPA) plan is so vital.

You can and should review the CAPA timeline, which outlines when the manufacturer will change their process, such as adjusting quenching temperatures or switching steel suppliers, to ensure the defect is permanently removed.

A CAPA report isn’t just a piece of paper for ISO 9001 6 audits; it’s a promise. If we find that a batch of track groups failed because of a welding defect, the CAPA tells the customer exactly what we changed. Did we buy new welding robots 7? Did we increase the pre-heating time? When will the first "new and improved" parts ship?

The Steps of a Good CAPA

- Containment: What are we doing right now to stop more bad parts from shipping?

- Root Cause: Why did this happen? (The "5 Whys" method).

- Corrective Action: How do we fix the parts that are already made?

- Preventive Action: How do we change the factory system so it never happens again?

Sample CAPA Timeline

- Week 1: Stop production of the affected part number and quarantine warehouse stock.

- Week 2: Complete lab analysis and identify the specific heat treatment failure.

- Week 3: Update the PLC software on the induction hardening machines.

- Week 4: Run a pilot batch and perform 100% destructive testing.

- Week 5: Resume full production with new QC checkpoints.

Accountability in B2B

In the B2B world, transparency is everything. If a supplier hides their CAPA process, they are hiding their flaws. We prefer to show our customers the "before and after." If we had a problem, we own it, fix it, and show you the data that proves it’s fixed. This builds more trust than pretending to be perfect ever could.

I believe the best suppliers act as consultants, sharing knowledge from one failure to help you avoid ten more in the future.

Top-tier suppliers share "lessons learned" through technical bulletins or updated maintenance guides, helping you understand if a failure was due to manufacturing or if the machine’s operating environment requires a different part grade.

Sometimes, the "failure" isn’t a defect in the part, but a mismatch with the environment. If I see a customer’s track shoes bending in a high-impact rocky mine, I don’t just replace them with the same part. I share the lesson that they need heavy-duty equipment 8 shoes.

Knowledge Sharing Formats

- Technical Alerts: Brief emails explaining a new wear pattern we discovered.

- Installation Guides: Updated tips on how to properly tension a track to avoid link wear.

- Material Upgrades: Offering a "Heavy Duty" version of a part based on field failure data.

Digging into the Logic

Why do some suppliers stay silent? Usually, because they are afraid of liability. But in the long run, silence kills the business. If David Miller knows that a certain type of seal fails in extreme cold, and I tell him before he sells it to a customer in Alaska, I have saved his reputation.

Failure Analysis Methods

| Method | Purpose | Best For |

|---|---|---|

| Fishbone (Ishikawa) | Sorting causes into categories | Identifying if the issue is People, Machine, or Material. |

| Fault Tree Analysis 9 | Mapping how a system fails | Complex assemblies like recoil spring groups. |

| Wear Analysis 10 | Measuring metal loss over time | Predicting the remaining life of a set of chains. |

Sharing these lessons creates a "feedback loop." The factory gets better because the customer provides site data, and the customer gets better because the factory provides engineering insights. That is how a simple buy-sell relationship turns into a strategic partnership.

Conclusion

A professional supplier like Dingtai must provide full failure analysis, including FTA and metallography, to ensure quality consistency. These reports help distributors like David Miller minimize downtime and protect their brand reputation through clear CAPA timelines and shared technical lessons.

Footnotes

1. Overview of tracking and managing inventory to maintain business efficiency. ↩︎

2. Guide to identifying the underlying causes of problems in industrial systems. ↩︎

3. Technical explanation of how cooling rates affect the mechanical properties of steel. ↩︎

4. Detailed breakdown of Rockwell hardness testing procedures and its importance. ↩︎

5. Standard format and components required for a professional laboratory technical report. ↩︎

6. Official information on the international standard for quality management systems. ↩︎

7. Exploration of how automated welding robots improve consistency in manufacturing. ↩︎

8. Industry forum for discussing heavy machinery maintenance and operational challenges. ↩︎

9. Explanation of Fault Tree Analysis as a logic-based failure identification tool. ↩︎

10. Scientific methods used to analyze wear particles and predict equipment lifespan. ↩︎