I know the sinking feeling when a customer calls to complain about a broken track link. They claim it is a factory defect, but my engineers insist it is just rough usage. Managing these expectations is one of the hardest parts of our job in the heavy machinery aftermarket 1.

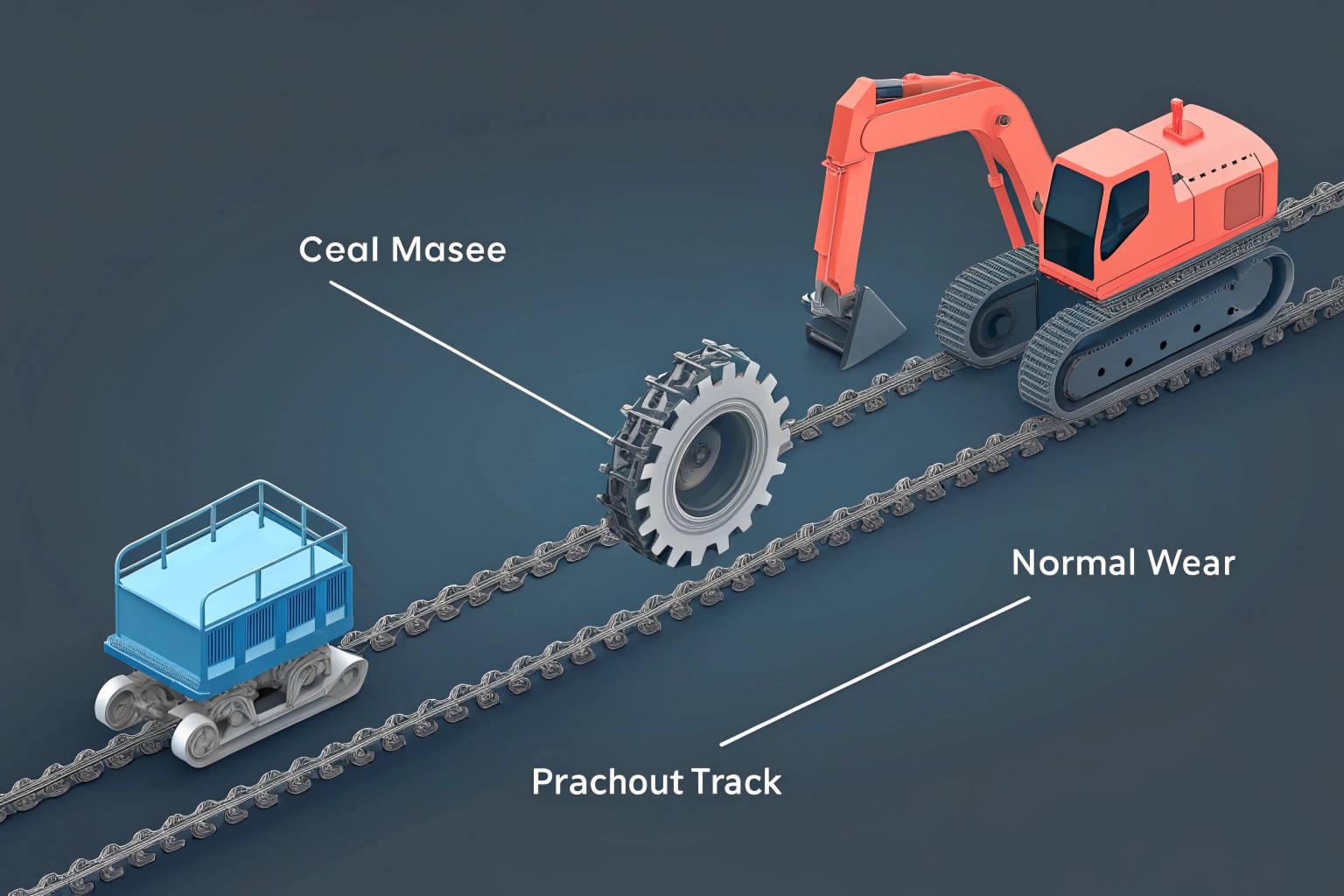

To reduce disputes, you must establish quantitative standards that separate predictable material loss from structural failure. Normal wear is gradual and uniform, adhering to the designed life cycle of the steel. Quality defects, however, appear as sudden cracks, asymmetric wear, or seal failures within the early "infant mortality" phase of the product.

We all want to avoid those long email chains where we argue over who pays for the shipping of a replacement part. To do this, we need to move away from opinions and start using data. We need to agree on what "bad" looks like before the parts even hit the dirt. In this article, I will share the specific criteria and frameworks I use at Dingtai to help my clients—from global OEMs to distributors like you—draw a clear line between a bad operator and a bad batch of steel.

What inspection criteria define abnormal wear?

When I walk through a scrap yard looking at old undercarriage parts, the metal tells a story. You just need to know the language to read it.

Abnormal wear is defined by its irregularity and timing. While normal wear reduces the dimension of a part evenly over time, abnormal wear shows up as flat spots, spalling (flaking metal), or deep gouges. If the hardness depth is breached prematurely, causing the wear rate to accelerate suddenly, this is a clear sign of a heat treatment failure.

To truly solve this, we need to look deeper than just the surface scratches. In my experience manufacturing chassis parts in Fujian, the difference between a claim we accept and one we reject often comes down to the microscopic structure 2 of the metal.

The Visual Language of Steel

First, let’s talk about spalling. If you see the metal flaking off the surface of a roller or a track link like the skin of an onion, that is usually a quality defect. It often means the heat treatment 3 was too aggressive, making the surface too brittle. However, if the surface is smooth but just worn down, that is friction doing its job.

Critical Dimensions

You cannot manage what you do not measure. A quality defect often presents itself as a dimension being "out of round." For example, on a bottom roller, if the wear is concentrated on only one side, it might look like a defect. But often, this is actually a sign of a bent frame on the excavator, which forces the roller to run at an angle.

We need to separate Material Failure from Mechanical Interference. Material failure is when the steel gives up (cracks, bubbles, soft spots). Mechanical interference is when outside forces destroy the steel.

Inspection Checklist for Defects vs. Wear

To make this practical for your warehouse team, I have created a comparison table. You can print this out and give it to your inspection engineers.

| Component | Normal Wear Signs (Customer Pays) | Quality Defect Signs (Manufacturer Pays) |

|---|---|---|

| Track Links | Even reduction in rail height; gradual elongation of pitch (stretch). | Cracks across the link body; breakage at the pin boss; sudden snapping under load. |

| Rollers | Uniform wear across the tread; gradual reduction in flange height. | Oil leakage within first 200 hours; seizure (won’t spin); vertical cracks in the shell. |

| Sprockets | Teeth become sharp or pointed; wear on the drive side of the tooth. | Teeth breaking off at the base; cracks radiating from the bolt holes. |

| Idlers | Wear on the center rib; slight side wear from turning. | Cracks in the welding seams; brackets breaking; internal seal failure causing oil loss. |

| Track Shoes | Grouser bars worn down evenly; rounded corners. | Plate bending under standard load; grouser bars snapping off cleanly (bad casting). |

The Role of Hardness Testing

If you really want to stop disputes, buy a portable hardness tester. It is a small investment. When a customer claims a part wore out in 500 hours, test the Rockwell C hardness 4 (HRC).

- If the HRC is low (e.g., below 50), it is a manufacturing defect (bad heat treatment).

- If the HRC is correct (e.g., 52-56) but the part is worn, it is abrasive conditions.

This single data point ends 90% of arguments instantly.

Should I set hour-based thresholds per part?

Time is money, but in our industry, "hours" are a vague unit of measurement. A thousand hours of work means very different things depending on the job site.

You should set hour-based thresholds, but they must be tiered based on the application. A generic "2000-hour warranty" is a trap. Instead, define an "Early Failure Period" (e.g., 0-500 hours) where almost all failures are treated as defects, and a "Wear-Out Period" where claims require proof of material failure.

I have seen many contracts fail because they were too simple. They stated "1-year warranty" without defining the hours. A machine in a mining site runs 20 hours a day; a machine on a farm runs 20 hours a week.

The Bathtub Curve of Reliability

In engineering, we use something called the Bathtub Curve 5. It describes failure rates over time.

- Infant Mortality (0 – 500 Hours): If a roller leaks or a link snaps here, it is almost certainly my fault as the manufacturer. It means there was an assembly error, a bad seal, or a casting void. We replace these immediately, no questions asked.

- Constant Failure Rate (500 – 3000 Hours): This is the random zone. Failures here are rare. If they happen, we need to investigate. Was it a rock impact? Was it lack of grease?

- Wear-Out Zone (3000+ Hours): This is where parts naturally die. Claims here are usually rejected unless there is clear evidence of a hidden defect that took years to surface.

Setting Realistic Benchmarks

You need to set expectations with your customers based on the class of the machine. A 20-ton excavator has different stress limits than a 50-ton bulldozer.

Here is a guide on how we categorize expected lifespan for our Dingtai products under "Standard Earthmoving" conditions. You can use this to set your warranty terms.

Benchmarking Table

| Part Category | Early Failure Threshold (Defect Likely) | Expected Normal Lifespan (Standard Soil) |

|---|---|---|

| Track Chains (Lubricated) | < 500 Hours | 4,000 – 6,000 Hours |

| Bottom Rollers | < 300 Hours (usually leaks) | 3,500 – 5,000 Hours |

| Drive Sprockets | < 500 Hours (breakage) | 3,000 – 4,500 Hours |

| Idlers | < 500 Hours (seals/brackets) | 4,000 – 6,000 Hours |

The "Pro-Rata" Approach

To make this fair, I often suggest a pro-rata warranty 6 for the middle period.

- If a track chain breaks at 100 hours: 100% Credit.

- If it breaks at 1,500 hours (and expected life is 3,000): 50% Credit.

This approach acknowledges that the customer got some value from the product. It reduces the "all or nothing" tension in negotiations. It shows your customer that you are reasonable, but you also protect your margins.

Can we use field photos as evidence standards?

I cannot fly to Texas or Toronto every time a track shoe breaks. We rely on eyes on the ground.

Field photos are the gold standard for evidence, but only if they follow a strict protocol. A blurry photo of a muddy part is useless. We need clear shots of the fracture surface, the production ID code, and the overall machine condition to contextualize the failure.

In my years of dealing with international claims, I reject about 40% of them simply because the evidence is insufficient. It is not that I do not trust the client; it is that I cannot prove the root cause to my own quality control team without clear data.

The "Clean and Clear" Rule

The biggest mistake is taking photos of parts covered in mud and grease.

- Step 1: Clean the part. We need to see the metal, not the dirt.

- Step 2: Find the Casting/Stamping Number. Every reputable manufacturer (including us) stamps a batch code on the part. This traces back to the production date and raw material batch. No code, no claim.

- Step 3: Use a scale. Put a tape measure or a coin next to the crack or wear spot. This gives us perspective on size.

Interpreting Fracture Surfaces

Photos of how a part broke tell us everything.

- Brittle Fracture: The break looks granular and flat, like a broken biscuit. This usually means the metal was too hard or the casting had impurities (Defect).

- Ductile Fracture: The metal looks stretched or twisted before it snapped. This means the metal was tough, but the load was simply too heavy (Overload/Abuse).

- Fatigue Cracks: You see "beach marks" (concentric lines) starting from a small point and growing. This means the crack started a long time ago and grew slowly. If this starts from a welding pore, it is a defect.

The Evidence Package

When you submit a claim to a factory in China, or when your customer submits one to you, require this standard package. If they cannot provide it, the claim is pending.

Required Evidence Table

| Photo Type | Purpose | What to Look For |

|---|---|---|

| Overview Shot | Context | The entire machine. Is it buried in a swamp? Is it on rock? |

| ID Shot | Traceability | The Part Number and Batch Code stamped on the metal. |

| The Failure | Analysis | Close up of the fracture surface 7. Macro mode is essential here. |

| The Hour Meter | Verification | A photo of the cabin dashboard showing total machine hours. |

| The Track Tension | Maintenance | A photo showing the sag of the track. Overtight tracks cause 50% of failures. |

By standardizing this, you signal to your customers that you are professional. You are not trying to dodge the claim; you are trying to analyze it scientifically. This builds trust.

Do operating conditions modify acceptance limits?

You cannot judge a fish by its ability to climb a tree, and you cannot judge a standard track chain by its performance in a granite quarry.

Operating conditions absolutely dictate the acceptance limits. Soil abrasiveness, impact levels, and moisture content drastically change the wear rate. You must categorize your customers’ working environments and adjust the warranty terms to match the reality of their job sites.

I once had a client in Australia whose sprockets were wearing out in 800 hours. He was furious. When we finally got photos of the site, we saw he was working in silica sand 8 mixed with saltwater. That is essentially grinding paste. The parts weren’t defective; they were just being eaten alive.

The Three Main Enemies of Undercarriage

We need to educate the end-user that the warranty covers the steel, not the environment.

- Impact (Rock/Demolition):

- Risk: Cracking and breakage.

- Adjustment: In these conditions, we accept claims for internal casting flaws but we usually reject claims for bent shoes or chipped rollers. High impact requires heavy-duty (HD) parts. If they use standard parts in a quarry, the warranty is void.

- Abrasion (Sand/Gravel):

- Risk: Rapid material loss.

- Adjustment: We shorten the wear-life expectation by 50%. A roller that lasts 4,000 hours in clay might only last 2,000 hours in sand. This is not a defect. We focus on checking the hardness here. If the hardness is good, the wear is normal.

- Corrosion (Swamp/Peat/Salt):

- Risk: Seized pins and seal failures.

- Adjustment: Packing caused by mud drying on the tracks increases tension. This destroys seals. We check if the customer cleans their undercarriage daily. If the undercarriage is packed solid with dry mud in the photos, the claim for leaking seals is invalid.

Customizing the Solution

This is where my role as a manufacturer helps you. If you know your customer is in a high-abrasion zone, do not sell them the standard material.

- Standard Duty: 40MnB material. Good for general construction.

- Heavy Duty (Mining): 35MnB with deeper induction hardening 9.

- Extreme Duty: Special alloy steels with higher Chromium content 10 for wear resistance.

Soil Factor Adjustment Table

When evaluating a claim, apply a "Soil Factor" to the expected hours.

| Operating Condition | Soil Factor | Calculation Example |

|---|---|---|

| Clay / Soft Earth | 1.0 (Baseline) | Expect 4,000 Hours. |

| Gravel / Common Earth | 0.7 | Expect 2,800 Hours (4000 x 0.7). |

| Sand / Abrasive Material | 0.5 | Expect 2,000 Hours. |

| Blasted Rock / Quarry | 0.4 | Expect 1,600 Hours. |

If a customer in a quarry complains that a part lasted 1,800 hours, and your baseline is 4,000, you can show them this logic. They actually got good life out of the part considering the Soil Factor. This shifts the conversation from "Your part is bad" to "Your job is tough."

Conclusion

Distinguishing between normal wear and quality defects is about removing emotion and using logic. By establishing clear wear limits, setting hour thresholds based on working conditions, and demanding standardized photographic evidence, you protect your business from unfair claims. Remember, a good supplier does not just sell you parts; we help you build the technical criteria to defend your profits.

Footnotes

1. Market analysis of the global construction equipment aftermarket. ↩︎

2. Guide to understanding metal structures through metallography. ↩︎

3. Explanation of heat treatment processes for altering metal properties. ↩︎

4. Standard test method for measuring the hardness of metallic materials. ↩︎

5. Engineering concept describing product failure rates over time. ↩︎

6. Definition of warranty coverage proportional to remaining product life. ↩︎

7. Scientific analysis of surface features to determine failure modes. ↩︎

8. Properties of silica and its role in abrasive wear. ↩︎

9. Surface hardening process using electromagnetic induction. ↩︎

10. Benefits of chromium in steel for corrosion and wear resistance. ↩︎