I see too many high-quality parts fail simply because of bad installation practices. It hurts your reputation and wastes your money. Let me explain how the right supplier support stops this from happening to you.

Yes, reliable suppliers often provide installation training materials for excavator undercarriage parts. This includes digital manuals, step-by-step videos, and torque specifications. However, the depth of this support varies, so you must confirm these resources are available before placing your order.

It is not enough to just buy a steel part; you are buying the performance of that part. When you source undercarriage components from overseas, you might worry about the gap in technical knowledge. You might wonder if your team or your customers will know exactly how to fit a new track group 1 or replace a drive tumbler without damaging the machine. A partner, not just a seller, bridges this gap. They provide the knowledge you need to ensure the product lasts as long as it should.

Do they offer torque charts and tensioning guides?

I hate seeing clients struggle with loose tracks or snapped bolts because of guesswork. Precision is the only way to ensure safety and longevity for your heavy equipment.

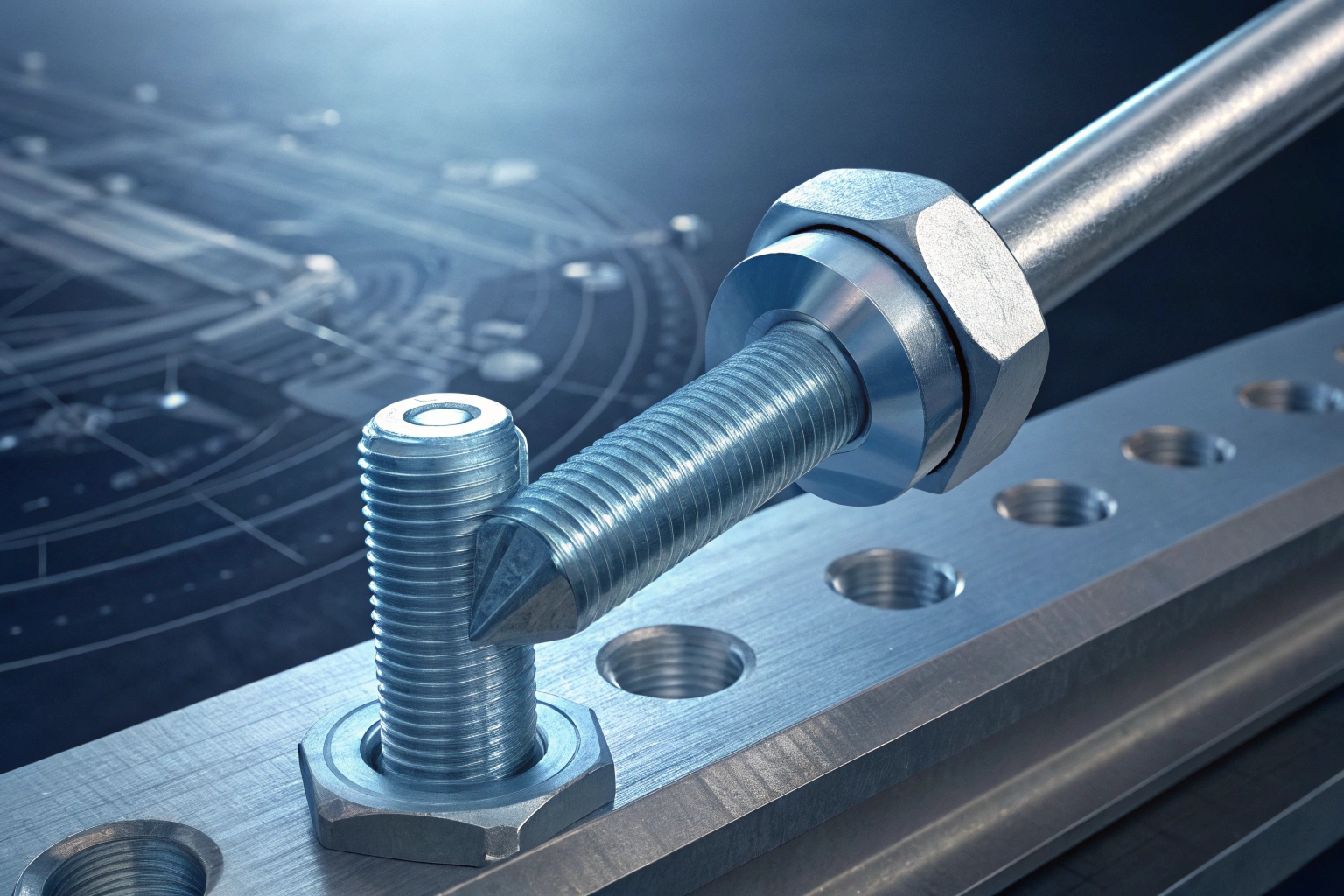

Top-tier manufacturers always provide specific torque charts and tensioning guides. These documents list the exact force needed for track bolts and proper sag measurements. Without them, your technicians are guessing, which leads to immediate mechanical failures.

When we talk about the life of an undercarriage, the installation phase is critical. Many people think that once they buy a heavy-duty track chain or a robust roller, the job is done. But I have seen premium parts fail in a few weeks because they were not installed correctly. The most common issue is improper torque on the bolts.

If a technician does not have a clear chart, they might under-tighten a bolt. This causes the track shoe 2 to loosen during operation. The movement wears out the bolt holes, and eventually, the shoe falls off. On the other hand, if they over-tighten the bolt, it stretches the metal. When the machine hits a rock, that stretched bolt snaps instantly. This is why a simple piece of paper—the torque chart—is as valuable as the steel itself.

A good supplier should provide data that matches the specific material grade of the bolts they sell. A Grade 10.9 bolt needs different force than a Grade 12.9 bolt 3. You should expect your supplier to provide a clear, easy-to-read table. It should not be a generic list copied from the internet. It must come from their quality control department.

why tensioning guides matter

Beyond bolts, track tension 4 is vital. Every excavator model has a "sweet spot" for track sag. If the track is too tight, it puts massive stress on the bushings and the final drive 5. It burns more fuel and wears out the internal pins quickly. If it is too loose, the track can de-track (come off) while the operator is working on a slope. This is dangerous and causes downtime.

Your supplier should give you a guide on how to measure this. It usually involves lifting the machine and measuring the distance from the bottom of the frame to the track shoe.

Here is a comparison of what you might get from different types of suppliers:

| Feature | Generic Trader | Professional Manufacturer |

|---|---|---|

| Torque Specs | General "standard" numbers | Exact values based on steel grade |

| Tension Data | None or verbal advice | Model-specific sag limits |

| Format | Email text | PDF or printed manual |

| Update Frequency | Never | Updated with product changes |

You should asking for these documents before you pay the deposit. It shows the supplier that you are serious about quality. It also tests their technical ability. If they cannot give you a torque chart, they probably do not know much about what they are manufacturing.

Can I get multi-language training content?

Your team might speak Spanish, French, or other languages, and English-only manuals cause mistakes. I believe safety instructions must be understood by everyone on the floor.

Global suppliers understand that your workforce is diverse. Many now offer training content in multiple languages, including English, Spanish, and French. This ensures every technician understands safety protocols and installation steps, regardless of their native language.

In the construction industry, the workforce is international. I often speak with buyers in the US who have technicians from Mexico, or buyers in Europe with teams from all over the continent. If I send a manual that is only in English (or worse, only in Chinese), I am not helping them. I am creating a barrier.

A responsible manufacturer will invest in translating their core documents. This includes the installation manuals, the safety warnings, and the troubleshooting guides. We usually provide a bilingual format. For example, the left column is English, and the right column is Spanish. This allows a supervisor and a technician to look at the same page and understand each other.

The power of visual aids

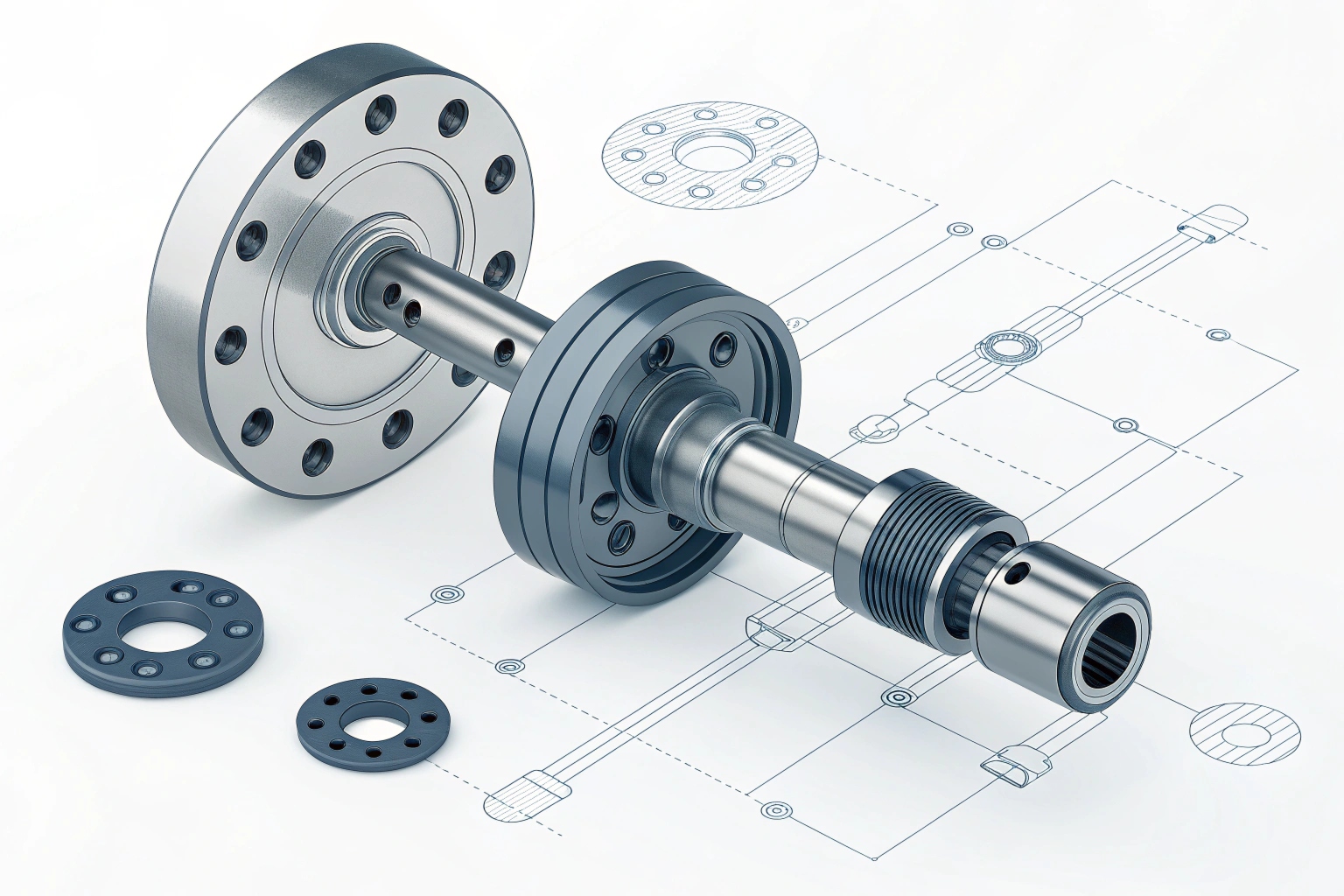

However, text is not the only way to communicate. The best "language" for mechanical parts is a good diagram. We focus heavily on Exploded Views 6. An exploded view shows every single washer, seal, and bolt as if the part has been pulled apart.

You do not need to read a specific language to understand an exploded view. You can see the order of assembly. You can see which direction the seal faces. You can see where the grease fitting goes. These visual aids are critical for complex assemblies like track adjusters or tensioning cylinders.

We also use color-coding in our diagrams. Red might mean "apply grease," blue might mean "apply thread locker," and yellow might mean "check clearance." This visual system reduces errors significantly.

What to ask your supplier

When you are negotiating a contract, ask if they have a library of these documents. You can request a sample. If they only have Chinese documents, it will cost you time and money to translate them yourself. A supplier who wants your business long-term will have these ready for you.

| Document Type | Best Format for Multi-language Teams | Why it Helps |

|---|---|---|

| Assembly Guide | Step-by-step Photos | Reduces need for reading text |

| Parts List | Exploded View Diagram | Shows exact position of small parts |

| Safety Warnings | Universal Icons/Symbols | Warns of pinch points or pressure |

| Tech Specs | Metric & Imperial Units | No conversion math errors |

By ensuring your supplier provides these accessible formats, you protect your investment. You ensure that the high-quality parts you bought are treated correctly by the people installing them.

Will they customize training for my models?

Generic videos are okay, but specific ones are better for your brand. I believe in tailoring solutions so you look like the expert to your customers.

Some manufacturers go beyond generic guides and customize training for your specific machine models. This includes creating videos that show your exact equipment and unique work conditions. This targeted approach reduces confusion and speeds up the installation process significantly.

Every machine has its own personality. A Caterpillar D8 7 bulldozer does not behave the same way as a Komatsu PC200 8 excavator. The undercarriage parts look similar, but the installation process has unique quirks. A generic "how to install a track chain" video is helpful, but it might miss the specific steps for the machine you are working on.

As a manufacturer, we can create content that matches your reality. If you are a large distributor, you might focus on a specific brand of machine. We can film a video in our factory using that exact model of undercarriage. We show the tools you need. We show the difficulties you might face with that specific frame.

Private labeling for your business

There is another layer to this customization that my clients love. It is about branding. You are buying from me, but you are selling to your local customers. You want your customers to trust you.

We can produce these training materials with your logo on them. The video intro can feature your company name. The manual can have your contact details on the footer. To your customer, it looks like you produced this high-quality technical content. It builds your authority in the market.

Addressing specific work conditions

We can also customize the content based on where the machine works.

- Mining: If your machines work in a mine, the wear is different. We can add tips on how to check for rock damage during installation.

- Swamp/Wetlands: If you work in mud, we can add a section on how to clean the frame properly before installing new parts to prevent seal failure.

This level of service turns a simple transaction into a partnership. You are not just buying metal; you are buying a training solution that saves your customers money.

| Customization Option | Benefit to You | Benefit to Your Customer |

|---|---|---|

| Model Specifics | Fewer returns due to wrong install | Faster repair times |

| Branded Content | Increases your brand value | Trust in your expertise |

| Condition Specific | Better product performance | Longer part life |

Ask your supplier if they have a media team. Can they shoot a quick video for you? Can they edit a PDF to include your branding? These small touches make a big difference in how your market perceives you.

Are onsite clinics available for my technicians?

Sometimes you need a human expert because videos cannot fix everything. I know that hands-on training is the best way to correct bad habits.

While rare for basic orders, strategic partners often provide onsite clinics or live remote sessions. This allows experts to train your technicians directly on your shop floor. It is the most effective way to correct bad habits and ensure long-term maintenance success.

There is no substitute for watching a master technician at work. In the past, for very large contracts, we would fly engineers to a client’s site. They would spend a few days in the workshop. They would teach the local team how to rebuild a track group safely. They would show the little tricks that are not in the manual—like how to use a pry bar to line up a pin perfectly.

However, travel is expensive and slow. The modern solution is much faster and often just as effective. We now use technology to bring the "clinic" to you.

Remote live support

Imagine your technician is stuck. The idler will not slide into the frame. He is frustrated. He is wasting hours. With our remote support, he can pull out his phone. He calls our engineer via video.

Our engineer sees exactly what is happening in real-time.

"Move the hydraulic jack 9 two inches to the left," our engineer says.

The technician does it. The part slides in. Problem solved in two minutes.

This 7×24 remote support is a game-changer. It is like having a factory expert standing next to you in the mud. We can guide your team through:

- Tool preparation: Checking if you have the right press and torque wrench.

- Removal of old parts: Safe ways to cut old bolts or press out seized pins.

- Installation: Step-by-step visual confirmation.

- Final inspection: Watching the track run to check for alignment.

Train the Trainer

For our distributor clients, we offer a "Train the Trainer" program. We do deep-dive sessions with your lead mechanic or technical manager. We teach them everything we know about metallurgy, heat treatment 10, and wear patterns.

Then, that person becomes the expert for your company. They can train your junior staff. This builds a permanent knowledge base in your company. It makes you less dependent on us for day-to-day questions.

We cover topics that help you sell, too. We explain why a part failed. Was it a material defect? Or was it operator error? Knowing the difference saves you thousands of dollars in warranty claims.

Summary of Support Options

- Onsite Clinic: Best for major fleet overhauls. High cost, high impact.

- Live Video Call: Best for immediate problem solving. Fast, free, and effective.

- Webinars: Good for sales teams to learn product features.

Do not settle for a supplier who disappears after the container leaves the port. You need a partner who answers the phone when the grease hits the floor.

Conclusion

The right supplier provides more than just parts; they offer the knowledge to use them. Demand manuals, videos, and live support to protect your equipment and your profits.

Footnotes

1. Definition and components of heavy equipment track groups. ↩︎

2. Overview of track shoes and their function in undercarriages. ↩︎

3. Specifications and tensile strength data for grade 12.9 bolts. ↩︎

4. Guidelines for measuring and adjusting excavator track tension correctly. ↩︎

5. Technical explanation of final drive mechanisms in heavy machinery. ↩︎

6. Understanding the purpose and layout of exploded view diagrams. ↩︎

7. Official specifications and features of the Caterpillar D8 Dozer. ↩︎

8. Details on the Komatsu PC200 hydraulic excavator capabilities. ↩︎

9. How hydraulic jacks operate for lifting heavy equipment. ↩︎

10. Industrial processes involved in heat treating metal components. ↩︎