Including inspection data 1 as part of your shipment offers assurance of product quality through documented measurements of surface hardness, core hardness, and effective hardened depth (EHD). I know this information provides the transparency you need to confirm parts meet the stringent specifications required for your applications.

Many Chinese manufacturers offer comprehensive inspection data to accompany shipments. They demonstrate compliance with required mechanical properties through detailed measurements, thereby assuring the durability and performance of your undercarriage parts.

Can I Receive a Hardness Map and Sampling Positions for My PPAP?

A hardness map and sampling positions outline the specific areas assessed during testing, essential for the Production Part Approval Process (PPAP). You may require this data as part of your quality assurance protocols.

Yes, detailed hardness maps and defined sampling positions can be provided as part of the quality documentation with your PPAP. This documentation ensures clarity regarding testing procedures and compliance.

Let’s explore the role of these elements in ensuring parts compliance and seamless integration into your operational procedures.

Quality Documentation Components

| Document Type | Description | Benefit |

|---|---|---|

| Hardness Map | Visual layout of tested areas | Confirms comprehensive testing |

| Sampling Positions | Locations assessed for QA | Validates testing accuracy |

These comprehensive documents encapsulate the meticulous testing processes undertaken, providing confidence in the parts’ compliance and functions.

Receiving this documentation supports your efforts in maintaining rigorous incoming quality control.

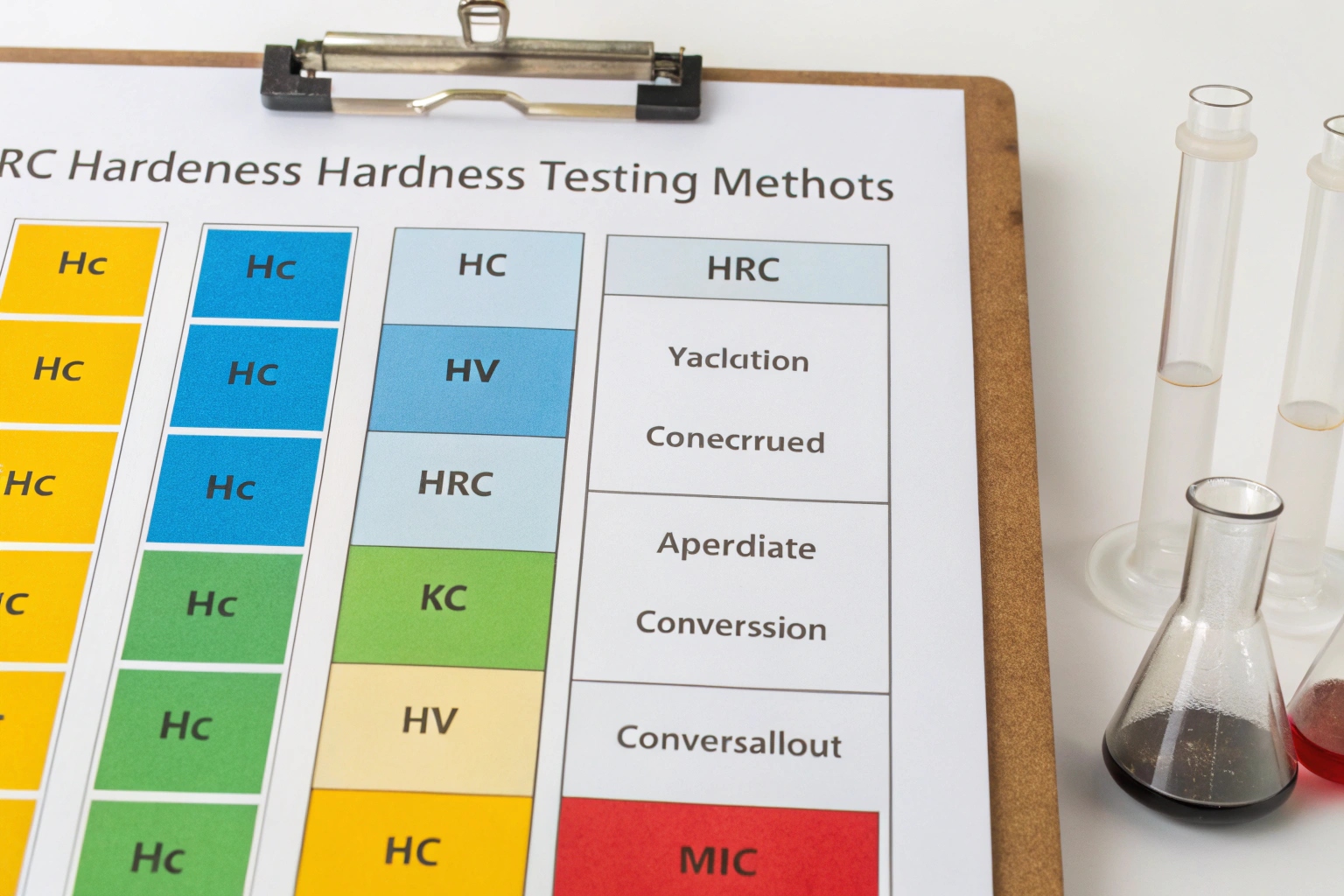

Audits may require detailed insights into the testing methods used, such as hardness scales and conversion references, ensuring compliance with quality requirements.

Of course, we share the detailed test methods, including HB (Brinell), HRC (Rockwell C), and HV (Vickers) measurements, as part of our quality assurance protocols. Conversion references are also available for audit purposes.

Exploring how these methods form part of the audit process demonstrates our commitment to transparency and quality.

Testing Method Details

| Hardness Test Scale | Method Description | Conversion Availability |

|---|---|---|

| Brinell Hardness (HB) | Measures material hardness using indentation | Yes, provided on request |

| Rockwell Hardness (HRC) | Assesses hardness via cone penetration | Included in documentation |

| Vickers Hardness (HV) | Precisely measures thin material layers | Yes, provided on request |

Sharing this information underscores our rigorous approach to verifying parts’ mechanical properties, bolstering audit readiness.

Having these thorough reports facilitates compliance verification, fostering quality assurance throughout operations.

Can I Request 100% Hardness Checks on Critical Rollers I Purchase?

A thorough examination, such as 100% hardness checking, for critical components is integral to upholding system reliability and performance standards. Your focus might be on rollers and similar parts.

Yes, per your request, we can perform complete hardness checks on critical rollers 2, ensuring every part matches the required specifications.

Delving into how these checks are conducted reinforces the reliability and accuracy of component hardness evaluations.

Comprehensive Inspection Procedures

| Inspection Type | Description | Reliability Insights |

|---|---|---|

| 100% Hardness Checking | Full-scale inspection of each component | Ensures comprehensive quality |

| Batch-Level Testing | Representative sampling | Verifies overall consistency |

Comprehensive inspections provide certainty that each component consistently performs to high standards throughout its lifespan.

Offering these extensive checks attests to our commitment to maintaining uncompromised product integrity.

How Do You Store and Trace Raw Test Data in Case I Need It Later?

Access to stored raw test data might be critical for future reference or analysis. It’s important to ensure such data is maintained correctly for traceability over time.

We maintain comprehensive electronic storage of raw test data through advanced ERP systems 3, ensuring it’s traceable for auditing or assessment needs.

Exploring our data management protocols showcases their importance in fostering traceability and transparency.

Data Management and Traceability

| Storage Method | Description | Compliance Benefit |

|---|---|---|

| ERP System | Digital storage of quality and test data | Easily traceable records |

| Data Accessibility | Facilitated by secure digital means | Supports reliable audits |

Streamlined traceability processes ensure you can access crucial compliance data when needed, enhancing operational transparency.

Maintaining these records supports informed decision-making and ongoing parts quality assurance.

Conclusion

Inspection data inclusion signifies a commitment to quality and transparency, providing crucial verification for undercarriage parts’ reliability and robustness.

Footnotes

1. Understanding inspection standards and protocols. ↩︎

2. Inspecting critical rollers for consistent quality. ↩︎

3. ERP systems for managing and tracing data. ↩︎