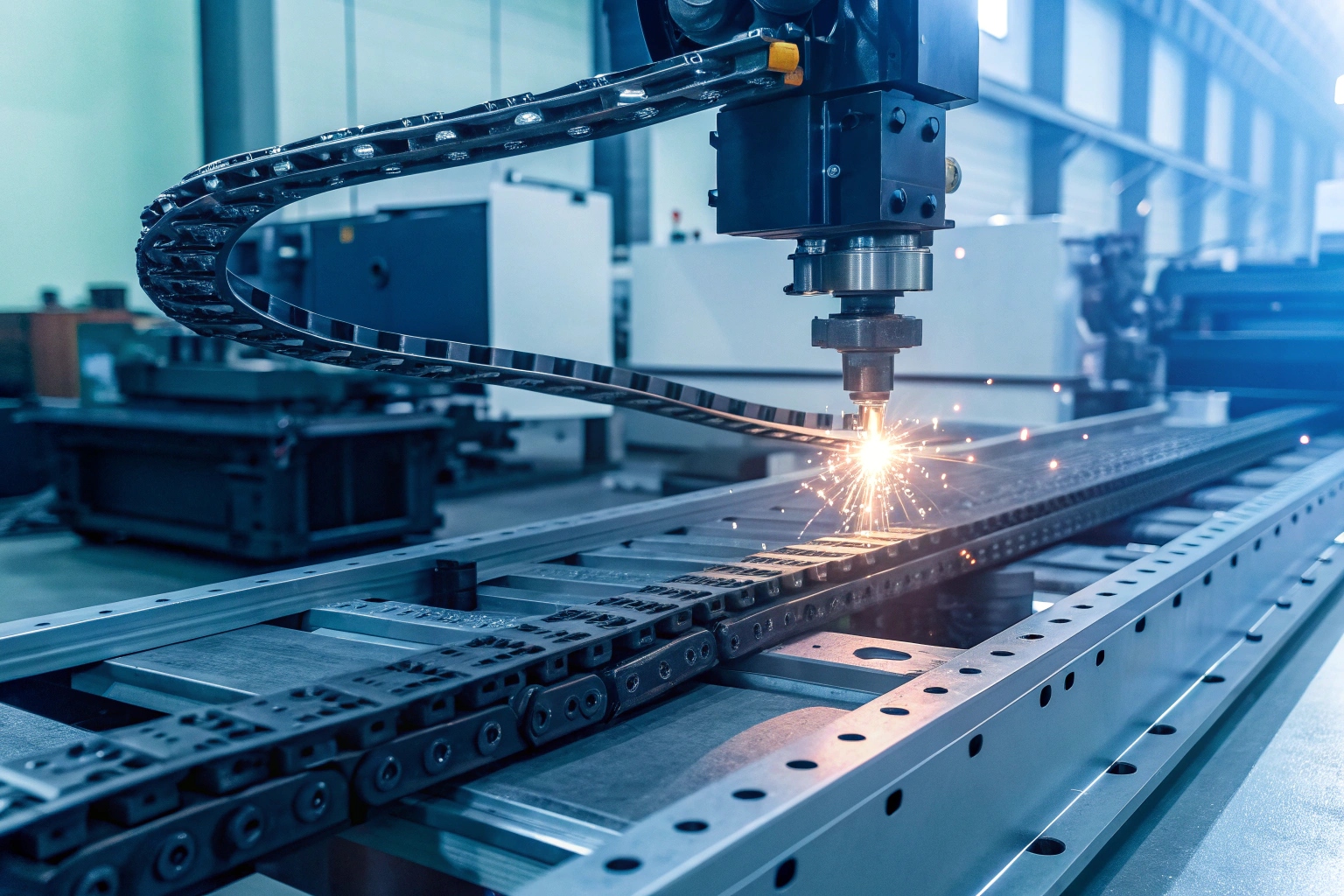

Precise control over track chain pitch 1 and tolerances is vital to ensuring the reliability and performance of excavator undercarriage parts. I know you’re focused on ensuring these specifications are met consistently to avoid operational disruptions and maintain equipment longevity.

Our approach involves employing advanced machining processes and precision technologies like CNC systems 2 to achieve tight control over pitch dimensions. Regular calibration ensures the machinery remains precise, complemented by detailed inspections at every production stage. Laser systems and statistical control methods are integral for maintaining consistency across batches.

Can I Review Your Pitch Measurement Plan and Gauge Capability (GR&R)?

Understanding the measurement plans and gauge capability is crucial for verifying compliance with pitch specifications. Your concern might be ensuring the accuracy and reliability of these measurement tools.

You can absolutely review our pitch measurement plan and gauge capability (GR&R). This includes detailed methodologies and calibration protocols that confirm tools’ precision and reliability in measuring track chain pitch.

Explore these capabilities further to discover how they ensure high standards of measurement accuracy and consistency.

Pitch Measurement and Gauge Capability

| Aspect | Description | Benefit |

|---|---|---|

| Measurement Plan | Comprehensive procedure overview | Ensures measurement accuracy |

| Gauge Capability (GR&R) | Detailed capability analysis | Guarantees reliable measurements |

Reviewing these procedures reinforces trust in our precision methodologies, ensuring each component aligns with specifications.

Such reviews are instrumental in satisfying stringent quality demands, establishing confidence in applied processes.

Statistical control charts, such as X-bar and R charts 3, are crucial for monitoring production consistency. Your goal is to have insight into how pitch stability is maintained across production.

Indeed, we share statistical control charts that demonstrate pitch consistency throughout production runs, highlighting adherence to defined specifications.

Discovering how these charts support production control showcases their role in achieving consistent manufacturing outcomes.

Pitch Consistency Control

| Chart Type | Description | Benefit |

|---|---|---|

| X-bar Chart | Averages plotted for visual stability monitoring | Ensures consistent production |

| R Chart | Range data to indicate variability | Highlights process control |

These data-driven insights affirm our rigorous approach to controlling pitch dimensions, ensuring reliable part performance.

Analyzing such charts helps in confirming consistent accuracy in maintaining tight production tolerances.

Can You Meet OEM Pitch Specs Under My Cold-Weather Application?

Meeting OEM specifications 4 under varied conditions, such as cold weather, is essential for maintaining equipment reliability. Your requirements may include ensuring pitch remains stable even under challenging climates.

Our production capabilities can meet OEM pitch specs under cold-weather applications, adapting processes to assure operational integrity through material and manufacturing adjustments.

Discussing the adjustments made in response to environmental demands underlines confidence in product adaptability.

Adapting to Cold-Weather Applications

| Feature | Adaptation Strategy | Performance Assurance |

|---|---|---|

| Material Selection | Enhanced alloy compositions | Maintains dimensional stability |

| Manufacturing Process | Adjusted processes for temperature resilience | Ensures operational reliability |

Commitment to maintaining pitch integrity under various conditions validates production flexibility and quality assurance strategies.

Such adaptations underscore expertise in delivering stable performance across diverse manufacturing specifications.

How Do You Prevent Pitch Growth Under Heavy Abrasion?

Preventing pitch growth due to heavy abrasion 5 is vital for sustaining component functionality and longevity. Your focus may be on ensuring durability through comprehensive control measures.

Preventing pitch growth involves implementing stringent material controls, optimized heat treatment protocols, and ongoing inspections. These ensure high-strength characteristics necessary to resist wear.

Insights into methods to control pitch growth amidst demanding conditions illustrate our dedication to quality and reliability.

Controlling Pitch Growth

| Method | Description | Benefit |

|---|---|---|

| Material Control | High-strength alloys to resist fatigue | Reduces wear-induced changes |

| Heat Treatment | Precise protocols for optimally hardened surfaces | Maintains dimensional stability |

Enhancing these areas ensures components retain their required specifications, establishing your equipment’s durability.

Preventing pitch alterations confirms part reliability through dedicated control and specification adherence practices.

Conclusion

Precision and consistency in controlling track chain pitch are fundamental to ensuring the reliable operation of excavator undercarriage parts, affirming dimensional stability under demanding conditions.

Footnotes

1. Explore track chain design methodologies. ↩︎

2. Learn about CNC systems in precision machining. ↩︎

3. Understand statistical process controls. ↩︎

4. OEM specification adaptation strategies. ↩︎

5. Abrasion resistant material controls. ↩︎