In the realm of undercarriage parts for excavators & bulldozer, identifying whether components are cast or welded can be puzzling. Personally, I find verifying these details essential to ensure the suitability and reliability for specific operations.

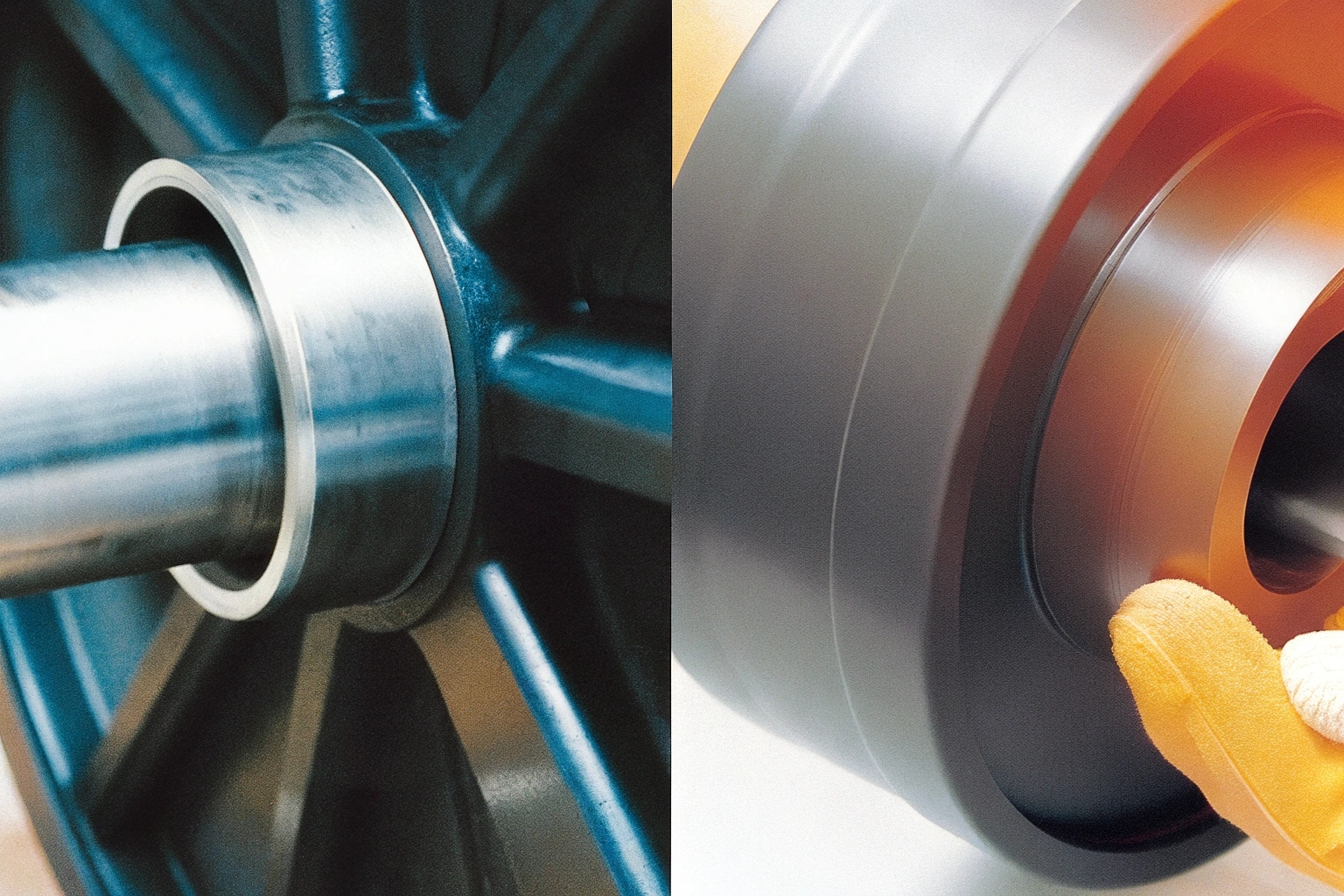

The primary construction method for idlers and carrier rollers 1 is casting. This method delivers uniformity and strength, ideal for heavy-duty applications. Some instances may require welded carrier rollers to fulfill specific support necessities. The casting method’s consistency provides a reliable performance baseline across varying conditions. We maintain detailed UT (Ultrasonic Testing) 2, MT (Magnetic Particle Testing) 3, and RT (Radiographic Testing) 4 records. These ensure compliance with safety benchmarks and offer historical performance validation, aiding maintenance predictions.

Can I set acceptance levels for internal defects per ASTM/ISO for my undercarriage parts for excavators & bulldozer?

Internal defects in undercarriage parts for excavators & bulldozer can severely impact their performance and lifespan. Being in control of acceptance levels is crucial. I always prioritize adhering to recognized standards.

Our clients can set acceptance standards based on ASTM/ISO guidelines 5, ensuring stringent internal defect scrutiny. By aligning with these international benchmarks, we guarantee consistent quality across all product batches. For internal defects, these detailed standards offer a guide for what discrepancies are acceptable or need correction, promoting quality assurance.

Setting acceptance levels involves meticulous review of material properties and testing results. These levels serve as prerequisites in evaluating an undercarriage part’s readiness for deployment. By setting targets formally, the clarity in requirements drives improved design and production accuracy. ASTM and ISO provide a comprehensive framework for acceptance criteria, enhancing traceability and accountability. Implementing these standards reinforces reliability in the supplied undercarriage parts for excavators & bulldozer, encouraging transparent quality discussions between the supplier and the client.

Will you provide NDT coverage maps and sampling ratios for my batches for my undercarriage parts for excavators & bulldozer?

Understanding the scope of testing through coverage maps 6 and sampling ratios can give profound insights into component reliability. Access to these considered tools boosts assurance.

We indeed offer comprehensive NDT coverage maps and sampling ratio documentation, detailing the extent of our testing protocols per batch. By reviewing these, idlers and carrier rollers undergo rigorous assessments ensuring they meet established quality metrics. Maps give visual overviews of tested areas, while ratio data convey the thoroughness of inspection methods implemented.

NDT maps illustrate test-focused areas, tracing from initial casting or welding through final inspection. Sampling ratios indicated in our reports inform the proportion of units undergoing specific tests. This ensures coverage adequacy across varying parts sizes and complexity. The maps and ratios promote transparency and accountability, highlighting areas under scrutiny and confirming standards adherence. With these insights, clients can derive confidence in the quality and performance expectations linked with their parts.

Porosity can compromise the integrity of undercarriage parts for excavators & bulldozer. As someone deeply involved in quality assurance, I regard mitigating porosity as crucial to elevating component resilience.

Our foundry employs process controls 7 specifically designed to minimize porosity issues in component castings. These steps enhance performance longevity and structural integrity, offering clients dependable undercarriage parts for excavators & bulldozer cultivated through refined methodologies.

We engage advanced techniques in our foundry processes, integrating specialized materials and procedures to reduce porosity occurrence. Automated measures monitor environment adaptability concerning temperature, humidity, and material flow dynamics. Technical teams regularly conduct assessments to ensure process effectiveness aligns with industry standards. These efforts manifest in material optimization, controlling porosity at its core, ultimately achieving robust and dependable undercarriage components. Clients benefit from these rigorous practices, ensuring component durability across diverse operational conditions.

Do you allow on-site NDT witness for my key shipments for my undercarriage parts for excavators & bulldozer?

Having someone present during NDT processes 8 provides reassurance and transparency, affirming impartiality during crucial testing phases.

We gladly accommodate on-site NDT witness opportunities, offering clients firsthand experience and affirmation during pivotal inspection stages of key shipments. Our teams coordinate visits ensuring client representatives can observe testing processes firsthand. This reinforces our commitment to quality and transparency.

Witness opportunities encapsulate NDT techniques ranging from ultrasonic and magnetic particle testing to radiographic assessments. Witnessing these inspections ensures compliance to client standards and transparency in results. Such interactions forge trust and convey confidence in our quality assurance endeavors. Our focus lies in transparency and credibility, offering clients avenues to affirm part performance aligns with their expectations through first-hand verification.

Conclusion

Understanding undercarriage part production and testing processes is key to ensuring quality and reliability. Transparency in records and witnessing drives improvement.

Footnotes

1. Overview of idlers and carrier rollers construction methods. ↩︎

2. Explains how ultrasonic testing ensures material integrity. ↩︎

3. Details magnetic particle testing in defect detection. ↩︎

4. Learn about radiographic testing for internal defects. ↩︎

5. Understanding ASTM/ISO standards for part quality. ↩︎

6. Importance of coverage maps in NDT processes. ↩︎

7. Foundry controls to improve part quality by reducing porosity. ↩︎

8. Explanation of NDT processes and their benefits. ↩︎

9. Benefits of certification compliance in quality assurance. ↩︎

10. Role of client witnessing in maintaining transparency. ↩︎