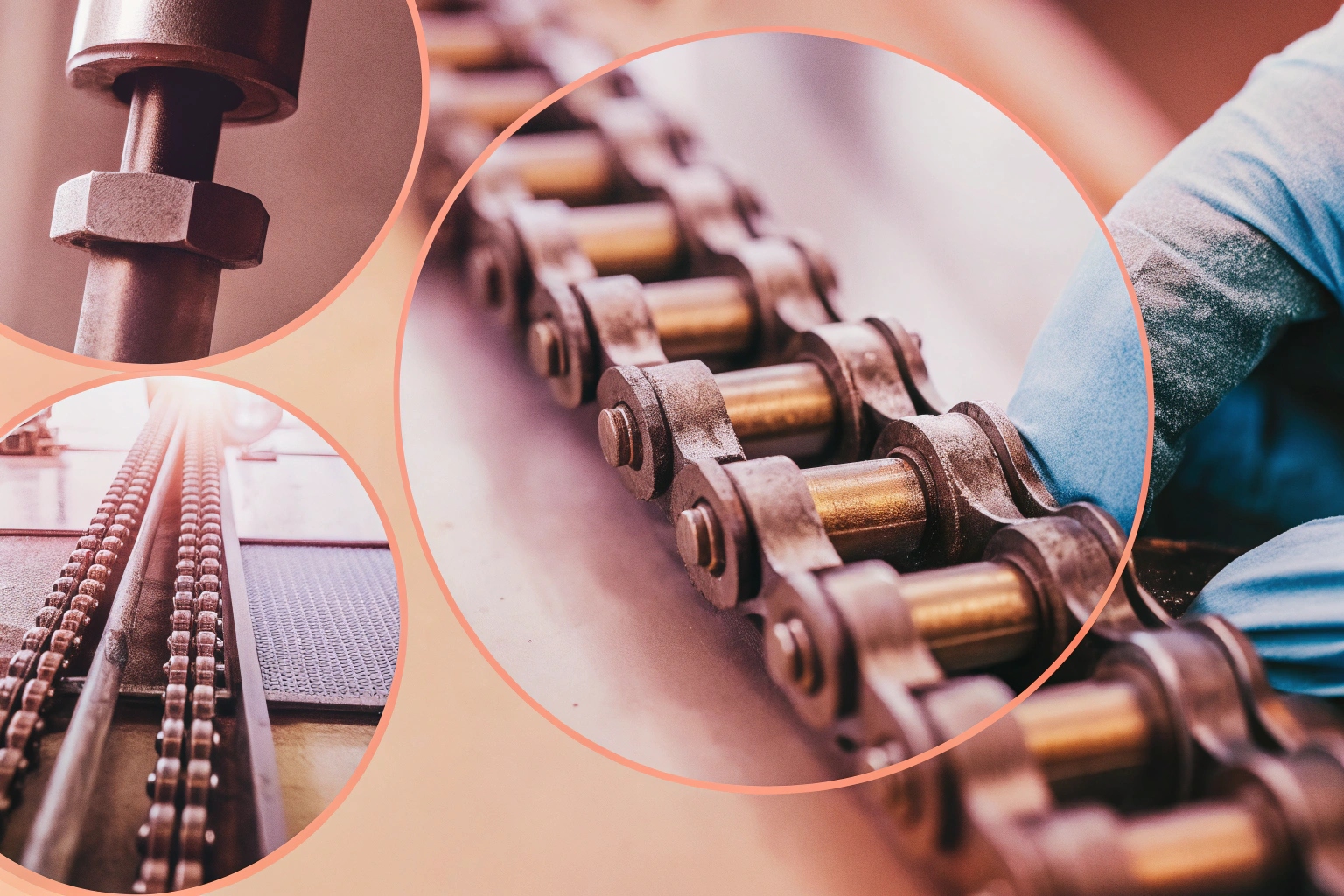

In the realm of international trade 1, ensuring product quality before shipment is crucial. I have often wondered about the possibility and practicality of conducting a 100% final inspection on undercarriage parts for excavators & bulldozer 2. This level of scrutiny can be vital in preventing costly returns and ensuring that all parts meet the required specifications before they even leave the factory.

For those overseeing the purchase of precision parts like undercarriage components, having a 100% inspection can be indispensable. Most suppliers do provide options for comprehensive inspections, especially if this has been established in the initial contract 3. The process is more rigorous than standard AQL sampling 4 and can include everything from visual to dimensional checks.

As an informed consumer, understanding the options available and the logistics of a 100% inspection can prevent issues before they arise.

How Much Extra Does it Cost for a 100% Inspection Versus Standard AQL Sampling?

The cost difference between a 100% inspection and an AQL sampling inspection can vary significantly. In my experience, the decision to carry out a full inspection often hinges on balancing cost against the assurance of quality.

Requesting a full inspection typically incurs higher costs due to the labor and resources involved. However, for critical components where failure is not an option, the additional expense is often worth it. Costs usually fall on the buyer unless otherwise agreed upon.

Dive deeper into Inspection Costs

Inspection costs can be categorized based on the type of inspection service utilized. Suppliers often have internal teams and infrastructure for quality checks. For instance, when parts are complex, internal checks might be carried out using CMM (Coordinate Measuring Machine) 5 or other advanced technologies. Supply chains can benefit from internal assessments, which may integrate fees into the product’s price, especially for standard inspections.

-

Supplier’s Self-Inspection: This usually involves either incorporating minimal fees into the product price or applying project-based additional charges. The latter often happens in custom orders demanding specific checks.

-

Third-Party Inspection: Engaging an external agency such as SGS or TUV 6 is more transparent in terms of costs. These agents typically charge per day or based on the number of dimensions measured. Expect these costs to be outside the product price, demanding separate acknowledgment.

-

Cost Comparison: Inspection Type Cost Structure Remarks Supplier’s Internal Integrated with unit pricing or separate More economical, overseen by the supplier Third-Party Service Per dimension/day, outside product pricing Proves objectivity, usually higher cost

Each type of inspection has its merits. The choice frequently rests on the complexity of the parts, buyer requirements, and budgetary constraints.

What Critical Dimensions Should be Checked?

Recognizing which dimensions are critical for inspection can determine the operational success of undercarriage parts for excavators & bulldozer. In our experience, places of importance include track pitch 7 and roller shell diameter.

These dimensions are pivotal as they impact the wear-and-tear and functional performance of the machinery. Suppliers often have standard checks for such dimensions, but custom orders might necessitate more nuanced criteria.

Delving into Dimension Checks

For precision components, understanding which dimensions need checking is vital. Here are some essential dimension checks for undercarriage parts for excavators & bulldozer, identified based on their functional importance:

-

Track Pitch: The spacing accuracy impacts the track’s grip and terrain adaptability. Incorrect pitch sizes result in poor handling and premature wear 8.

-

Roller Shell Diameter: This affects weight distribution and part lifespan. Accurate diameters ensure smooth operation and reduce stress on other parts.

-

Table of Critical Dimensions: Dimension Recommended Check Freq. Impact on Functionality Track Pitch Every batch Affects grip, handling Roller Shell Diameter Specific orders or new productions Impacts lifespan, stress on adjacent parts

Critical dimensions ensure structural and operational integrity. Specifying these to suppliers ensures both parties are aligned on quality expectations.

Can I Receive the Full Inspection Report With Photos and Measurements for My Records?

Receiving a detailed report from suppliers is not only possible but often a recommended best practice. From personal experience, these reports provide assurance and a baseline for quality assessments 9.

Most manufacturers are willing to provide these reports, especially if requested at the time of purchasing. Comprehensive and tailored documentation can mitigate potential disputes and improve transparency across the supply chain.

Understanding Inspection Reports

Understanding reports involves more than just verifying numbers. A thorough analysis of photographs and measurements offers insights into production consistency and competence.

-

Contents of Reports:

- Visual Evidence: Through photos, buyers can independently verify part conditions.

- Measurement Verifications: Subsequent checks of critical dimensions like diameters or lengths validate conformity with specified tolerances.

- Format and Delivery: Reports can be delivered digitally, which is standard practice for efficiency and ease of access.

-

Table of Inspection Report Elements: Report Element Purpose Importance Photos Visual verification of part status Prevents visual miscommunications Dimension Checks Confirms adherence to specs Ensures fit and function integrity

These reports act as proof of quality and a tool for continual improvement.

Can I Hire My Own Third-Party Inspector (Like SGS) to Perform This Check at Your Factory?

Leveraging third-party inspection services 10 like SGS is commonplace and often recommended when seeking unbiased evaluations. Their involvement can significantly enhance confidence in product quality and validity, especially in international trade.

Having dealt with various inspectors, I can attest to the professionalism and detailed reports they provide, far surpassing standard internal checks in some cases.

Exploring Third-Party Inspections

Using these external checks, especially by experienced inspectors like SGS, can be a strategic approach to ensuring products meet high expectations. Here’s how they operate:

-

Services Offered:

- Comprehensive Inspections: Cover critical dimension checks, visual inspections, material analysis, and more.

- Documentation and Reporting: Detailed reports provide peace of mind, facilitating customs and client acceptance procedures.

-

Benefits of Hiring Third-Party Inspectors:

- Objective Assessments: Avoid conflict of interest with suppliers.

- Standardization: Ensure adherence to international standards.

- Verified Expertise: Services come with the assurance of recognition and acceptance globally.

-

Considerations:

- Cost: Often higher than internal checks.

- Coordination: Requires logistics arrangement between supplier, buyer, and inspector.

These inspections not only add an extra layer of quality assurance but allow for significant mitigation of overseas transaction risks.

Conclusion

A 100% final inspection on undercarriage parts for excavators & bulldozer before shipping from China is feasible and beneficial, though it involves certain costs and logistics that must be carefully managed.

Footnotes

1. Overview of best practices for international trade agreements. ↩︎

2. A technical guide to heavy machinery undercarriage components. ↩︎

3. Learn how to define quality standards in supplier contracts. ↩︎

4. Explanation of Acceptance Quality Limit (AQL) in manufacturing. ↩︎

5. Details on how Coordinate Measuring Machines (CMM) verify part dimensions. ↩︎

6. Comparing services offered by leading third-party inspection agencies like SGS and TUV. ↩︎

7. The engineering principles behind track pitch and its importance. ↩︎

8. Common causes and prevention methods for premature equipment wear. ↩︎

9. Guide to establishing benchmarks for manufacturing quality control. ↩︎

10. The benefits of using objective third-party inspection services. ↩︎