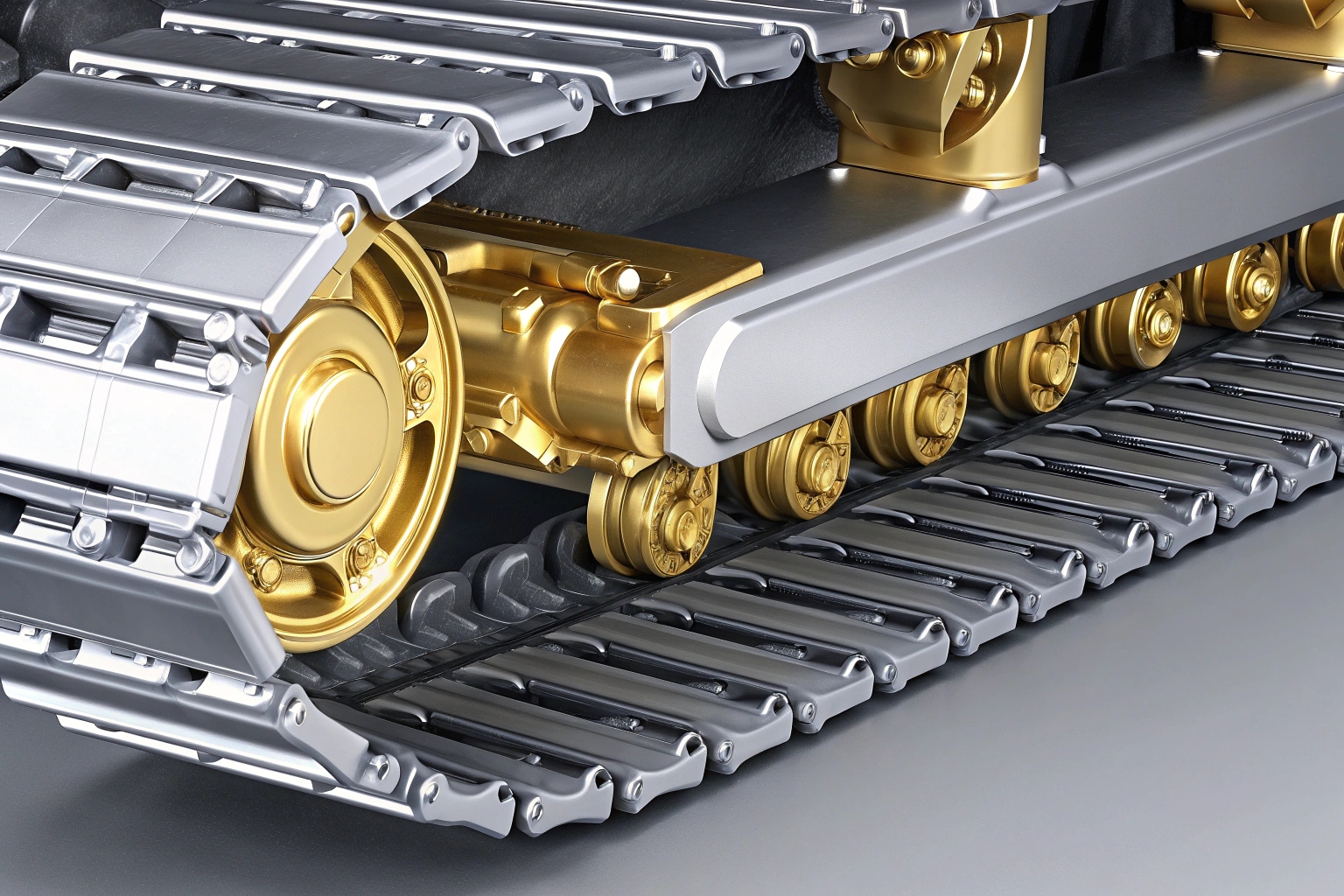

Have you ever been frustrated by standard excavator parts that just don’t fit your specific needs? I know I have, and that’s why I began exploring customized undercarriage parts. It was time to find something that truly fits my equipment.

Yes, you can absolutely get customized designs for excavator undercarriage parts 1, including special duty components, thicker track shoes 2, and longer idlers 3. This service is available from various specialist manufacturers who offer customized solutions tailored to your specific requirements.

Finding solutions for non-standard equipment needs can be challenging, but rest assured, specialized firms have the expertise to design and deliver. Let’s explore how you can achieve this for your machinery.

What Drawings and Specs Must I Provide for Customization?

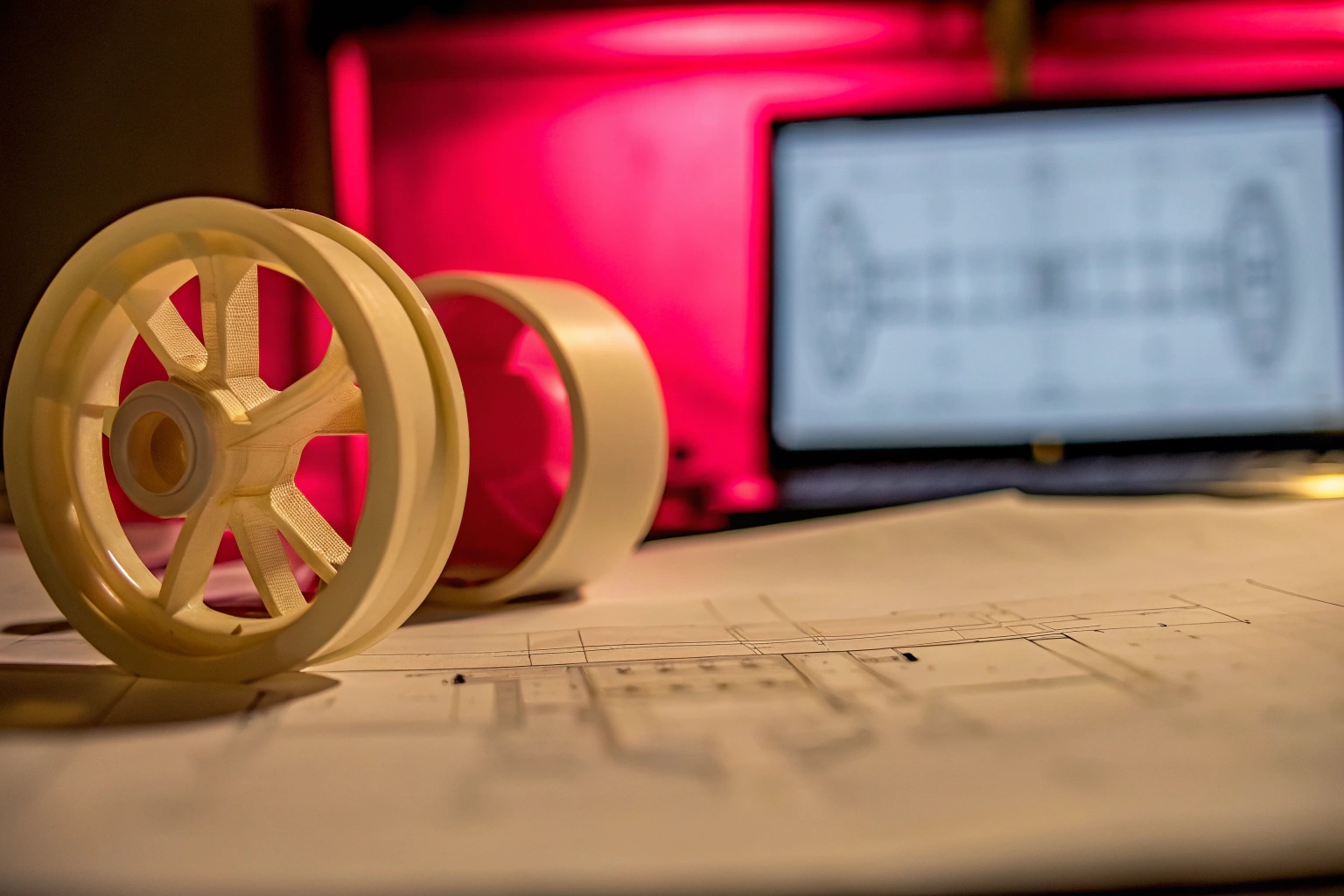

Understanding how to communicate your needs is crucial when ordering custom parts. I once wondered what exact specifications manufacturers needed to start the design process. It seemed like a daunting task, but with the right guidance, it became straightforward.

To begin the customization process, you need to provide detailed drawings and specifications, including dimensions 4, material preferences, and performance criteria. Collaborate with your supplier to ensure every detail is captured, resulting in parts that fit and function perfectly.

Accurate communication is vital. The more precise your specifications, the better your supplier can meet your needs. This includes providing CAD drawings 5 or working closely with the design team to translate your ideas into workable solutions.

Table 1: Specification Details

| Specification Type | Description |

|---|---|

| Dimensions | Exact measurements of the parts required. |

| Material | Desired material type for durability or weight. |

| Functionality | Specific performance criteria. |

How Do Custom Parts Impact Lead Time and MOQ?

I worried about the time and volume commitments involved in customizing parts. Lead times and Minimum Order Quantities (MOQs) can significantly impact planning and budget, but understanding these factors helps mitigate surprises.

Customization often results in longer lead times 6 and higher MOQ requirements compared to off-the-shelf parts. However, working closely with your supplier can help manage expectations and ensure timely delivery of your custom-designed components.

Properly planning for custom orders includes understanding supplier capabilities and constraints. Engage with them early to align timelines and resources, as this coordination is key to ensuring satisfaction with the process and final product. A clear understanding of Minimum Order Quantities 7 is essential for budgeting.

Table 2: Lead Time and MOQ Considerations

| Factor | Impact |

|---|---|

| Design Complexity | Complex designs may increase lead time. |

| Material Availability | Rare materials can affect both lead time and cost. |

| Order Volume | Larger orders might benefit from scaled efficiencies. |

Can My Supplier Run Field Tests for My Unique Designs?

Testing a new design in the field can provide invaluable feedback. In my experience, field testing has often been the difference between a design that works on paper and one that excels in practice.

Many suppliers offer the service of running field tests 8 to evaluate the performance of your unique designs. This is an excellent way to ensure your custom parts meet all operational requirements 9 before full-scale production.

Discuss this option with your supplier. Field testing can identify potential improvements and confirm design assumptions, providing peace of mind that your custom parts will perform effectively in real-world conditions.

Table 3: Benefits of Field Testing

| Benefit | Description |

|---|---|

| Performance Validation | Confirms the new design meets operational needs. |

| Real-World Feedback | Provides data for potential improvements. |

| Risk Mitigation | Reduces the likelihood of design failure. |

Will My Warranty Cover Custom-Configured Components?

The assurance of a warranty is as important as the parts themselves. Understanding warranty coverage on custom parts can influence the decision to proceed with customization.

Yes, many suppliers do offer warranties on custom-configured components, but it’s essential to discuss this upfront. Warranties may vary, so ensure that all terms are clear and cover the specific conditions of use for your custom parts. Reviewing warranty coverage 10 prevents future disputes.

Review warranty terms carefully. This can prevent misunderstandings and provide security if your custom parts do not meet expectations. A strong relationship with a reputable supplier enhances trust and clarity regarding after-sale support.

Conclusion

Customization of excavator undercarriage parts offers tailored solutions for specific needs, enhancing performance and durability. Engaging with knowledgeable suppliers and providing precise specs are key to successful customization.

Footnotes

1. Overview of undercarriage mechanics and engineering principles. ↩︎

2. Explanation of track shoe functions in heavy machinery. ↩︎

3. Role of idlers in maintaining track tension. ↩︎

4. Standards for accurate industrial measurement and specifications. ↩︎

5. How CAD software facilitates precise custom engineering. ↩︎

6. Definition and business impact of manufacturing lead times. ↩︎

7. Guide to understanding Minimum Order Quantities in procurement. ↩︎

8. Importance of field testing for product validation. ↩︎

9. Defining operational standards for equipment performance. ↩︎

10. Insights into business warranty laws and protections. ↩︎