When discussing new projects, it’s always crucial to start with samples. I always push for clear steps to ensure everything aligns perfectly from the get-go, avoiding costly mistakes 1 later.

For undercarriage parts for excavators & bulldozer, ordering samples or small trial batches is straightforward. These initial pieces allow you to assess part performance accurately 2 before scaling up to more significant orders. Sample costs vary according to the parts’ complexity, tool design, and the involved manufacturing processes 3. Typically, the manufacturing schedule determines the lead times, stretching from weeks to months.

Transitioning into production, let’s break down each important aspect when handling these initial batches.

Will you credit my sample fees against mass orders I place?

Sample orders can be expensive, and I get it—no one wants unnecessary costs. Getting credits can alleviate financial strains and highlight flexibility and partnership in your supplier.

You can indeed receive credits for your sample fees against mass orders. We understand the strategic importance of this, particularly when scaling or budgeting for large projects. Usually, these costs include tooling and material charges 4, offering transparency and reassurance to you.

In bulk orders, crediting sample costs makes financial sense. Suppliers commonly adjust these charges against future mass orders, acting as goodwill gestures. This approach benefits both parties, forming a partnership that’s strategic and long-term focused.

Can you expedite samples for my urgent tenders?

Tight deadlines are a familiar story, right? Nothing is more crucial than receiving samples on time for pressing project bids or tenders 5. Expedited processing can make or break your competitive edge.

Expedited sample services are available for urgent scenarios. Balancing speed with quality, we adjust production timelines to prioritize critical deliveries. We aim to meet your urgent project requirements smoothly and efficiently.

Expediting samples involves several considerations. Firstly, we evaluate production schedules 6 to open slots for your urgent needs. Secondly, understanding material availability and workforce capacity helps speed up processes. Additionally, communication plays a vital role; clear project specifics ensure aligned timelines and quality adherence. Finally, incurring additional costs for faster service means strategically weighing urgency against budget constraints.

Do you offer sample kits covering the full set for my model?

Imagine receiving a comprehensive set of samples, every part of your model tested and verified. Sounds ideal, right? Full kits not only aid performance checks but also stress-test compatibility 7.

Yes, comprehensive sample kits are available for your model. These kits ensure every component aligns with your specifications and functions seamlessly together. Providing you a holistic view prevents future discrepancies.

When providing complete kits, planning and coordination are vital. Firstly, having a clear understanding of your technical specifications 8 ensures kit accuracy. Secondly, aligning internal processes like tooling design and production schedules avoids disruptions. Further, it’s critical to engage skilled technicians who conduct rigorous quality checks 9 on each component. Packages containing all relevant parts, checked for dimensions and quality, offer reassurance and ultimate readiness.

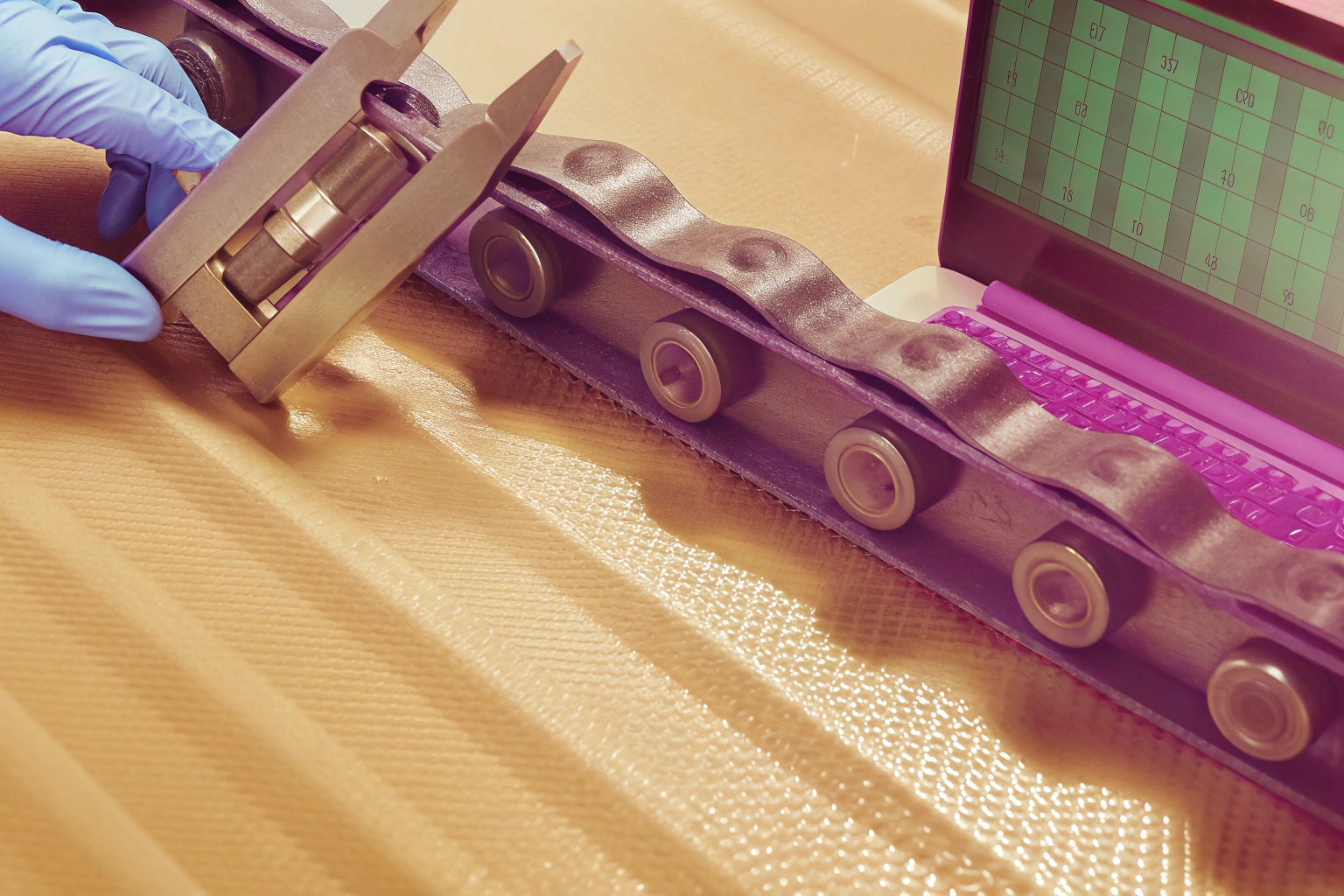

Will you photograph and dimension-check samples before shipping to me?

Receiving accurately measured and documented samples is reassuring, right? Photos and dimension checks prior to dispatch ensure integrity upon arrival, fostering trust and transparency.

Absolutely, every sample undergoes thorough dimension checks and photographic documentation before shipment. This step guarantees you receive precisely what you expect, aiding in verification and approval.

Photographic documentation and dimension checks require meticulous procedures. Firstly, precision instruments are used to measure part dimensions accurately. These metrics ensure products meet specified tolerances 10. Secondly, high-resolution photography captures intricate details, providing visual data for reference. This catalog of information bolsters transparency and aids your decision-making, ensuring a partnership rooted in quality assurance.

Conclusion

Sample requests are pivotal in validating performance before committing to full-scale production. Our processes ensure accurate assessments, cost transparency, and timely delivery tailored to your unique needs.

Footnotes

1. Guide on risk management in manufacturing projects. ↩︎

2. Methods for performance testing of industrial parts. ↩︎

3. Overview of common undercarriage manufacturing techniques. ↩︎

4. Learn how tooling and material costs are calculated. ↩︎

5. Understand the requirements of industrial tendering processes. ↩︎

6. Importance of optimizing production schedules in manufacturing. ↩︎

7. Best practices for compatibility and stress-testing components. ↩︎

8. How to read and interpret technical specification documents. ↩︎

9. The role of rigorous quality checks in component manufacturing. ↩︎

10. Explanation of engineering tolerances and their importance. ↩︎