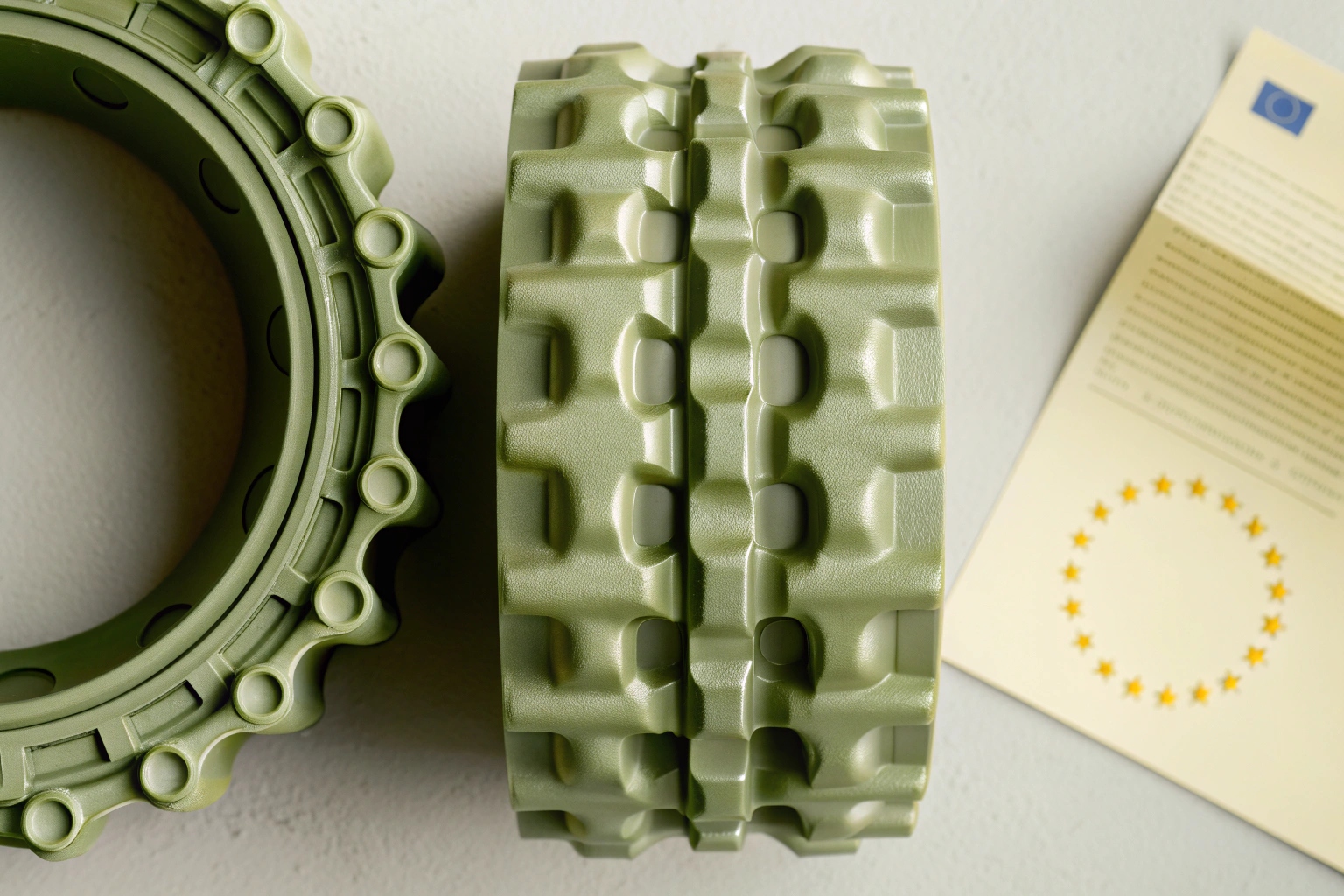

Undercarriage parts are critical components of heavy machinery 1, and environmental compliance documents ensure these parts meet regulatory standards. I often worry about the environmental impact of the parts I purchase, and I need assurance they meet various regulations.

Suppliers typically provide environmental compliance documents like RoHS and REACH. These documents certify that products meet specific environmental regulations, ensuring they’re free from hazardous substances. Beyond these general documents, suppliers must tailor statements for US-specific rules, like California Proposition 65, to safeguard against litigation 2.

Compliance documents are crucial for ensuring environmental responsibility, and suppliers must manage and update these documents to reflect changes in legislation. Let’s explore whether your supplier is equipped to handle this task.

Are your products compliant with EU REACH and RoHS regulations?

Environmental regulations like REACH and RoHS are vital in limiting hazardous materials in products 3, safeguarding health and the environment. Such compliance is essential for market access in the EU, a concern I have when sourcing from global suppliers.

Suppliers typically provide REACH and RoHS compliance documents upon request. These documents validate that products adhere to EU regulations regarding harmful substances, restricting substances like lead and cadmium. Suppliers following these directives ensure their parts meet environmental standards, crucial for mitigating environmental risks.

| Regulation | Purpose | Key Substances | Requirement |

|---|---|---|---|

| REACH | Manage chemical substances in the EU | SVHCs (e.g., lead, cadmium) | SVHC declaration and MSDS |

| RoHS | Restrict hazardous substances in electronics | Lead, mercury | Compliance certification |

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) 4 dictates chemical substance management within the EU. Suppliers comply with REACH by providing Material Safety Data Sheets (MSDS) 5 and Substance of Very High Concern (SVHC) declarations 6. These documents demonstrate compliance through various tests, ensuring substances above 0.1% weight do not exceed safe levels. Similarly, RoHS (Restriction of Hazardous Substances) restricts hazardous materials in electronics, mandating standards for lead, mercury, and other substances.

Both regulations require maintenance and regular updates, especially when new SVHCs or RoHS substances are added. Suppliers must ensure transparent communication and documentation management, critical aspects of compliance. Small suppliers might initially lack comprehensive documentation, but they can obtain necessary certifications from manufacturers if requested.

Can you provide material declarations or testing reports for specific substances?

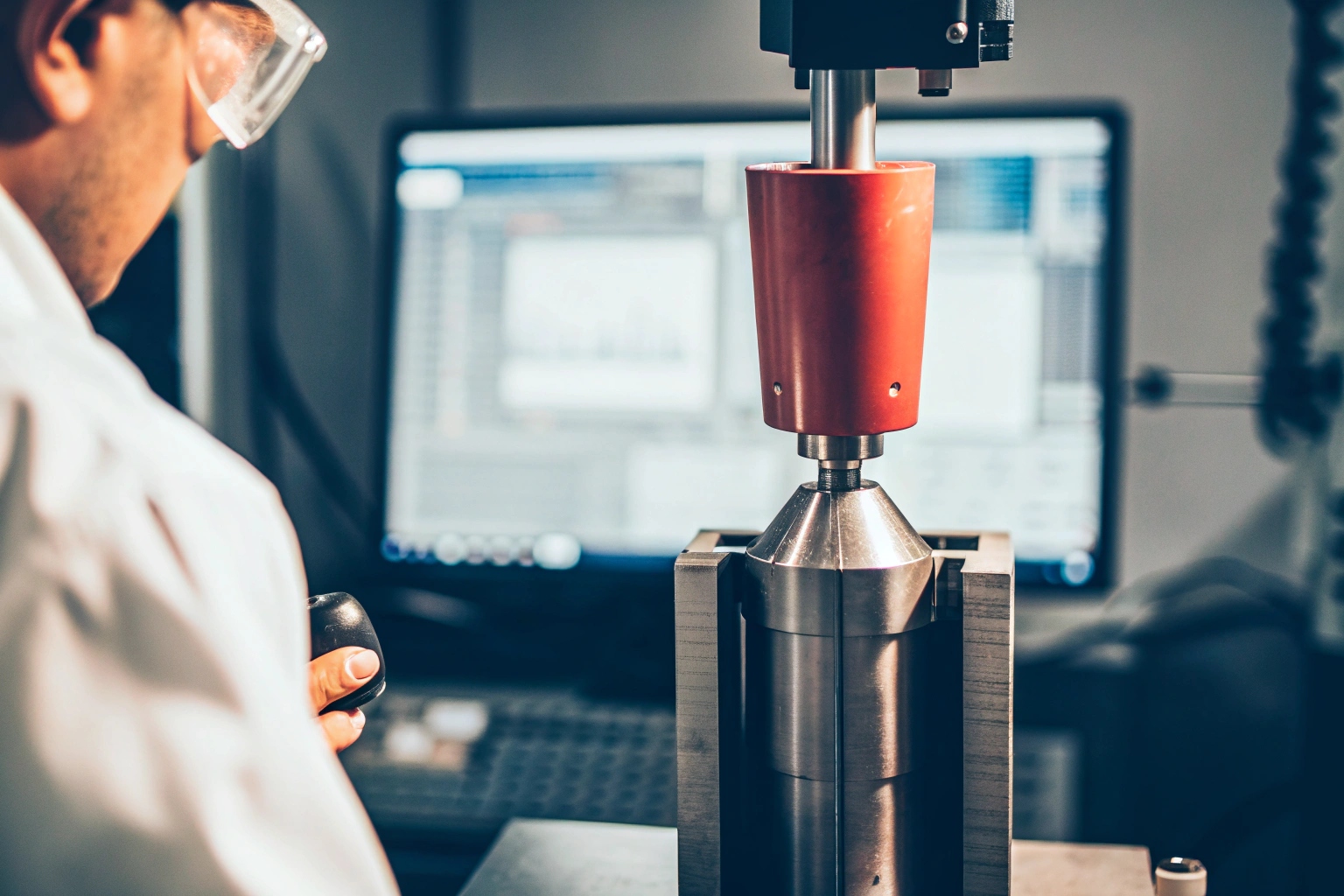

Material declarations and testing reports verify that products don’t contain harmful substances 7, reducing risks and ensuring compliance. Knowing the integrity and reliability of supplier documentation offers peace of mind concerning product safety.

Suppliers typically accommodate requests for material declarations or testing reports. These documents demonstrate specific compliance concerning hazardous substances, often backed by lab results and safety reports to prove environmental responsibility, an aspect I prioritize when sourcing parts.

| Document Type | Information Provided | Purpose |

|---|---|---|

| Material Declaration | Detailed product composition | Verify absence of banned substances |

| Testing Reports | Laboratory analysis results | Confirm material safety |

Material declarations detail product composition, emphasizing the absence of prohibited substances as per regulations like RoHS and REACH. Suppliers provide third-party testing reports 8, often from certified labs, validating compliance through rigorous analysis. They ensure materials within products adhere to safety standards, vital for products entering environmentally regulated markets.

An essential aspect is a supplier’s capacity to conduct material analysis promptly, addressing requests without delays. Complex supply chains necessitate transparency and documentation accuracy, empowering suppliers to meet customer demands and regulatory changes continually. Large brands often possess dedicated teams for compliance, streamlining documentation requests efficiently. However, smaller suppliers may offer less comprehensive documentation, necessitating customer validation for efficacy.

Do you have statements for US-specific rules like California Proposition 65?

Proposition 65 aims to reduce exposure to harmful chemicals in California, a standard affecting products sold within the US state. Understanding a supplier’s compliance with such regulations ensures alignment with legally mandated safety protocols.

Suppliers often provide compliance statements for Proposition 65 upon request. These documents ensure products do not pose health risks associated with harmful substances under California law, reflecting thorough environmental responsibility for market access.

| Compliance Requirement | Targeted Substances | Required Documentation |

|---|---|---|

| Proposition 65 | Cancer-causing and reproductive toxins | Risk assessment and warning labels |

California Proposition 65 mandates disclosure of chemicals known to cause cancer or reproductive harm 9 in products. Suppliers create risk assessment documents, evaluating substances within parts for compliance. Documentation often includes testing reports, verifying standards through certified evaluations, ensuring products adhere to stipulated limits.

Large suppliers offer detailed compliance documents, including warnings and appropriate material labeling per Proposition 65. They conduct routine audits and safety assessments, maintaining adherence to evolving regulations. Suppliers need proactive measures for compliance document updates, addressing regulatory additions effectively. Transparency within product composition fosters trust, reassuring buyers of product integrity.

What is your process for managing and updating these compliance documents?

Compliance document management is key for maintaining regulatory alignment, necessitating an organized approach to ensure adherence to evolving standards. A supplier’s capability to manage documentation effectively offers confidence in their sustained environmental compliance.

Suppliers typically maintain systematic processes for managing compliance documents. They uplift environmental standards through regular updates, addressing regulatory changes effectively, ensuring alignment with global sustainability directives, which reassures me as a responsible buyer.

| Process Aspect | Description |

|---|---|

| Tracking System | Comprehensive documentation management |

| ISO 9001 Integration | Quality management coordination for compliance |

| Regular Updates | Continuous monitoring of regulatory changes |

Document management involves comprehensive tracking systems, ensuring suppliers meet environmental standards consistently. Suppliers update certifications and declarations to reflect regulation changes, necessitating constant vigilance towards SVHCs and new substances in RoHS directives. Maintaining an efficient document management system requires transparent communication channels and adept tracking capabilities.

Large suppliers incorporate compliance tracking within quality management systems like ISO 9001 10, ensuring coverage across multiple regulatory frameworks. Smaller suppliers may initially lack expertise but can manage updates through collaboration with manufacturers, addressing demands for contemporary documentation standards. Suppliers with robust management systems offer timely response to documentation needs, minimizing delays and sustaining buyer confidence.

Conclusion

Environmental compliance documents assure responsible sourcing, vital for regulatory adherence. Thorough documentation processes signify a supplier’s commitment to environmental responsibility, fostering trust and confidence. By addressing compliance thoroughly, suppliers fortify their position in regulated markets.

Footnotes

1. Defines what undercarriage parts for excavators & bulldozer are in heavy machinery. ↩︎

2. Legal risks associated with non-compliance. ↩︎

3. Overview of why hazardous materials are regulated. ↩︎

4. Official EU guide to the REACH regulation. ↩︎

5. What an MSDS is and what it contains. ↩︎

6. List of current SVHCs under REACH. ↩︎

7. The role of material verification in safety. ↩︎

8. Importance of independent lab verification. ↩︎

9. Official list of chemicals under Prop 65. ↩︎

10. How ISO 9001 integrates with compliance tracking. ↩︎