The complexity of managing large inventories often pushes me to seek innovative solutions. One such way is ensuring my supplier uses my SKU numbers and labels for easy integration and receiving efficiency. This step could drastically cut down errors and enhance warehouse operations.

Many undercarriage parts for excavators & bulldozer suppliers 1 can accommodate shipping using a client’s internal SKU numbers on box labels, which aids efficient inventory management. This customization aligns supplier shipments precisely with the client’s existing processes, minimizing discrepancies during the receiving phase.

Using internal SKU numbers 2 streamlines warehouse operations, saving time and reducing errors. Knowing this enhances confidence in your logistics approach, ensuring suppliers can deliver on these specifics smoothly.

Can your system print my SKU and barcode format on the individual box labels?

Having suppliers print custom SKUs and barcodes 3 saves significant time in receiving processes. Ensuring system compatibility and error-free integration makes my operations streamlined.

Suppliers who offer custom labeling are typically equipped to print client SKUs and barcodes directly on product box labels. This increases compatibility with warehouse processes and personnel accustomed to specific coding formats.

Barcode and Label Customization Benefits

Customizations reduce errors and help inventory personnel easily integrate new stock:

-

Accuracy in Inventory: Custom barcodes align precisely with warehouse management systems (WMS) 4, speeding up checks and balances.

-

Ease of Identification: Quick retrieval using scanned codes minimizes manual sorting, promoting efficiency.

Implementation Overview

| Element | Implementation Benefit |

|---|---|

| SKU Integration | Eliminates manual reconciliation errors |

| Barcode Format Alignment | Accelerates receiving, leading to efficient stocking |

| Custom Labeling Procedures | Enhances visibility and traceability |

Custom labeling ensures an efficient workflow by aligning inventory codes with existing systems. This reduces complexities during stock acceptance and dispatching.

Will the packing list match my PO line items and SKUs exactly?

Ensuring packing lists 5 align with purchase orders is a fundamental requirement. This accuracy aids in reducing discrepancies during warehouse intake and matches items precisely to order specifications.

A supplier can ensure that packing lists match your PO line items and SKUs exactly, avoiding any mismatch that could lead to inefficiencies. This requires synchronized systems and meticulous attention to detail in logistics operations.

Importance of Accurate Packing Lists

Packing lists that align with PO specifications mitigate various pitfalls:

- Precise Stocking: Itemized packing lists streamline inventory checks, ensuring stock quantities are verifiable from order to shelf.

- Mismatch Reduction: Proper alignment avoids miscommunication or potential conflicts in item counting or allocation.

Synchronization Benefits

Utilizing systems that synchronize packing lists and PO line items offers these advantages:

| Feature | Advantage |

|---|---|

| Accurate Item Counting | Reduces potential discrepancies significantly |

| Enhanced Stock Integrity | Maintains uniformity across inventory records |

| Workflow Simplification | Simplifies receiving processes deeply |

The intersection of precise packing lists with SKUs fortifies workflow efficiency, providing assurance that each step adheres rigorously to ordered specifications.

How does this help me reduce receiving errors in my warehouse?

Receiving errors can be costly and disruptive. Integrating streamlined processes ensures my warehouse operates smoothly and goods align perfectly with inventory system expectations.

Implementing SKU and PO line checks significantly reduces receiving errors by aligning items seamlessly with warehouse systems. This enforced accuracy ensures synchronization and stricter compliance with standardized inventory protocols.

Error Reduction Strategies

Using effective practices to minimize errors results in improved operational success:

- Data Accuracy: Accurate SKUs and barcodes eliminate guesswork, preventing erroneous database inputs.

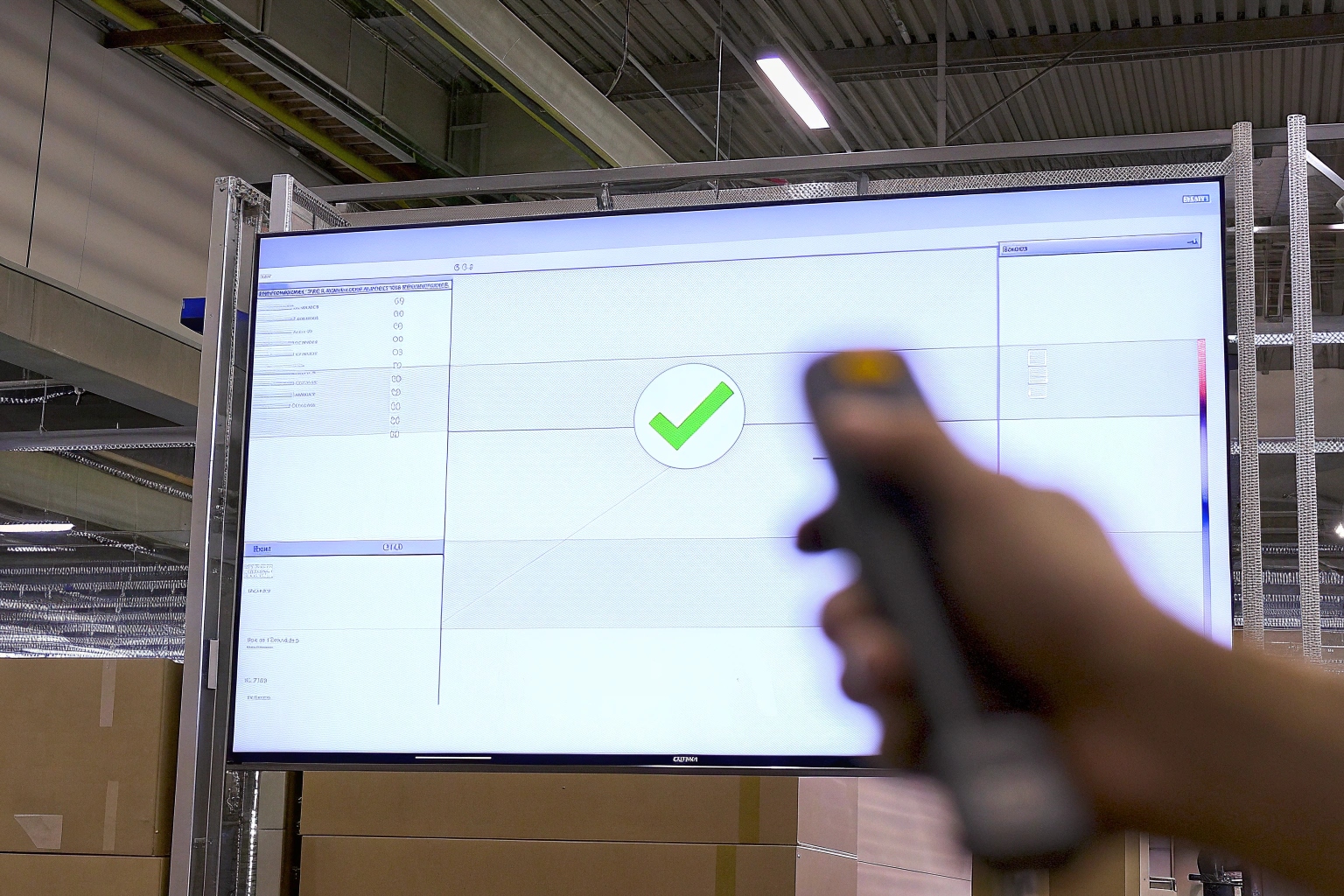

- Automation: Faster processing with barcode scanning tools 6 automates pathways for verification and stocking within warehouse systems.

Streamlined Process Overview

| Strategy | Effect |

|---|---|

| Data Synchronization | Aligns purchase data swiftly with stock entries |

| Efficient Scanning Practices | Hastens verification, saving labor resources |

Reducing errors not only emphasizes efficiency but solidifies client trust in logistics processes. This assurance strengthens confidence in long-term warehouse operations management.

Can you provide an Advance Ship Notice (ASN) file that I can upload to my WMS?

ASNs 7 are central to maintaining efficient operations. Real-time notifications help to anticipate shipments accurately, ensuring optimal preparedness in my warehouse.

Suppliers often provide an ASN file, facilitating real-time insight into incoming shipments. This document, when integrated into a Warehouse Management System (WMS), allows systematic updates and advance preparation for incoming stock.

Advantages of ASN Integration

ASN incorporation into warehouse systems allows better control over operations:

- Anticipatory Planning: Real-time shipment data leads to informed stocking decisions, enhancing preparedness.

- Operational Clarity: Clarifies item whereabouts, resulting in smoother transitions from docking to dispatching.

ASN files offer concrete benefits:

| Benefit | Description |

|---|---|

| Enhanced Visibility | Clear insights into stock transit |

| Inventory Management Improvement | Accurate stock forecasting and allocation |

ASN data fortifies warehouse systems through proactive management, improving efficiency, and bolstering resource allocation.

Conclusion

Shipping undercarriage parts for excavators & bulldozer with customized labeling streamlines warehouse operations, minimizing errors and boosting efficiency significantly.

Footnotes

1. How undercarriage parts for excavators & bulldozer suppliers can customize shipments. ↩︎

2. Benefits of using internal SKUs for inventory management. ↩︎

3. Importance of custom SKUs and barcodes in logistics. ↩︎

4. How WMS benefits from barcode alignment. ↩︎

5. Importance of synchronization in packing lists. ↩︎

6. Impact of barcode scanning tools on warehouse verification. ↩︎

7. Significance of ASNs in warehousing logistics. ↩︎