Undercarriage parts’ performance is highly influenced by heat treatment processes 1. These techniques ensure components have a hard, wear-resistant surface and a tough, impact-resistant core. In China, manufacturers employ sophisticated heat treatment methods to deliver excellence across track chains, rollers, sprockets, and idlers.

I know you’re eager to understand how we refine and balance hardness for surface, core, and Effective Hardness Depth (EHD) components in our parts.

Commonly, we use quenching and tempering 2 processes to prepare parts, inducing toughness and reducing brittleness. Induction hardening 3 further enhances surface hardness on critical wear areas like roller paths and sprocket teeth.

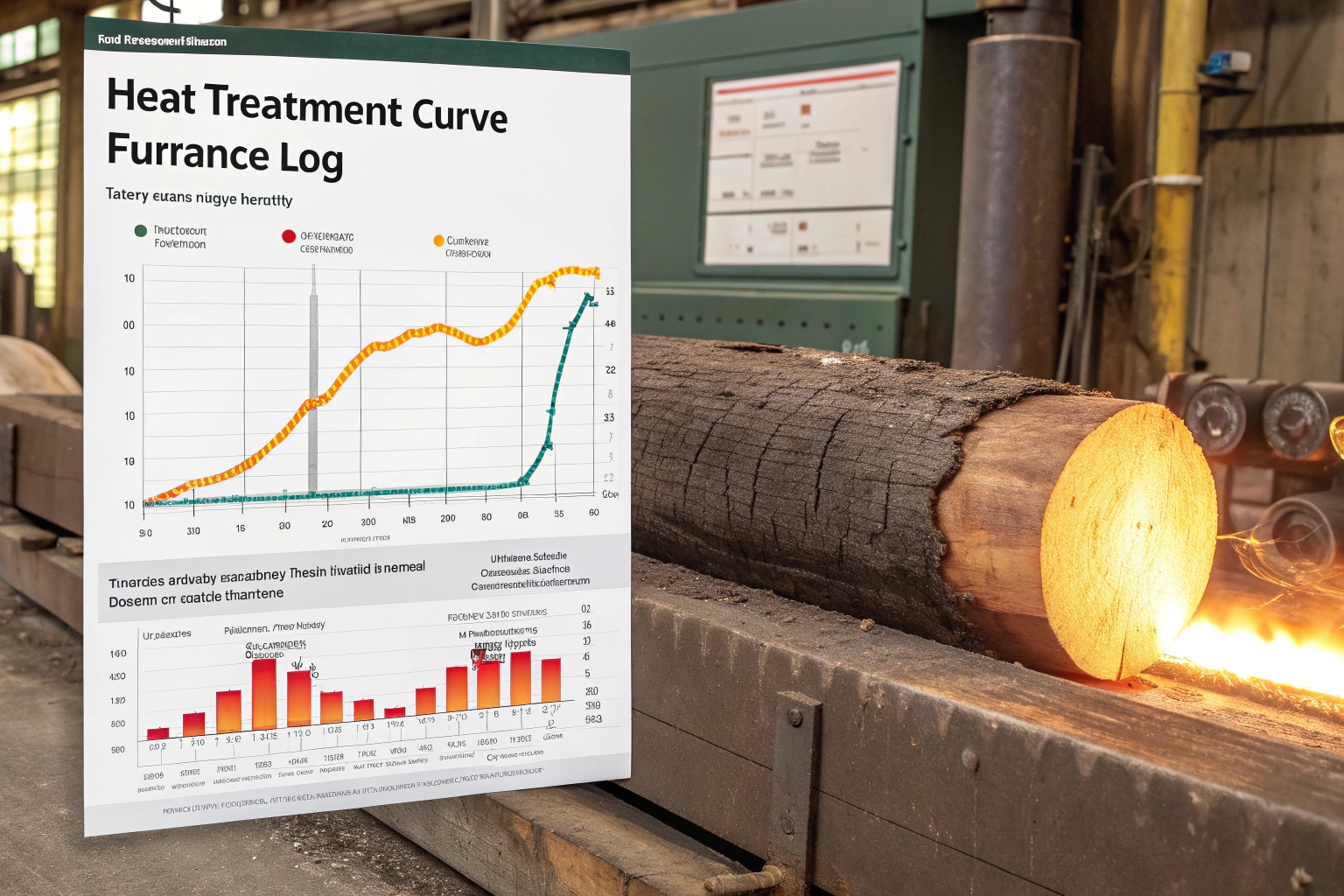

Will You Provide the Heat Treatment Curve and Furnace Log with the Shipment?

Providing a heat treatment curve and furnace log assures transparency in the processes undertaken. It may be integral to verifying compliance with specified hardness ranges and procedures.

I ensure each shipment includes comprehensive documentation detailing temperatures, time, and procedural specifics, confirming the applied heat treatments align with agreed specifications.

Exploring this transparency further, I will clarify how these documents inform your understanding of component preparation.

Documentation in Shipments

| Document Type | Description | Benefit |

|---|---|---|

| Heat Treatment Curve | Graphical representation of temperature changes | Validates treatment process |

| Furnace Log | Detailed record of heating cycles | Ensures standards compliance |

These documents offer insight into the precise conditions under which parts were treated, verified through proper documentation.

Receiving this information addresses your need for assurance regarding heat treatment efficacy and material integrity, asserting quality control.

Can I Set My Own Hardness Window and Effective Hardened Depth Targets?

Customization in heat treatment processes can tailor components to meet specific operational needs. Your requirements might necessitate alternative hardening specifics based on unique conditions.

Indeed, flexibility and adaptability in our processes allow you to set hardness and depth targets. This ensures parts withstand environmental and operational stresses specific to your applications.

Discussing customized hardening techniques strengthens your confidence in our capabilities to deliver precisely tailored options.

Custom Hardness Specifications

| Feature | Customizable Ranges | Benefit |

|---|---|---|

| Hardness Window | Surface: HRC 50-60, Core: HRC 24-34 | Aligns with operation stress |

| Effective Hard Layer Depth | EHD: 2-10 mm | Tailors wear resistance |

Customized processes can significantly impact reliability, longevity, and performance for components in varied environments and conditions.

Adapting to specific demands ensures your parts maintain optimal performance across different application settings.

Do You Run Induction Hardening and Quench-Temper for Rings and Rollers?

These advanced hardening techniques are pivotal for achieving the necessary part surface hardness and resilience. Induction hardening and quench-temper processes are widely applied.

For rings and rollers, we utilize these methods extensively to enhance wear resistance, ensuring high durability and operational life.

Look deeper into how we leverage these treatments to optimize your components’ structural and functional properties.

Heat Treatment Implementation

| Technique | Application Area | Outcome |

|---|---|---|

| Induction Hardening | Roller paths, sprocket teeth | Increases surface hardness |

| Quench-Temper | Entire component structure | Balances toughness and hardness |

Advanced techniques applied to rings and rollers optimize their wear resistance, assuring reliability and durability.

Combining these processes ensures your undercarriage parts achieve the structural integrity necessary to withstand challenging environments.

How Do You Calibrate Hardness Testers and Verify Repeatability?

To ensure consistent and accurate measurements, hardness testers must be calibrated and repeatability verified. Your concern may relate to this procedure’s precision and reliability.

Calibrating testers involves standardized processes that ensure continued accuracy and reliability. Our quality assurance protocols underscore this commitment to consistency across batches.

Dive deeper into our calibration practices to understand how they support predictable, accurate hardness readings.

Testing Protocols

| Calibration Method | Description | Ensured Outcome |

|---|---|---|

| Regular Calibration | Scheduled verification against standards | Ensures accurate readings |

| Repeatability Tests | Regular checks across samples | Confirms consistent results |

These quality assurance measures reinforce the assurance of producing consistently reliable undercarriage parts built to withstand their applications’ rigors.

Regular calibration ensures accuracy, fostering confidence in the parts’ and testing equipment’s abilities to meet your requirements.

Conclusion

Optimized heat treatment processes ensure undercarriage parts offer superior performance, and flexibility in treatment standards assists in meeting specific operational demands.

Footnotes

1. Overview of heat treatment in manufacturing. ↩︎

2. Quenching and tempering processes explained. ↩︎

3. Benefits of induction hardening for parts. ↩︎