Keeping track of all the different materials for your undercarriage parts for excavators & bulldozer can be confusing. I remember facing the same problem, trying to choose the right material that fits both quality and cost.

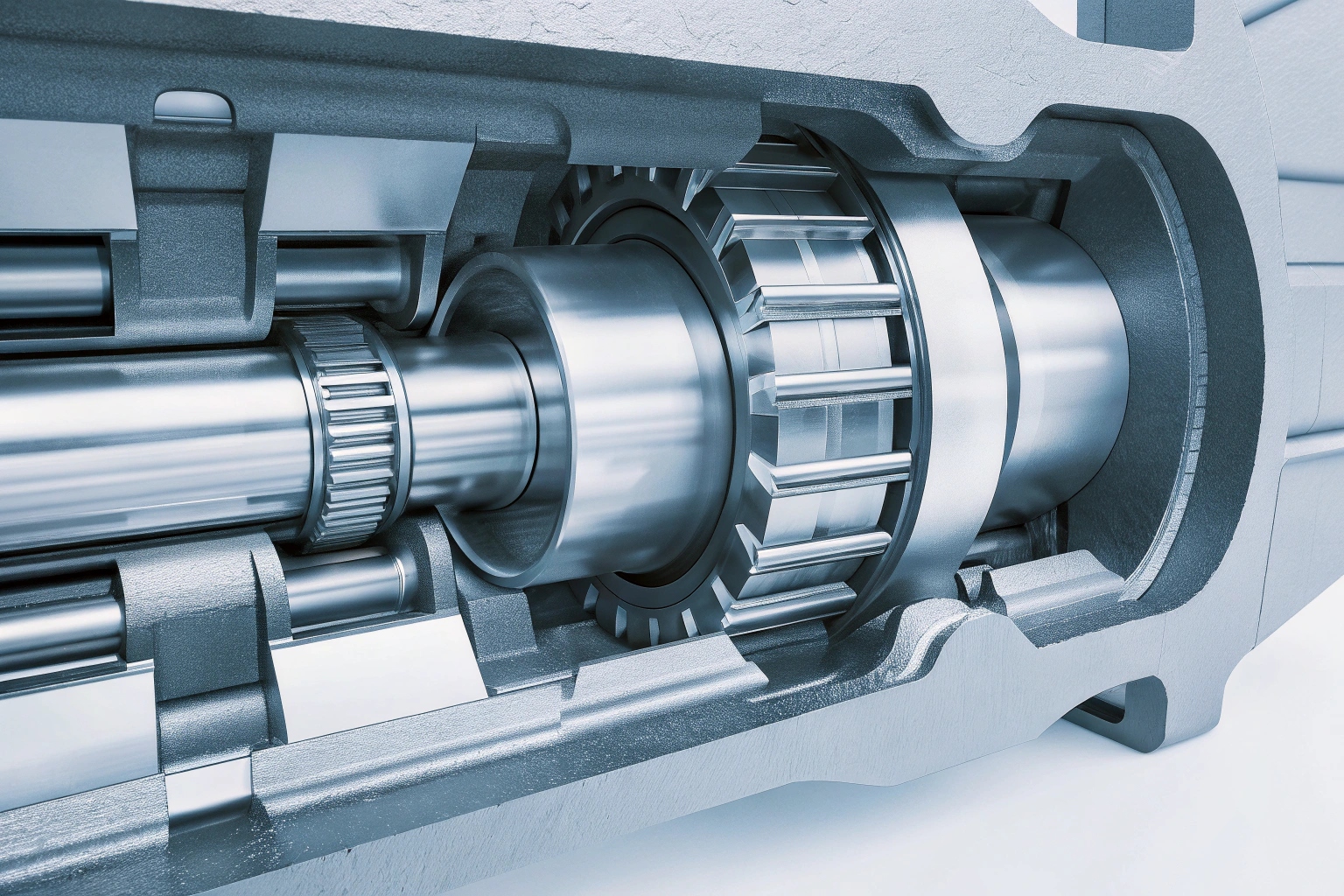

The housing and shaft materials for undercarriage parts for excavators & bulldozer are crucial for ensuring durability and performance. High-grade steel and heat-treated alloy steels 1 are commonly used, paired with appropriate seals and bearings to cater to various conditions.

Rollers and carrier rollers endure rigorous operations, demanding top-tier materials. Let’s uncover what sets them apart.

Can You Show Bearing Supplier Certificates and Dynamic Load Ratings?

Finding reliable suppliers and verifying load ratings can feel like navigating a maze. I know from experience that having the right certifications 2 makes a big difference.

Yes, bearing supplier certificates and dynamic load ratings 3 are essential parts of the quality assurance process to ensure the robustness and longevity of undercarriage parts for excavators & bulldozer. Detailed documentation reassures clients of compliance with required standards.

For example, verifying the certifications of our suppliers assures us that bearings meet industry standards for safety and performance. Additionally, dynamic load ratings provide insight into how the bearings will perform under stress.

Dynamic Load Ratings Explained

- Definition: Measures the ability of a bearing to endure varying loads without failure.

- Importance: Helps in selecting the right bearing type for specific industrial applications.

- Supplier Certificates: Ensure products meet premium standards.

Verifying these factors ensures that your undercarriage parts for excavators & bulldozer can withstand environmental pressures, enhancing the overall functionality of your machines. Such transparency strengthens trustworthiness and minimizes failures.

Heat treatment specs and core profiles are as vital as they are technical. I remember frequently consulting with technical experts 4 to demystify these specifications.

Yes, sharing shaft heat treatment specifications and case/core profiles is pivotal. They define the strength and endurance needed to withstand operations’ harshness. These specs also determine the optimal functionality and life span of undercarriage components.

For instance, the heat treatment of shafts involves multiple processes, ranging from quenching to tempering, achieving a surface hardness between HRC 52-58 5. This specificity ensures the shaft resists wear and tear during its service life.

Heat Treatment Process

- Quenching: Rapid cooling to increase hardness, benefiting material durability.

- Tempering: Adjusts hardness for increased toughness.

- Case/Core Profiles: Balances external hardness with internal resilience, maintaining component integrity even under high stress.

By sharing such precise metrics, trust is built between suppliers and purchasers, ensuring materials are tailored to particular industrial requirements.

Can I Select Double-lip vs Labyrinth Sealing Based on My Mud Conditions?

Choosing the correct seal can safeguard your equipment’s life. I’ve learned through numerous projects how integral this selection is.

Yes, selecting between double-lip 6 and labyrinth seals 7 based on environmental conditions, like mud, ensures optimal sealing efficiency and part longevity. Each seal offers distinct advantages suitable for specific exposure scenarios.

Frequently, I compared different sealing solutions to align with the prevailing environmental conditions, thus preventing equipment breakdowns and reducing maintenance costs.

Seal Comparison Table

| Seal Type | Advantages | Ideal Conditions |

|---|---|---|

| Double-lip | Excellent for deep mud and water exclusion. Provides robust contamination barrier. | Wet and muddy environments |

| Labyrinth | High tolerance to high-temperature conditions and abrasive environments. | Dry and dusty conditions |

The choice of seal type depends heavily on its operating environment. Making the right choice enhances operational efficiency, extends service life, and limits maintenance overheads.

Do You Offer Heavy-duty Roller Designs for My Mining Applications?

Mining applications are as demanding as they are dynamic. Working closely with various industries, I’ve seen how critical robust rollers are in handling such tough jobs.

Yes, heavy-duty roller designs 8 cater specifically to the rigorous demands of mining applications, ensuring durability under pressure with robust materials and engineered designs.

In field conditions, heavy-duty rollers must bear constant wear from harsh substrates. Design enhancements like reinforced housing and advanced bearing types withstand these conditions.

Design Features of Heavy-Duty Rollers

- Reinforced Housing: Durable material use like high-strength steel 9 ensures structural integrity.

- Advanced Bearings: Utilization of spherical and cylindrical bearings for high load capacity and alignment.

- Effective Seals: Incorporation of mechanical face seals 10 for contamination suppression and internal lubrication retention.

Through diversified experiences, I’ve learned that selecting the right roller design affects operational outcomes dramatically, promoting long-term economic efficiency and minimizing downtime.

Conclusion

The choice of materials and technologies for undercarriage parts for excavators & bulldozer profoundly influences their performance and durability in diverse operational environments.

Footnotes

1. Learn about heat-treated alloy steels for enhanced performance. ↩︎

2. Explore bearing supplier certifications for quality assurance. ↩︎

3. Understand dynamic load ratings for bearing selection. ↩︎

4. Consult technical experts for heat treatment specifications. ↩︎

5. Discover hardness scale specifics for shaft treatment. ↩︎

6. Examine double-lip seals for protective capabilities. ↩︎

7. Review the advantages of labyrinth seals. ↩︎

8. Investigate heavy-duty roller designs for mining. ↩︎

9. Insights into high-strength steel for structural integrity. ↩︎

10. Benefits of mechanical face seals in contamination control. ↩︎