You see it too often—a leaked roller causing downtime just weeks after installation, frustrating your customers and eating into your margins. I know that preventing this starts with the smallest details inside the component.

The right combination of FKM seals and Lithium Complex or Calcium Sulfonate grease is critical for high-temperature and muddy terrain. While NBR seals and standard lithium grease work for general use, upgrading materials prevents seal hardening and lubricant washout in severe environments.

We need to look past the steel and talk about the "soft" parts. The steel might last for years, but if the grease fails or the seal cracks, the entire unit becomes scrap metal. Let’s look at the technical specs to help you choose the right configuration for your specific market.

What grease viscosity and type suits my specific climate and duty?

I know that looking at a grease spec sheet can sometimes feel like reading a foreign language. But getting this wrong is the number one cause of bearing failure in our industry.

For hot climates, use a higher viscosity base oil (ISO VG 220-460) to maintain film thickness. In muddy conditions, Calcium Sulfonate thickeners offer superior water resistance compared to standard Lithium. Always match the NLGI grade (usually #2) to your operating temperature range.

When we talk about grease for undercarriage parts like track rollers and idlers, we are really talking about two things: the oil that does the lubricating and the thickener that holds that oil in place.

Understanding Base Oil Viscosity

Think of viscosity as the thickness of the oil film. In high-temperature regions, like mining sites in Australia or summers in Texas, the oil becomes thinner as it heats up. If you use a standard, low-viscosity grease, the protective film between the metal shaft and the bushing disappears. This leads to metal-on-metal contact, heat generation, and immediate failure. For these hot environments, I always recommend a base oil viscosity 1 of ISO VG 220 or even 460. Conversely, if your customers operate in freezing Canada, a lower viscosity allows the roller to turn freely without drag.

The Thickener: Lithium vs. Calcium Sulfonate

The thickener is like a sponge that holds the oil. For years, Lithium grease has been the standard. It is good, but it has a weakness: water. When an excavator is working in a swamp or deep mud, water can wash standard Lithium grease away.

This is where Calcium Sulfonate grease 2 changes the game. It has natural rust-inhibiting properties and, more importantly, it does not break down when mixed with water. It stays sticky and keeps the mud out. If your clients are complaining about "washout" or rollers running dry in wet conditions, switching the grease type is often a cheaper and faster fix than redesigning the mechanical seal.

Here is a quick comparison to help you decide:

| Feature | Standard Lithium Grease | Lithium Complex Grease | Calcium Sulfonate Grease |

|---|---|---|---|

| Heat Resistance | Good (up to 120°C) | Excellent (up to 160°C) | Excellent (up to 180°C) |

| Water Resistance | Fair (can wash out) | Good | Superior (best for mud) |

| Load Capacity | Medium | High | Very High |

| Best Use Case | General Construction | Heavy Duty / Mining | Wet / Swamp / Marine |

Should I use lithium complex grease for my rollers?

You might be asking if the extra cost for "Complex" grease is actually worth it for your distribution business. For heavy-duty mining clients, the answer is almost always yes.

Lithium Complex grease is superior to simple Lithium grease because it has a higher dropping point (260°C vs 190°C). This stability prevents the grease from turning into liquid and leaking past the seals when your undercarriage components get hot during long shifts.

To understand why this matters, we have to look at how a track roller creates heat. As the excavator travels, friction inside the bushing generates thermal energy. In a simple Lithium grease, once the temperature hits around 180°C (its dropping point 3), the soap structure collapses. The grease turns into a thin liquid, exactly like butter melting in a frying pan.

The "Bleed" Problem

Once the grease turns to liquid, it is very hard for the floating face seals 4 to keep it inside. The fluid pressure builds up, pushes past the O-rings, and leaks out. Once the oil leaks out, dirt gets in.

Why "Complex" Matters

Lithium Complex 5 grease is made with a different chemical bonding process. It stays solid and "grease-like" at much higher temperatures, often up to 260°C. It maintains its structure. This means that even if the roller gets incredibly hot due to friction or ambient temperature, the grease stays where it belongs—lubricating the shaft.

Cost vs. Benefit Analysis

For a distributor like you, David, the cost difference per roller is often less than a dollar. However, the perceived quality difference is massive. If you are selling to a customer who runs their machines 24 hours a day in a quarry, that standard grease will fail. By specifying Lithium Complex, you are essentially buying an insurance policy for your brand reputation.

Key Technical Differences:

- Shear Stability: Lithium Complex resists softening when it is "worked" or agitated constantly by the turning roller.

- Life Span: It oxidizes slower than simple lithium, meaning the grease lasts longer inside "sealed-for-life" components.

How do I check seal compatibility with my grease?

I have seen perfectly good rollers fail because the rubber seal reacted poorly with the oil or the heat. Choosing the right material is not just a detail; it is essential.

Choose NBR (Nitrile) for general construction and cold climates due to its excellent tear resistance and lower cost. Upgrade to FKM (Viton) for mining or high-heat applications, as it withstands temperatures up to 200°C and resists chemical degradation, though it costs more.

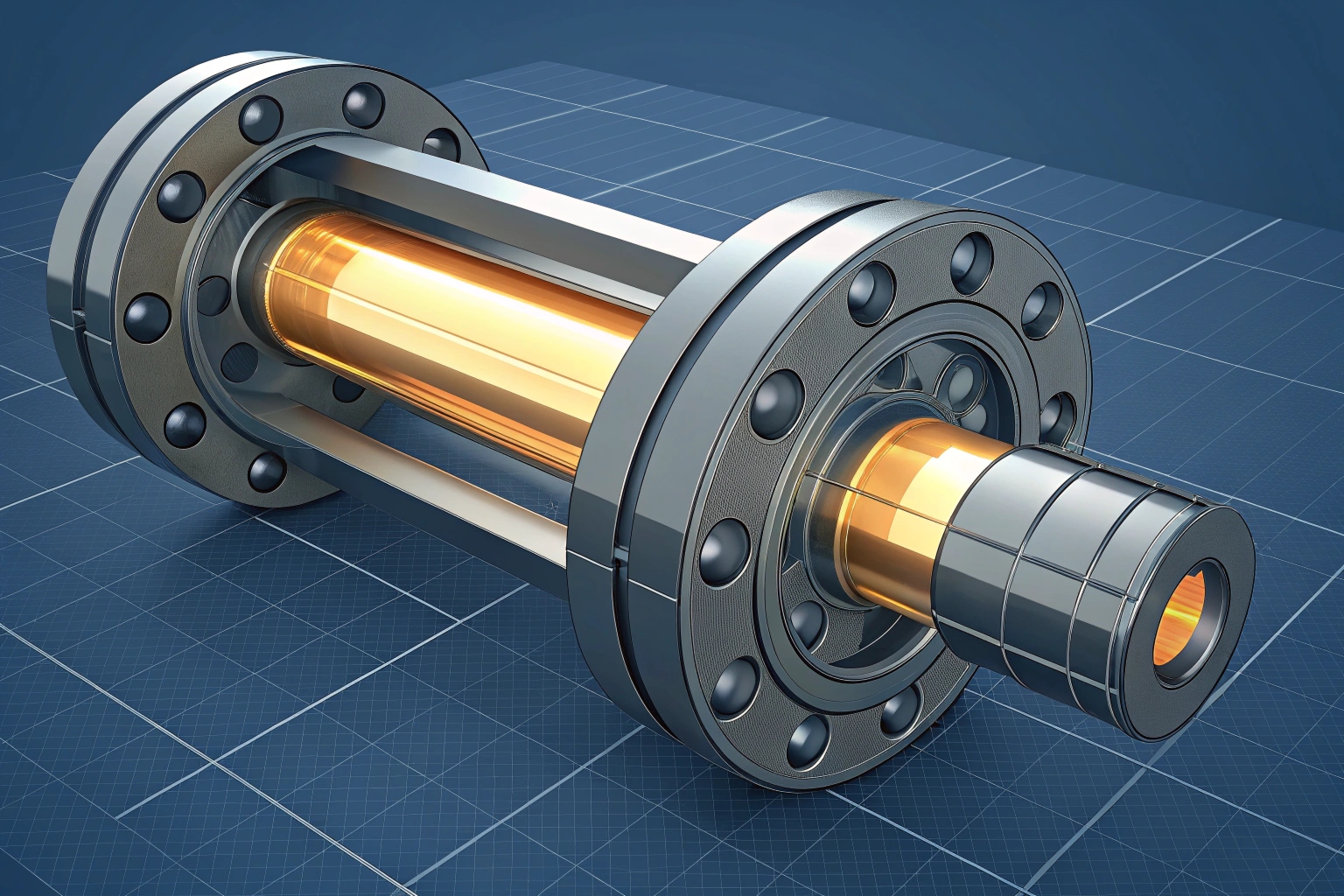

The "seal" in a track roller usually refers to the Floating Face Seal (or Duo-Cone seal). This system consists of two metal rings and two rubber O-rings (Toric rings). The rubber rings act as springs, pushing the metal faces together. If that rubber fails, the seal opens, and the roller dies.

NBR (Nitrile Butadiene Rubber)

Nitrile Butadiene Rubber 6 is the industry standard for a reason. It is tough. Physically, it resists tearing and abrasion very well. If your customers are working in standard construction sites where temperatures are moderate (-20°C to 100°C), NBR is the best choice.

- Pros: Excellent physical strength, good oil resistance, lower cost.

- Cons: It hardens and cracks if the temperature stays above 110°C for too long. It also degrades quickly if exposed to ozone or sunlight (though this is rare inside a roller).

FKM (Fluoroelastomer / Viton)

Fluoroelastomer 7 is the premium choice. It is chemically inert, meaning it barely reacts to anything.

- Pros: It handles heat up to 200°C without losing its elasticity. It is highly resistant to aggressive oil additives.

- Cons: It is physically weaker than NBR. It can tear easier during rough installation. It is also 3 to 5 times more expensive than NBR.

The Compatibility Check

You must ensure your grease base oil matches the seal. For example, some synthetic oils can cause NBR to swell and get soft. If the rubber swells, it creates too much pressure on the metal rings, causing them to burn out. If it shrinks, the oil leaks out.

| Property | NBR (Nitrile) | FKM (Viton) |

|---|---|---|

| Temperature Range | -40°C to +120°C | -20°C to +200°C |

| Oil Resistance | Good | Excellent |

| Abrasion/Tear Resistance | Excellent | Fair |

| Cost | Low | High |

| Compression Set (Heat) | Fair | Excellent |

My Recommendation for Your Market

For your premium line targeting mining customers, I suggest specifying FKM rings. The heat generated by heavy bulldozers and continuous mining excavators will cook NBR rings hard, causing them to lose their "spring" effect (compression set 8). FKM keeps pushing the metal rings together even after thousands of hours of heat.

Can my supplier pre-fill and test roller sealing?

Trusting a factory to assemble parts correctly is one thing, but verifying it with data is another. You need to know these parts will hold up before they ship.

A reliable supplier must perform 100% air-tightness or vacuum testing on track rollers after assembly. They should pre-fill the rollers with the specified lifetime oil or grease and provide test reports verifying that no leaks occurred under pressure.

You mentioned earlier that quality consistency is a pain point for you. The only way to solve this is through process control at the factory level. A roller is a "black box"—you cannot see inside it once it is assembled. Therefore, the testing process is your only guarantee.

The Vacuum Test (Air-Tightness)

Before we inject any oil, every single roller at Dingtai goes through a vacuum test 9. We suck the air out of the internal cavity and hold the vacuum for a specific time. If the pressure gauge moves, it means air is leaking back in.

- Why we do this: If air can get in, oil can get out. This test detects microscopic defects in the rubber O-rings or the metal floating seals that the human eye cannot see.

Pre-filling Considerations

Many suppliers ship rollers "dry" or with just a little assembly lube 10 to save on shipping weight and mess. I advise against this. You should ask your supplier to pre-fill the rollers with the exact volume of clean, filtered oil or grease required for the lifetime of the part.

- Contamination Control: If your customer fills the roller on the job site, they might introduce dust or use the wrong oil. Factory filling happens in a clean room environment.

- Ready-to-Install: It saves your customer labor time.

The "Running-In" Test

For high-end orders, we also perform a rotation test. We spin the roller at high speed to ensure the metal face seals settle into position properly. This is crucial because if the seals are slightly misaligned, they will leak immediately upon the first use.

Here is what you should demand from your supplier’s QA report:

1. Vacuum Decay Data: Proof that the seal held pressure.

2. Fill Volume Verification: Confirmation that the correct amount of lubricant was added (too much causes pressure blow-out; too little causes wear).

3. Torque Check: Verification that the plug and shaft are tightened to spec.

By controlling these inputs, we eliminate the "Monday morning" defects where human error causes a leak.

Conclusion

To guarantee performance, match FKM seals with Lithium Complex or Calcium Sulfonate grease for high-heat and muddy sites, while using rigorous factory vacuum testing to ensure reliability.

Footnotes

1. Importance of viscosity in lubrication film strength. ↩︎

2. Benefits of calcium sulfonate thickeners for high-load applications. ↩︎

3. Definition of the temperature where grease turns to liquid. ↩︎

4. How duo-cone seals prevent leaks in heavy machinery. ↩︎

5. Performance characteristics of lithium complex grease formulations. ↩︎

6. Properties and applications of NBR in industrial sealing. ↩︎

7. Advantages of FKM material for high-temperature resistance. ↩︎

8. Permanent deformation of rubber seals under heat and pressure. ↩︎

9. Explanation of vacuum decay testing for leak detection. ↩︎

10. Role of specialized lubricants during component assembly. ↩︎