When sourcing excavator undercarriage parts, verifying supplier legitimacy is crucial for ensuring quality and reliability. In my experience, thorough due diligence involves validating business registration 1, production capacity, certifications, and compliance.

Conducting supplier due diligence includes initial document reviews and progresses to on-site inspections, remote video assessments, or third-party evaluations via agencies like SGS 2. This layered approach ensures suppliers meet necessary standards in quality and operation.

Ensuring supplier legitimacy and capability is a multi-step process that saves time and mitigates future risks. Correctly identifying reliable suppliers is fundamental to establishing successful, long-term partnerships.

What audit checklist should I use for machining shops?

An audit checklist plays a critical role in evaluating machining shops. When assessing technical capabilities, we must focus on areas like material traceability 3, equipment calibration certificates, and quality control documentation.

An effective audit checklist for machining shops includes checking employee certifications, reviewing machinery maintenance logs, and inspecting production records for consistency. It’s important to systematically verify all operational aspects before proceeding to secure partnerships.

When visiting a machining shop, the checklist should prioritize examining CNC capabilities, heat-treatment procedures, and worker safety protocols. Make sure to review ISO certificates and cross-check these against official government databases.

Tables can clarify audit insights:

| Parameter | Checks | Documentation |

|---|---|---|

| Material Traceability | Verify batch identity | Material test reports |

| Equipment Calibration | Check calibration logs | Calibration certificates 4 |

| Safety Practices | Review compliance records | Safety protocol documents |

Applying structured audits can effectively gauge manufacturing capabilities before committing to large orders.

Can video audits replace first visits for my orders?

In some cases, video audits might offer a practical alternative to physical visits, especially when geography and time constraints come into play. They provide a real-time view and validation of standard procedures.

Video audits can replace initial visits by offering a virtual walkthrough of facilities, examining production lines, and assessing quality control measures. This option proves particularly useful during global supply chain disruptions 5.

However, while video audits provide convenient access, they should supplement rather than replace physical inspections for key suppliers. For strategic partnerships, maintaining direct engagement through in-person visits remains essential.

Video audits can determine initial compliance, but high-value or critical components like excavator undercarriage parts require thorough physical assessment for verifiable quality assurance.

Should I require 5S and lean practices evidence?

Requiring evidence of 5S and lean practices from suppliers is beneficial for optimizing operations. These methodologies foster efficient workflow, reduce waste, and maintain organised workplaces.

Requiring evidence of 5S and lean practices 6 involves checking visual management tools, workplace organization, and standard operating procedures. Lean practices should be demonstrated through efficiency metrics and continuous improvement logs.

Implementing these principles results in tangible improvements—including reduced lead times and enhanced product quality. Ensure suppliers adhere to lean standards as part of their operational strategy.

How do I validate CNC and heat-treatment capability?

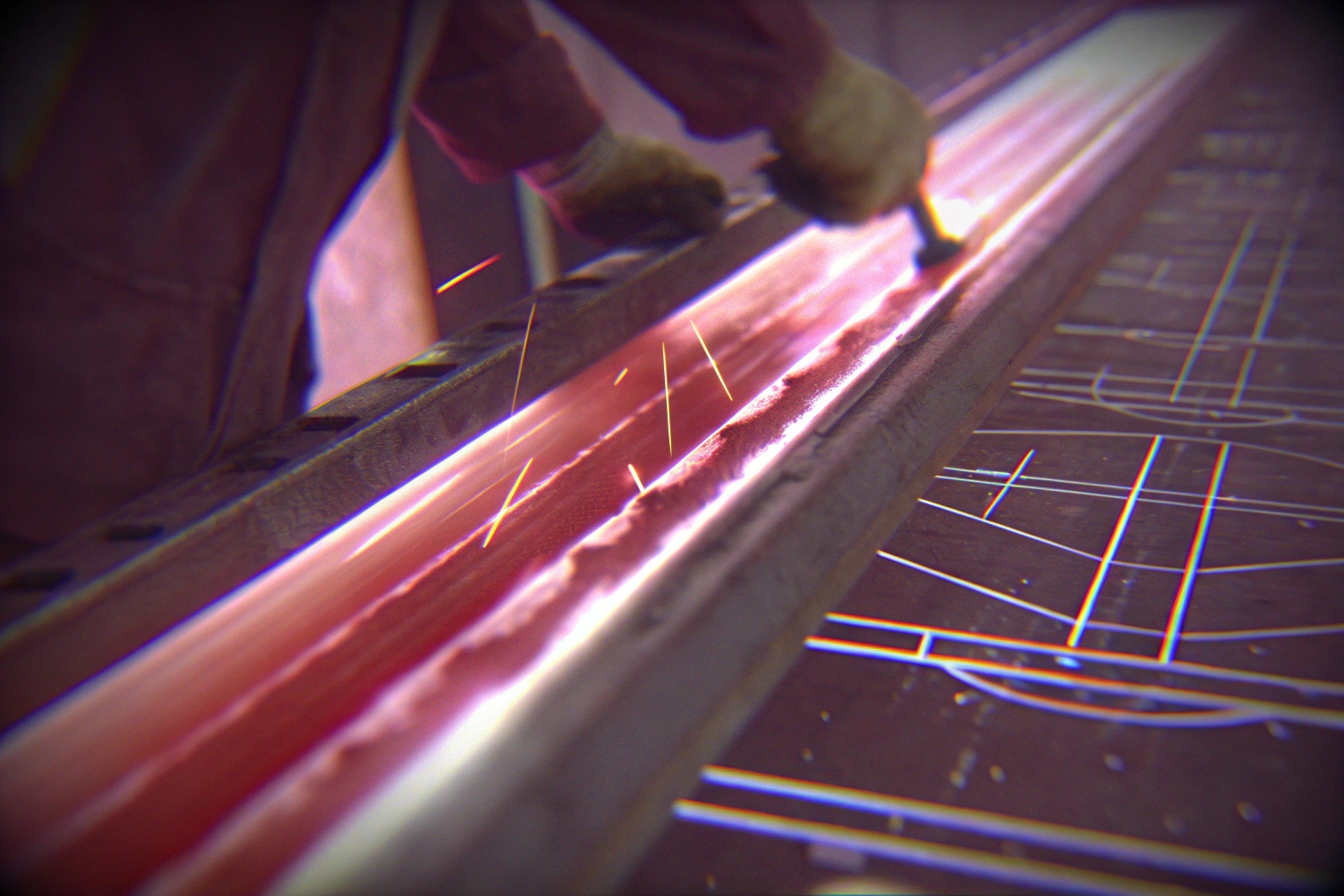

Validating CNC and heat-treatment capabilities requires precise scrutiny of technical specifications and procedural integrity. Key aspects include reviewing calibration records, burn-in tests, and thermal treatment logs.

Ensuring efficacy involves checking CNC capabilities 7, machining precision, and operator training certifications. Heat-treatment audits should focus on furnace calibration, hardness testing results, and heat-treatment procedures 8 process repeatability for parts like track chains.

Detailed assessments ensure component reliability, especially for excavator undercarriage parts. CNC and heat-treatment operations must comply with industry standards to consistently produce durable, high-quality components.

Conclusion

Conducting thorough supplier audits and due diligence is vital for ensuring high-quality excavator undercarriage parts. A blend of on-site, remote, and third-party evaluations can help verify standards, resulting in reliable, long-term supplier relationships.

Footnotes

1. Importance of validating company legitimacy and legal standing. ↩︎

2. Overview of SGS inspection, verification, and testing services. ↩︎

3. Understanding how materials are tracked throughout manufacturing. ↩︎

4. Standards for maintaining measurement accuracy in industrial equipment. ↩︎

5. Analysis of how global events impact logistics networks. ↩︎

6. Guide to waste reduction and efficiency in manufacturing. ↩︎

7. Explanation of Computer Numerical Control machining potential. ↩︎

8. Industrial processes for hardening and altering metal properties. ↩︎

9. Definition and benefits of Original Equipment Manufacturers. ↩︎

10. Distinguishing between quality assurance and quality control. ↩︎