Performance inconsistency can lead to frustrating downtime and dissatisfied customers. As someone committed to quality, I’ve often pondered the steps required to ensure every batch of my excavator undercarriage parts meets the expected standards.

To prevent performance inconsistency across batches of excavator undercarriage parts, it’s essential to implement stringent quality control measures 1. This includes defining uniform technical standards, locking in core supply chains, and demanding batch-level traceability 2. Regular calibration, batch-level testing, and documented consistency measures can help foresee and mitigate variability.

By understanding root causes through rigorous QC processes 3, monitoring environmental conditions, worker training, and supplier reliability 4, performance inconsistency can be dramatically reduced. Additionally, predictive tools can anticipate issues before they affect production outcomes.

Can I require batch-level hardness and dimension data?

Effective quality control starts with accurate and detailed batch-level data 5. Without these records, achieving consistent product performance seems almost impossible.

Requiring batch-level hardness and dimension data can significantly enhance quality assurance processes 6 for excavator undercarriage parts. This data should be included in each shipment to ensure consistent adherence to specifications, boosting product integrity and customer trust.

Surface hardness, tensile strength, and dimensional tolerance are key parameters. Ideally, obtain measurements from different sections of the parts to ensure uniformity. Supplier documentation should include metallurgy certificates 7 and dimensional reports that can be cross-checked against specified standards.

Key Parameters in Material Data

| Parameter | Importance | Acceptable Range (Example) |

|---|---|---|

| Hardness | Determines wear resistance | HRC50-58 |

| Dimension | Ensures proper fit and compatibility | ±0.1mm |

| Material Grade | Affects durability and performance | Verified metallurgy standards |

Regular reviews of these data empower you to pinpoint any deviations or drift in performance early. Supplier inspections and batch testing must align with standardized quality metrics 8 to prevent frequent discrepancies.

Do I need SPC charts to monitor process variation?

Monitoring variation without proper tools can lead to unexpected defects and lost efforts. Putting an invisible watchdog on production helps foresee potential challenges.

Implementing Statistical Process Control 9 (SPC) charts is crucial to systematically track and control production variations in excavator undercarriage parts. These charts help in identifying trends, outliers, and process shifts that might lead to quality issues.

SPC charts utilize data-driven approaches to visualize production variations, offering insights into setup errors or process drift. When combined with regular audits, SPC charts serve as a preventive measure, aiming to reduce variations in material properties and machining dimensions.

Benefits of SPC in Quality Control

- Real-Time Monitoring: Quickly identifies shifts in process conditions.

- Report Generation: Assists in creating detailed documentation of process behavior over time.

- Training Tool: Helps operators understand and follow best practices by visualizing effects of deviations.

By establishing robust process controls using SPC, you leverage statistical data to maintain controlled production variations, ultimately reducing inconsistency risks.

How do I enforce material lot traceability in my PO?

Lack of component traceability can stall operational efficiency. As materials flow through production, tracking their path ensures accountability.

Enforcing material lot traceability 10 in purchase orders is vital to ascertain quality consistency for excavator undercarriage parts production. Unique identifiers on materials—such as batch numbers—help connect the dots between quality assurance data and specific production lots.

To enforce traceability, ensure that all orders mandate the inclusion of detailed certificates and batch recordings. Furnish processes with automated tools to cross-reference traces against desired material properties and ensure rigorous checks.

Traceability System Essentials

| Step | Description |

|---|---|

| Unique ID Coding | Assign unique codes to each material batch |

| Cross-Verification | Match codes with batch certificates and QC data |

| Documentation | Record processing conditions tied to prescribed specs |

Integrating traceability in every production phase avoids mishaps from uncertainty, offering proactive mechanisms to manage quality control.

Should I run periodic third-party lab tests?

In-house tests limit perspectives and invite biases. Seeking unbiased and thorough validation requires looking beyond the factory walls.

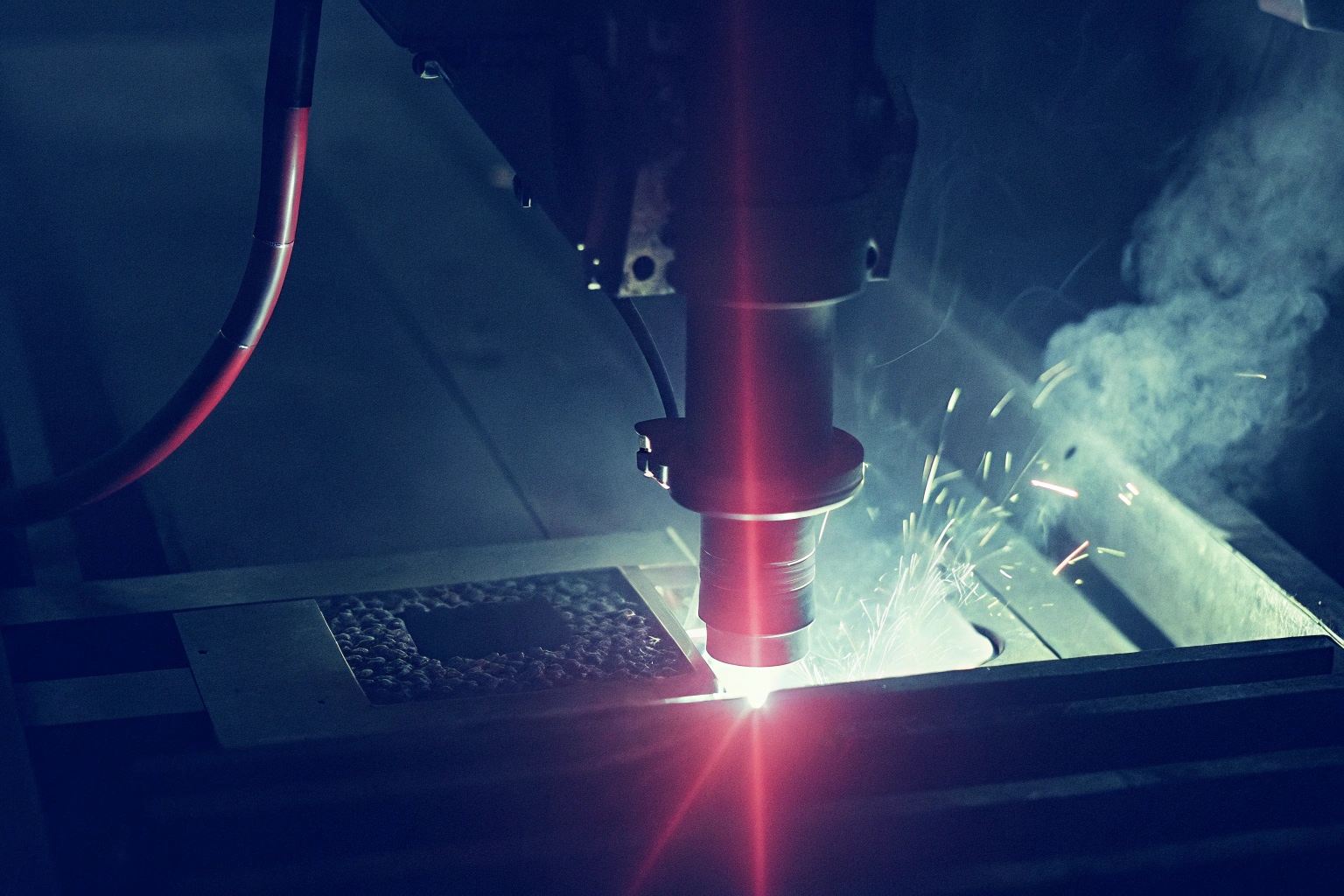

Running periodic third-party lab tests 11 complements your existing quality control measures by providing independent verification of material properties and process compliance.

Third-party testing offers an unbiased assessment of your excavator undercarriage parts through expert analysis and comparison against industry standards. These tests can reveal hidden inconsistencies in critical attributes such as metal composition, surface properties, and mechanical strengths.

Advantages of Third-Party Testing

- Unbiased Evaluation: Third parties provide a fresh, objective view of material quality.

- Validation: Confirms internal QC results align with broader industry standards.

- Expert Insight: Offers deeper understanding of potential quality challenges and solutions.

Third-party tests act as essential checkpoints within your quality assurance lifecycle, fortifying consistency measures with expertise-driven oversight.

Conclusion

Preventing performance inconsistency across batches involves harmonizing rigorous quality controls, batch-level insights, and meticulous traceability, reinforced by external evaluations. Each measure acts as a safeguard against variabilities, aligning manual and automated precision for reliable output.

Footnotes

1. Discover stringent quality control measures for manufacturing success. ↩︎

2. Importance of traceability in maintaining consistent batch quality. ↩︎

3. Explore comprehensive QC process strategies. ↩︎

4. Enhance supplier reliability to prevent inconsistencies. ↩︎

5. Benefits of batch-level data for quality control. ↩︎

6. Methods for boosting quality assurance processes. ↩︎

7. Importance of metallurgy certificates in quality checks. ↩︎

8. Align quality metrics to prevent discrepancies. ↩︎

9. How SPC charts aid in monitoring production variations. ↩︎

10. Techniques for enforcing material traceability. ↩︎

11. Benefits of third-party lab tests in quality assurance. ↩︎