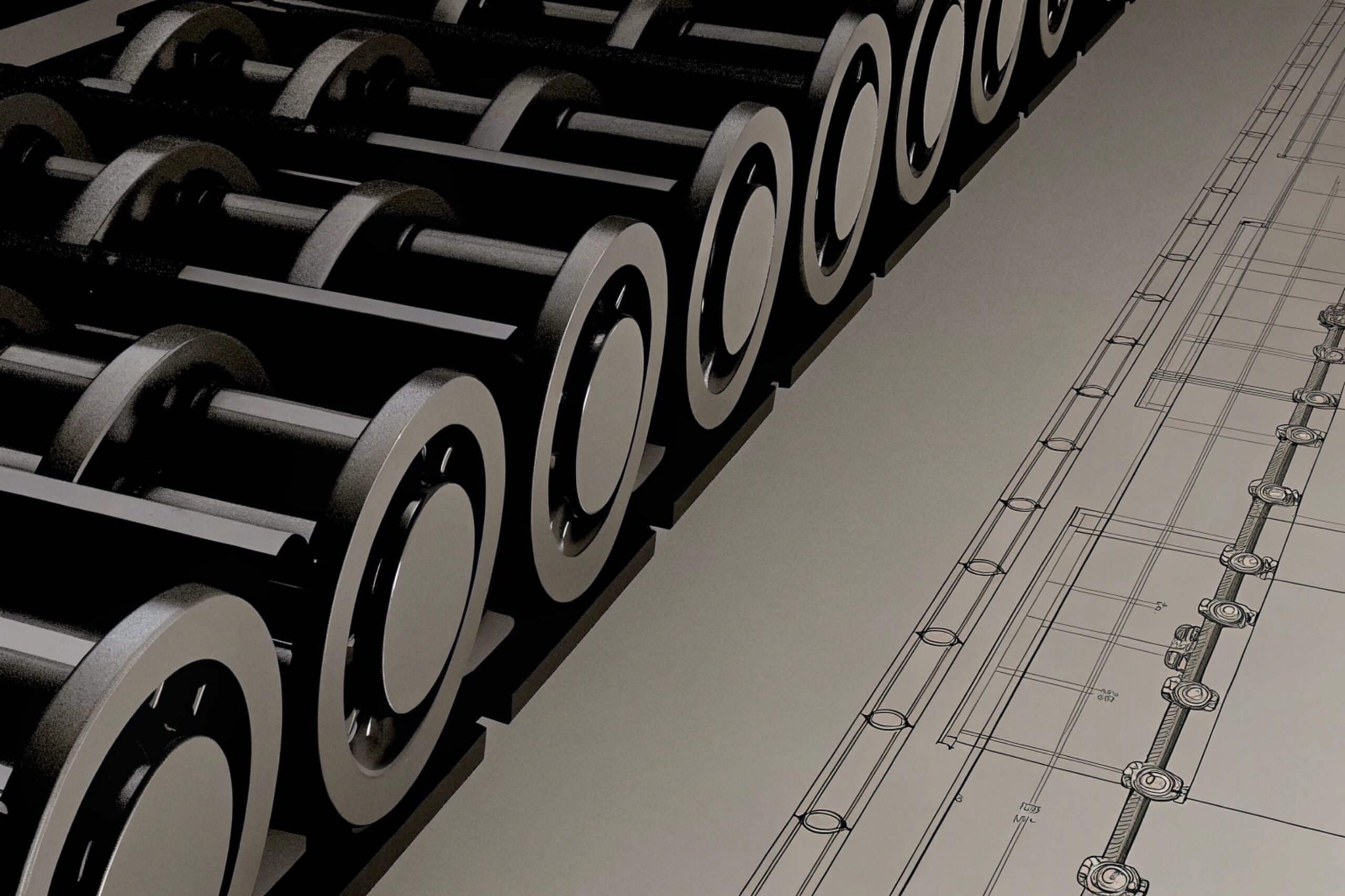

Selecting the right track tension cylinder 1 and recoil spring 2 for my excavator can be daunting due to the numerous specifications and compatibility requirements involved. It’s crucial to ensure the parts fit well with my machine model to enhance performance and longevity.

To select the appropriate track tension cylinder and recoil spring, begin by confirming your excavator’s make and model specifications. Check details like cylinder diameter, spring length, and operating environment compatibility. This ensures the components match the machine’s needs for optimal performance and safety.

Selecting the right parts is vital for preventing tension failures and ensuring smooth operation. Let me walk you through the important considerations, from compatibility to material durability, and explain what makes a reliable product choice.

What stroke and bore specs fit my machine model?

A wrong fit could spell disaster for my excavator’s undercarriage 3. It’s essential to get the stroke and bore specs right to keep things running smoothly and chill.

Select stroke and bore specs that exactly match your excavator’s model. This involves considering dimensions such as cylinder diameter and spring length, which should align with manufacturer’s specifications to fit the machine correctly.

Choosing the right track tension cylinder with the correct stroke and bore specs involves understanding the detailed dimensions that fit your machine model. Start with the cylinder diameter 4, often recommended to be between 60-125mm, depending on the machine’s tonnage. Cylinder diameters between 60-80mm are typical for small excavators (5-10 tons), while 80-125mm would be for larger ones. Rod diameter is also crucial, ranging from 35-70mm. Moreover, consider the stroke length for each excavator weight class—small machines needing 100-150mm, medium 150-200mm, and large 200-300mm. The push force from these cylinders should align with the machine’s weight and pressure system, meaning small machines require 5-10kN, medium 10-20kN, and large 20-30kN.

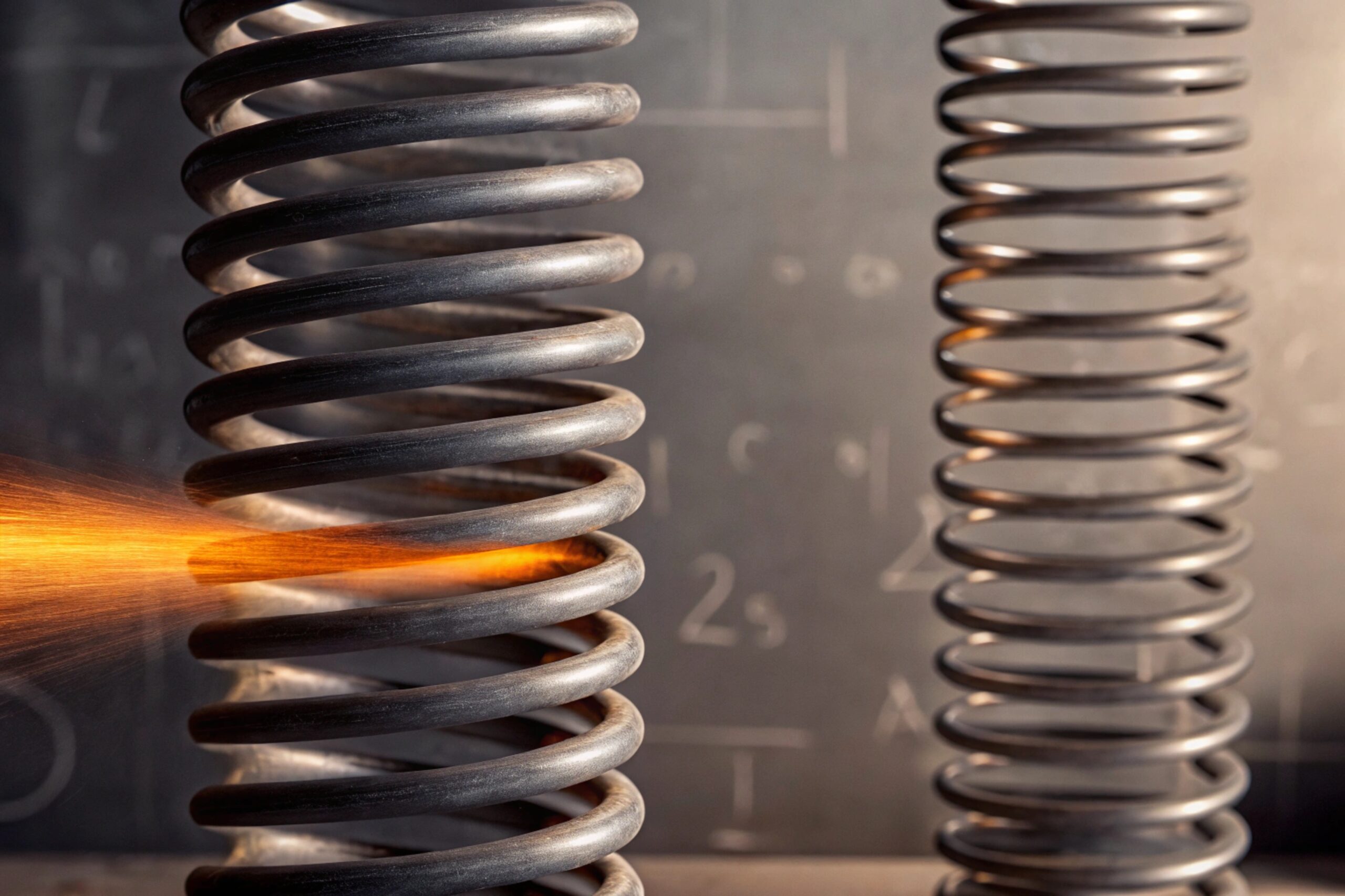

How do I calculate spring rate for my track weight?

The wrong spring rate could lead to broken parts and downtime. Calculating the exact rate is key to a stress-free operation. I need to get this right.

Calculate the spring rate by considering the track weight and machine class. The correct spring rate should correspond closely to machine specifications for optimal recoil and tension management. Miscalculations can lead to component failure and operational issues.

Calculating the spring rate for a track weight 5 entails understanding the tension requirements across the machine’s operating conditions. Begin by examining the spring’s strength, matching it to the machine’s weight and class. Recoil springs should be sized to avoid interference with cylinder bodies and fittings. Think through the free length, accounting for a pre-compression range of roughly 10-20%. The maximum force exerted by the spring should be 80-90% of the cylinder’s rated force—this ensures balanced tension without over-resistance. Evaluate parameters like alloy material choice, opting for 60Si2Mn or 50CrVA spring steels 6 known for high temperature and fatigue resistance. Prioritize rustproof coatings to prevent failure during outdoor operation.

Should I choose nitrogen-charged tensioners for my fleet?

The decision to go with nitrogen-charged tensioners isn’t just a technical choice—it’s all about enhancing fleet reliability and longevity. I don’t want to make a costly mistake here.

Opt for nitrogen-charged tensioners if your fleet demands higher precision load handling and pressure consistency. These tensioners offer enhanced durability and pressure retention compared to standard options, making them suitable for demanding conditions.

When deciding on nitrogen-charged tensioners 7, assess the benefits versus traditional options. Nitrogen-charged models provide superior pressure stability and precision load handling 8, especially for heavy-duty operations. The pressure-retention capability reduces maintenance frequency, enhancing cost-effectiveness. Understand nitrogen tensioners balance against tension cylinders’ hydraulic specifications for fit compatibility. Considering these tensioners’ design, they can withstand harsh operating environments—no sudden pressure drops in rocky or sandy conditions. Prioritize compatibility with existing recoil mechanisms in your fleet, ensuring pressure standards remain consistent.

What maintenance checks prevent tension failures?

Neglecting maintenance can spell disaster for my excavator. Regular checks mean fewer headaches and no surprise failures. I want preventive steps to keep downtime at bay.

Implement regular maintenance checks focusing on components’ integrity and operational balance. Conduct inspections for visible wear, leaks, and ensure proper tension levels are maintained to prevent failures.

Maintenance checks should prioritize a systematic inspection routine covering all aspects of the track adjuster 9. Look closely at hydraulic fitting dimensions for leaks. Conduct a thorough grease system examination to avert potential cylinder replacement. Regularly check the recoil spring’s lifespan by assessing compression strength, key to maintaining tension balance. Inspect the greasing system integrity to identify leakage. Assess spring alignment under full track weight, preventing disproportional wear. Evaluate seal condition to confirm adequate sealing function—weak seals can compromise tension cylinders. Verify the entire system against OEM standards 10 to secure reliability and longevity. Conduct these checks bi-weekly to ensure performance.

Conclusion

Choosing the right components and conducting regular checks ensures my excavator offers reliable performance with minimal downtime.

Footnotes

1. Learn what track tension cylinders do and how they function. ↩︎

2. Understand the role of recoil springs in undercarriage systems. ↩︎

3. An overview of the key components of an excavator’s undercarriage. ↩︎

4. See how cylinder diameter impacts tension and compatibility. ↩︎

5. A guide on spring rate calculation for heavy equipment. ↩︎

6. Compare high-fatigue resistance spring steel alloys. ↩︎

7. Explore the benefits of using nitrogen tensioners in excavators. ↩︎

8. Read how advanced tensioners improve precision load handling. ↩︎

9. Review the function and components of a track adjuster assembly. ↩︎

10. Find out why adhering to OEM standards is crucial for part reliability. ↩︎