When I started examining our incoming quality control process 1 for excavator undercarriage parts, I realized how complex this task could be. Would our standards match our end goal of high performance and durability?

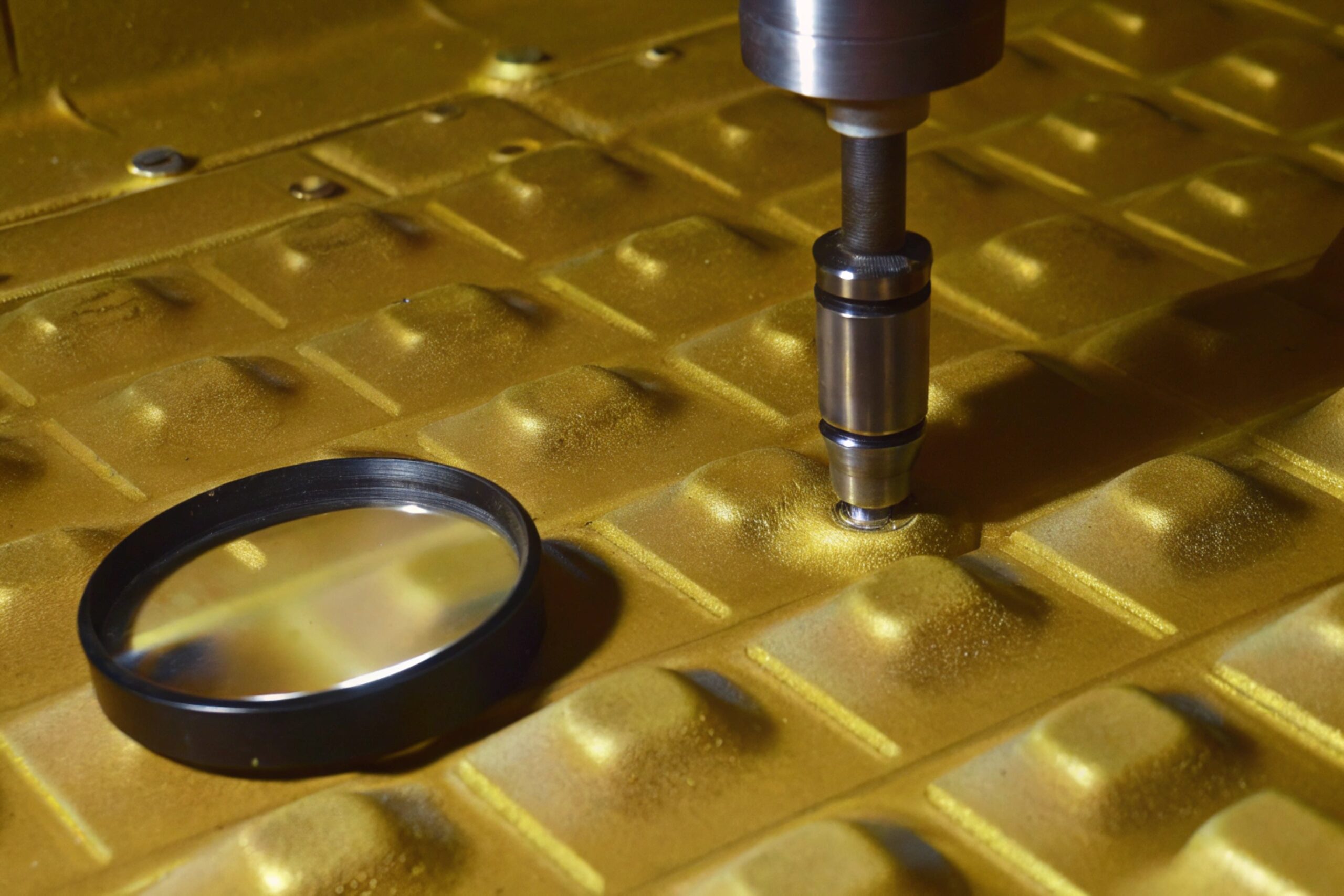

Establishing QC standards for excavator undercarriage parts involves clearly defining dimensional, hardness, appearance, and concentricity specifications. These parameters ensure excavator undercarriage parts 2 meet necessary operational criteria. Working closely with suppliers and leveraging precision measurement tools 3 are crucial for maintaining consistency.

Our goal is to cement customer trust by ensuring every part meets strict quality standards. Let’s dive deeper into the specifics that help achieve this.

Which gauges and tolerances should I specify in my IQC?

When I delved into specifying the right gauges, I was overwhelmed with choices and technical details. Would I be able to pinpoint the most suitable ones?

Ensuring accurate measurement and tolerance specifications is pivotal to quality control. Correct gauges, such as micrometers and calipers for dimensional and hardness assessments, must align with defined tolerances set by OEMs or specific project requirements.

Understanding the need for precise gauges and tolerances is vital. For instance:

Dimensional Checks:

| Specification | Tool | Tolerance |

|---|---|---|

| Pin-to-Pin Distance | Vernier Caliper | ±0.1mm |

| Track Shoe Thickness | Micrometer | ±0.2mm |

The use of certified calibration tools 4 helps ensure measurement accuracy. Dimensional control, crucial for the fitment and assembly of parts, involves using inner diameter micrometers or bore gauges, digital calipers, and specific jigs for elongation assessments.

Hardness Testing:

| Component | Scale | Typical Range |

|---|---|---|

| Track Links | Rockwell | HRC 45-55 |

| Sprockets | Brinell | 500-700 HB |

Hardness testing using precise devices like Rockwell scales 5 ensures parts can withstand operational stresses without rapid wear or failure. Moreover, uniform hardness distribution without soft spots is critical to maintaining part integrity.

By adhering to these detailed standards, manufacturing consistency is elevated, thereby enhancing part longevity and performance. Coordination with suppliers ensures these specifications are met during production.

How many samples do I inspect per lot for my parts?

I was initially unsure about the sample size needed for effective quality control. How could I balance thorough inspection without overburdening the process?

Determining appropriate sample sizes is a balancing act between thoroughness and efficiency. Inspecting sufficient samples ensures part quality is consistently maintained without unnecessary resource strain.

Consistent sampling ensures quality and mitigates risks. Here’s a typical inspection plan approach:

Sample Inspection Guide:

| Lot Size | Sample Size (ISO 2859-1) | Inspection Level |

|---|---|---|

| 1 – 100 | 8 | General II |

| 101 – 500 | 12 | General II |

| 501 – 1000 | 20 | General II |

According to ISO 2859-1 6 standards, sampling plans are established based on lot sizes. More massive lots require larger samples for accurate assessment. Performing multiple checks on critical dimensions and hardness on each sample reduces variability and ensures consistency.

Furthermore, balanced sampling underpins the ability to consistently detect defects, directing focus towards corrective measures, ultimately strengthening the quality control framework.

At first, I wondered whether suppliers would willingly open up about their control plans. Was it reasonable to expect this level of transparency?

Collaboration with suppliers on control plans and Production Part Approval Processes 7 (PPAPs) facilitates alignment with established quality standards, leading to fewer discrepancies in the long run.

Working hand-in-hand with suppliers fosters transparency and continuous improvement. Suppliers sharing detailed control plans, including process flows, control charts 8, and PPAP documentation, builds trust and communication.

Supplier Collaboration Best Practices:

- Control Plan Review: Regularly review supplier control plans to ensure alignment with your IQC standards.

- Documentation Sharing: Encourage suppliers to share PPAP files including FMEA 9 and control charts.

- Feedback Mechanism: Establish feedback loops to quickly address quality concerns and drive continuous improvement.

Supplier cooperation in these areas ensures parts meet required quality benchmarks, blending supplier processes with buyer expectations. The outcome is minimal disputes over part quality, boosting operational efficiency.

What acceptance criteria reduce disputes on defects?

Many times, I’ve faced challenges clarifying acceptance criteria. How could I reduce disputes with suppliers over quality issues?

Clear acceptance criteria serve as a mutual understanding between suppliers and manufacturers on what constitutes a defect, eliminating ambiguities that often lead to disputes.

Defining clear criteria mitigates misunderstandings and supports seamless operations. A practical approach involves standardizing defect thresholds and providing visual references:

Acceptance Criteria Framework:

| Defect Type | Acceptance Standard | Inspection Method |

|---|---|---|

| Surface Cracks | None | Visual and Magnetic Particle Inspection |

| Porosity | Max. Diameter 1mm | Visual Inspection |

Utilizing standardized defect criteria allows for explicit expectations, reducing subjectivity in inspections. Establishing these helps streamline supplier relationships and enhances trust through consistent expectations.

For critical detection, using methods like Magnetic Particle Inspection 10 ensures that invisible surface cracks are identified before shipment.

By reducing ambiguity, this framework promotes better communication and mutual understanding with suppliers, preventing recurring quality issues.

Conclusion

By understanding these intricate details in quality control, incoming standards for excavator parts can be methodically established, securing durability and performance while maintaining smooth supplier relations.

Footnotes

1. Detailed overview of incoming quality control vs quality assurance. ↩︎

2. Technical explanation of excavator undercarriage components and functions. ↩︎

3. Guide to selecting measurement tools for industrial accuracy. ↩︎

4. Importance of NIST-traceable calibration for manufacturing tools. ↩︎

5. Standard test methods for Rockwell hardness of metallic materials. ↩︎

6. ISO standard explaining sampling procedures for inspection by attributes. ↩︎

7. AIAG guide on the Production Part Approval Process (PPAP). ↩︎

8. How to use control charts to monitor process stability. ↩︎

9. Understanding Failure Mode and Effects Analysis for risk reduction. ↩︎

10. Educational resource on Magnetic Particle Inspection (MPI) techniques. ↩︎