Ensuring precise measurements and fit is crucial for undercarriage part longevity. In my operations, careful control of bush dimensions is imperative, as inaccuracies could lead to failures.

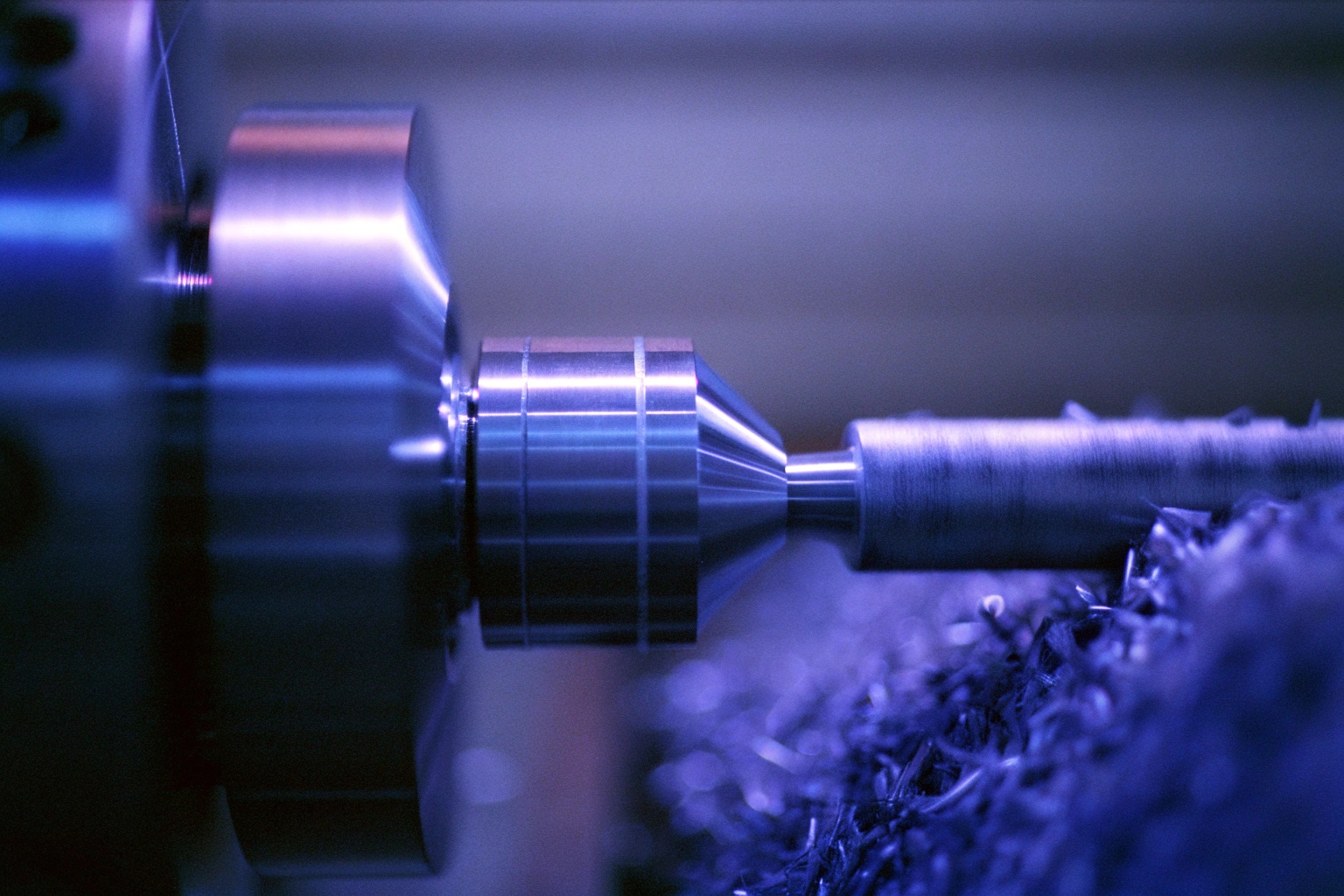

We employ precision CNC machining 1 to achieve accurate control over the bush outer and inner dimensions. Regular tolerance checks maintain desired interference fit specifications. To ensure consistent product quality, bush OD/ID measurements are performed using micrometers and calipers, backed by automated inspection systems 2.

Will you show me your press-fit curves and fixture control plan for my undercarriage parts?

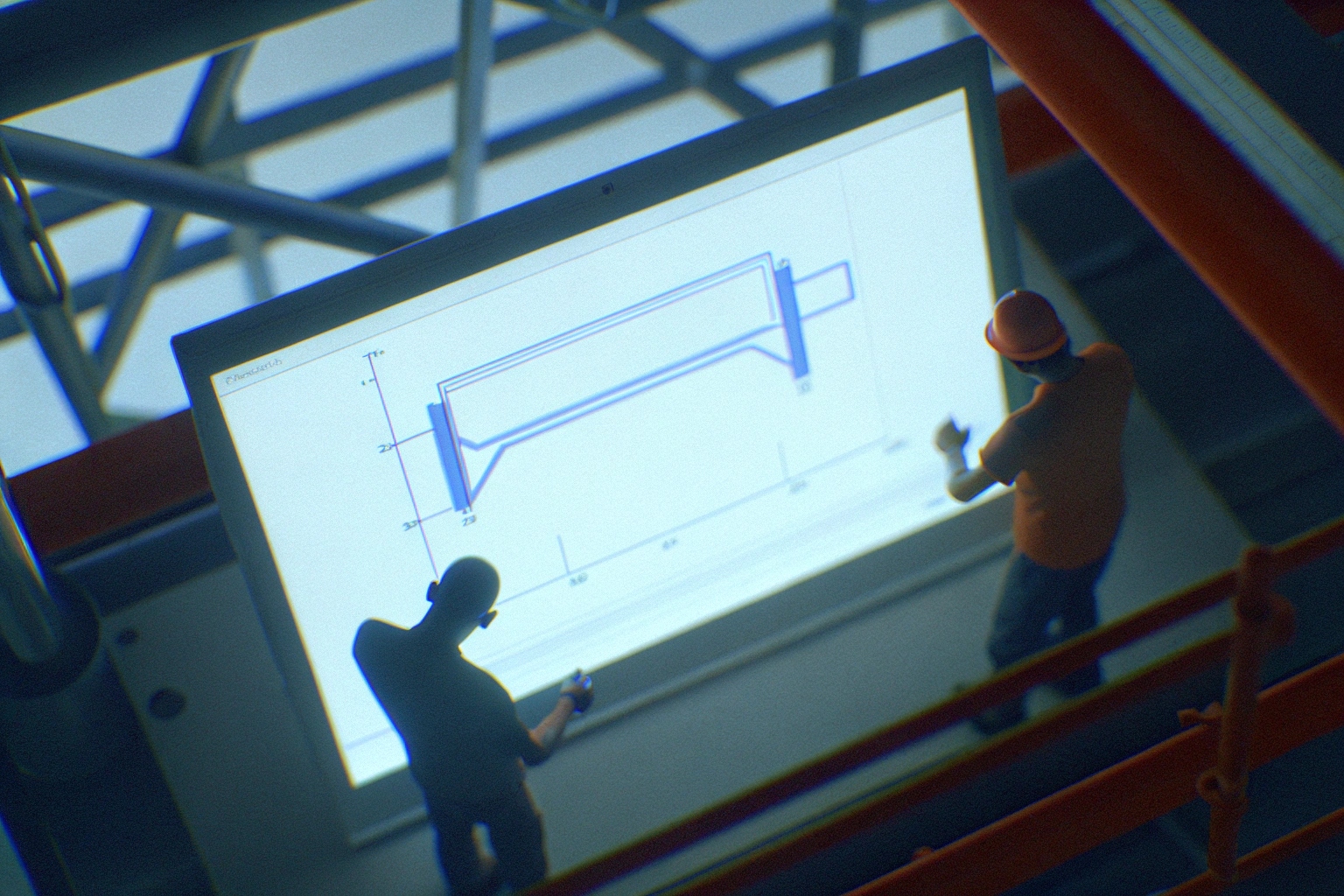

Understanding the press-fit curve 3 and fixture control is key to maintaining quality. In my work, I ensure that these elements are closely monitored and optimized to meet specifications.

Our press-fit curves are meticulously plotted to ensure consistent interference fits. We use detailed fixture control plans to guarantee reliable measurements and assembly. These procedures are regularly reviewed and updated to enhance product quality.

We use precise techniques to maintain fixture integrity and consistently produce high-quality parts. By implementing regular audits and corrective actions, deviations in fit specifications are efficiently addressed. Statistical sampling plans 4 help us determine inspection frequencies that ensure ongoing reliability.

Can you provide SPC data for ID/OD to prove process capability for my undercarriage parts?

Statistical process control (SPC) data 5 provides transparency into manufacturing processes. For my operations, demonstrating capability and consistency through SPC data is crucial for building trust.

SPC data is collected for bush ID/OD measurements to show process capability and identify areas for improvement. This data aids in making informed decisions about future production and quality control methods.

By utilizing SPC, we ensure high availability for process insights, allowing proactive adjustments to enhance outcomes. Our continuous improvement programs leverage inspection data feedback to refine control measures, supporting long-term reliability.

Do you offer different interference ranges for SALT vs dry chains I order for my undercarriage parts?

For different environments, varying interference fits are required to promote longevity. I ensure that flexibility in service offerings matches diverse operating conditions.

We provide distinct interference ranges for SALT and dry chains 6. This prevents bush rotation and supports optimal performance under specific conditions. Our intervention aligns these ranges with international standards 7, ensuring effectiveness.

To match the unique requirements of SALT or dry chains, we adjust bush dimensions accordingly. This personalized approach solidifies quality, promoting durability and maintaining operational efficiency across different scenarios.

How do you prevent bush ovality affecting service life for my undercarriage parts?

Bush ovality 8 can drastically reduce a part’s service life. To counteract this, I employ various strategies that ensure dimensional stability for critical components.

Reducing bush ovality begins with careful machining, using techniques to preserve roundness. Regular inspections help detect deviations early, allowing swift intervention.

Controlling bush dimensions involves extensive use of precision tools for accurate and consistent results. Our commitment to quality ensures that each part is capable of delivering peak performance throughout its lifespan. By monitoring for signs of ovality, adjustments are made in real-time to guarantee reliability.

Conclusion

Accurate control over bush dimensions ensures reliable undercarriage parts, supporting optimal performance in varied conditions. Precision and continuous monitoring are key to maintaining quality.

Footnotes

1. CNC machining enhances dimensional control for precision parts. ↩︎

2. Automated inspection systems improve measurement accuracy and reliability. ↩︎

3. Understanding press-fit curves ensures proper interference fit and assembly quality. ↩︎

4. Statistical sampling determines efficient inspection intervals. ↩︎

5. SPC provides insights for process consistency and capability. ↩︎

6. Differentiated interference fits cater to specific environmental conditions. ↩︎

7. Adherence to international standards ensures compliance and effectiveness. ↩︎

8. Preventing ovality enhances service life by maintaining precise dimensions. ↩︎

9. Statistical techniques support continuous quality improvements. ↩︎

10. Fixture control plans help maintain assembly accuracy and quality. ↩︎