In the construction industry, every detail counts, especially when it comes to the parts that power your heavy machinery. As someone deeply invested in ensuring the durability and efficiency of machine parts, I understand the challenges of maintaining high standards in undercarriage components.

To guarantee sprocket ring and segment tooth profile standards 1, tip hardness, and the depth of hardening, precise manufacturing processes and rigorous quality checks are vital. Using CNC machining, these parts achieve the desired precision and design specifications. Testing methods like Rockwell or Vickers scales 2 assess tip hardness, while microhardness testing ensures the hardened layer depth. These processes ensure uniformity and compliance with stringent requirements.

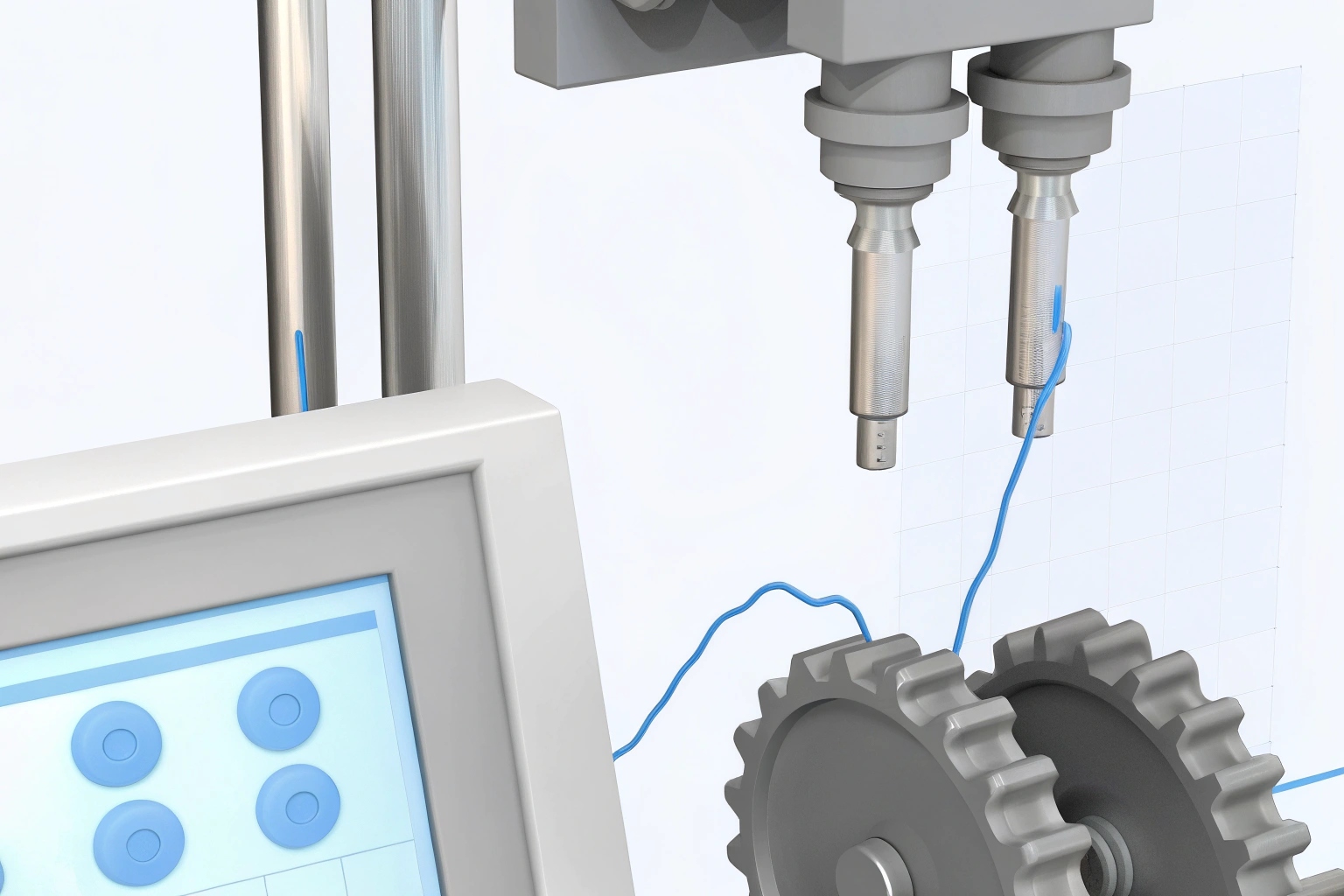

Ensuring top-tier quality in our undercarriage parts for excavators & bulldozer involves a systematic approach. Our quality control processes include detailed dimensional checks and profile verification using cutting-edge metrology equipment 3. This is crucial for maintaining international standards such as ISO and ASTM 4. Furthermore, consistent monitoring and audits maintain product reliability and ensure that every product leaving our facility meets the required quality benchmarks.

Will you provide tooth profile gauges and calibration records for my audit for my undercarriage parts for excavators & bulldozer?

Providing access to quality and calibration records 5 is essential, especially when audits are a routine part of your business. It offers an assurance of the quality you can expect when working with us.

All tooth profile gauges come with detailed calibration records. These records document the adherence to specific standards and ensure compliance with high-quality requirements. Our quality control includes rigorous checks that cover every aspect, including dimensional, profile, and finish. Additionally, we maintain these records meticulously for every audit.

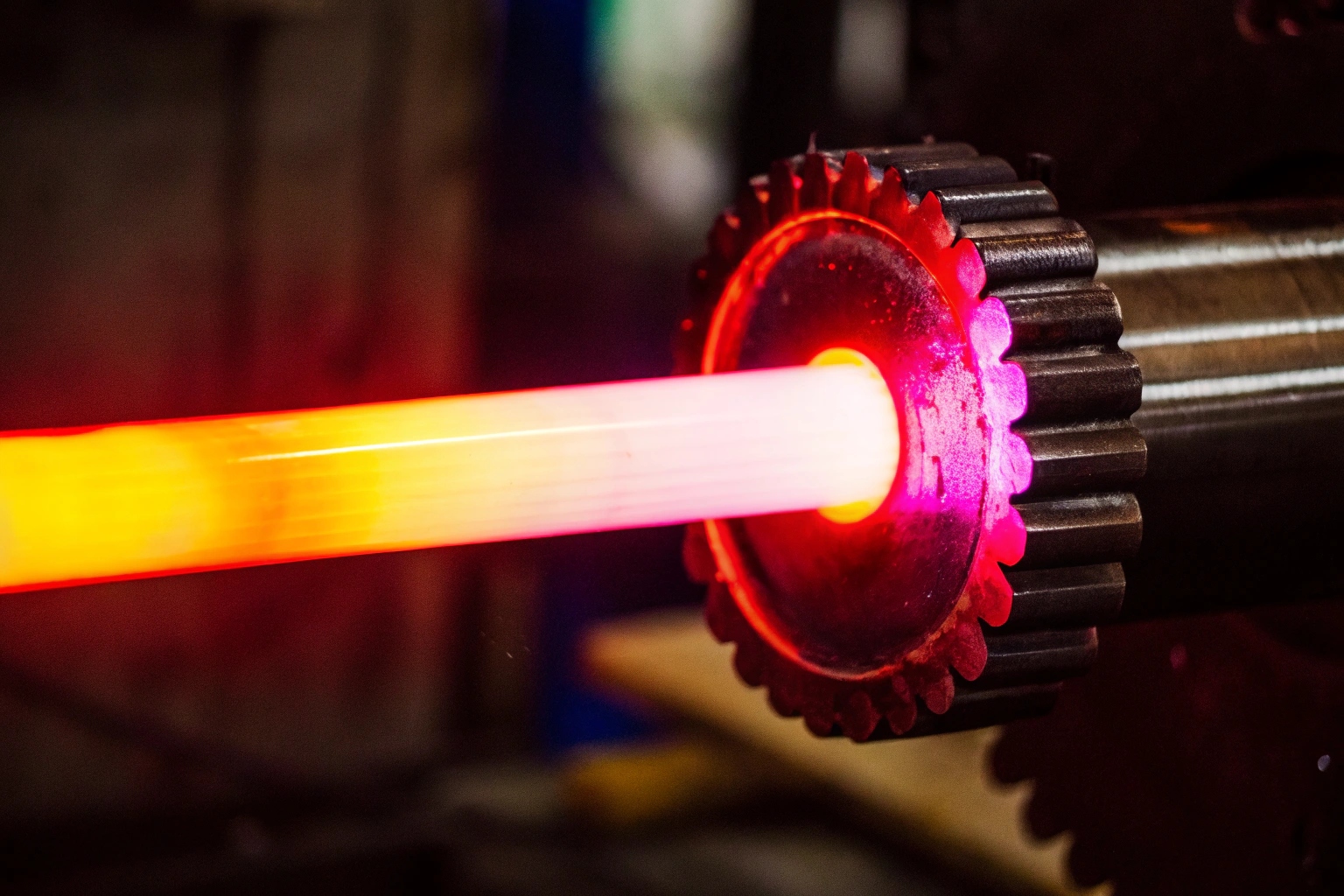

Our manufacturing process involves precision machining techniques such as flame machining and hobbing 6 to ensure accurate tooth profiles. These profiles must conform to OEM and international standards, ensuring correct chain engagement. Throughout production, process controls monitor parameters to sustain accuracy and prevent deviations.

| Inspection Type | Method Used | Frequency |

|---|---|---|

| Dimensional Checks | Advanced metrology equipment | Every batch |

| Profile Verification | CNC inspections | Every batch |

| Calibration Records | Documented and available | On request |

Our commitment to quality is reflected in our transparency during audits. These checks not only confirm compliance but also facilitate improvements.

Can you meet OEM tip hardness and EHD for my high-impact jobs for my undercarriage parts for excavators & bulldozer?

Meeting the highest standards in tip hardness and effective hardened depth (EHD) 7 is key. It reflects our commitment to delivering parts capable of handling high-impact tasks.

We meet OEM tip hardness and effective hardened depth (EHD) through robust heat-treatment processes, primarily induction or flame hardening. This ensures localized surface hardening while maintaining a ductile core for shock absorption.

In our production, several key practices are followed:

Heat Treatment and Hardening

- Induction Hardening: Utilizes controlled heating and rapid cooling for surface hardness.

- Flame Hardening: Focuses on high-wear areas while protecting the core.

Quality Testing

- Hardness Testing (Rockwell HRC) 8: Ensures adherence to specific standards, often 50 HRC or higher.

- Case Depth Measurement: Employing microhardness methods (e.g., Vickers, Knoop) 9.

Quality Assurance

- Real-Time Monitoring: Tracks parameters such as energy and quenching for repeatability.

- Records Maintenance: Full documentation including material certificates and hardening data.

These practices ensure that our sprockets are prepared for the most demanding applications.

Do you run wear testing to compare your sprockets with my OEM ones for my undercarriage parts for excavators & bulldozer?

Comparative wear testing 10 is critical in assessing how our products hold up against OEM components. This information not only assures but also improves our offerings.

Yes, we conduct extensive wear testing to compare our sprockets with OEM specifications. This testing ensures our products meet, or even exceed, the durability and performance of traditional OEM components.

Testing Process

- Simulated Loading Conditions: Replicates real-world stressors.

- Controlled Environments: Monitoring in different terrains and conditions.

- Data Collection and Analysis: Frequent checks during testing aid in evaluating performance.

| Test Aspect | Evaluation Criteria | Tools Used |

|---|---|---|

| Wear Patterns | Surface degradation | Optical Microscopes |

| Resistance Tests | Endurance over time | Hardness Testers |

| Durability Checks | Lifecycle Analysis | Load Testing Machines |

This comprehensive approach is essential for ensuring our sprockets provide best-in-class performance and value.

Can I order segments with special tooth geometry for my terrain for my undercarriage parts for excavators & bulldozer?

The possibility of customizing parts like sprockets can provide a competitive edge. These modifications can significantly impact performance in varied terrains.

Yes, ordering segments with special tooth geometry tailored to specific terrains is possible. Customization is a key attribute that many of our clients find valuable.

Customization Process

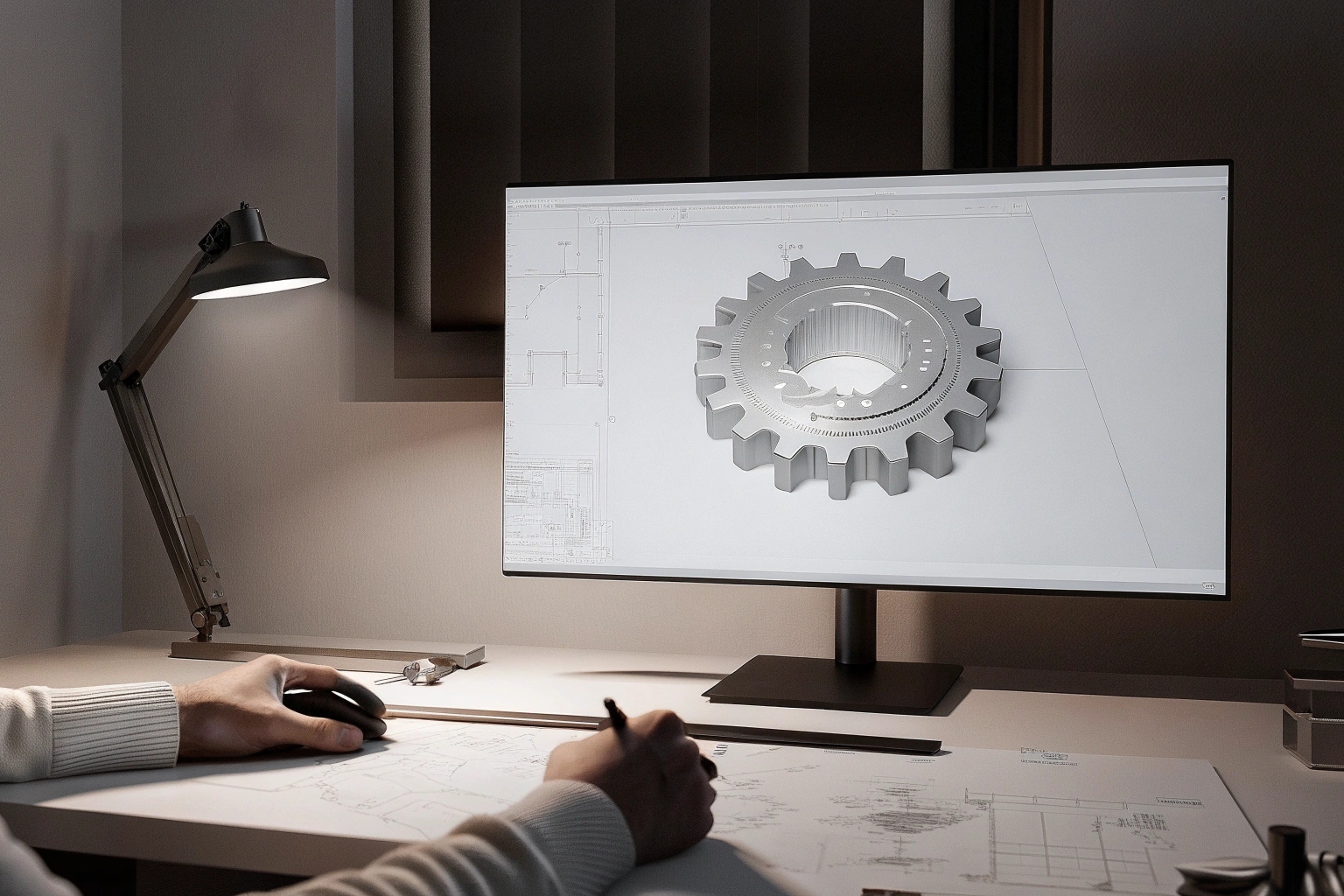

We begin by assessing the client’s needs and the specific terrain conditions. From there, our engineers collaborate with clients to design tooth geometries that optimize performance.

Design and Manufacturing

- 3D Modeling: Visualizes custom tooth designs.

- Material Selection: Chooses base materials suitable for custom modifications.

- Prototype Development: Constructs initial prototypes for testing.

Testing and Verification

- Field Testing: Evaluates custom components in practical conditions.

- Iterative Refinement: Further adjustments based on field data and feedback.

| Customization Step | Tools and Techniques | Benefits |

|---|---|---|

| Design Consultation | CAD Software | Optimized Efficiency |

| Prototype Testing | Real-world Application | Performance Assurance |

| Production Roll-out | Advanced Machining | Timely Delivery |

This capability not only enhances operational effectiveness but also maximizes equipment lifespan in challenging conditions.

Conclusion

Consistent quality assurance and the ability to customize ensure that our undercarriage parts for excavators & bulldozer meet the precise needs of our clients.

Footnotes

1. Overview of sprocket profile standards for quality assurance. ↩︎

2. Explanation of hardness scales for precision testing. ↩︎

3. Importance of precision in measurement for part conformity. ↩︎

4. Overview of international manufacturing standards like ISO and ASTM. ↩︎

5. Role of calibration in maintaining product quality. ↩︎

6. Description of machining techniques for tooth profile accuracy. ↩︎

7. Importance of meeting OEM standards for durability. ↩︎

8. Ensuring part durability through hardness testing. ↩︎

9. Methods for measuring case depth for surface hardening. ↩︎

10. Detailed look at the wear testing process for quality assurance. ↩︎