Consistency is crucial for manufacturing success, and we’ve faced challenges in making sure our samples match mass production. By keeping a "Golden Sample" 1, we ensure every part produced meets your approved standard.

We keep a "Golden Sample," formally known as the Master Sample, as part of the PPAP process 2. This sample serves as the benchmark for consistency in manufacturing your undercarriage parts for excavators & bulldozer. Each part produced aligns with this standard through the implementation of rigorous control plans and quality checks, ensuring adherence to the approved specifications.

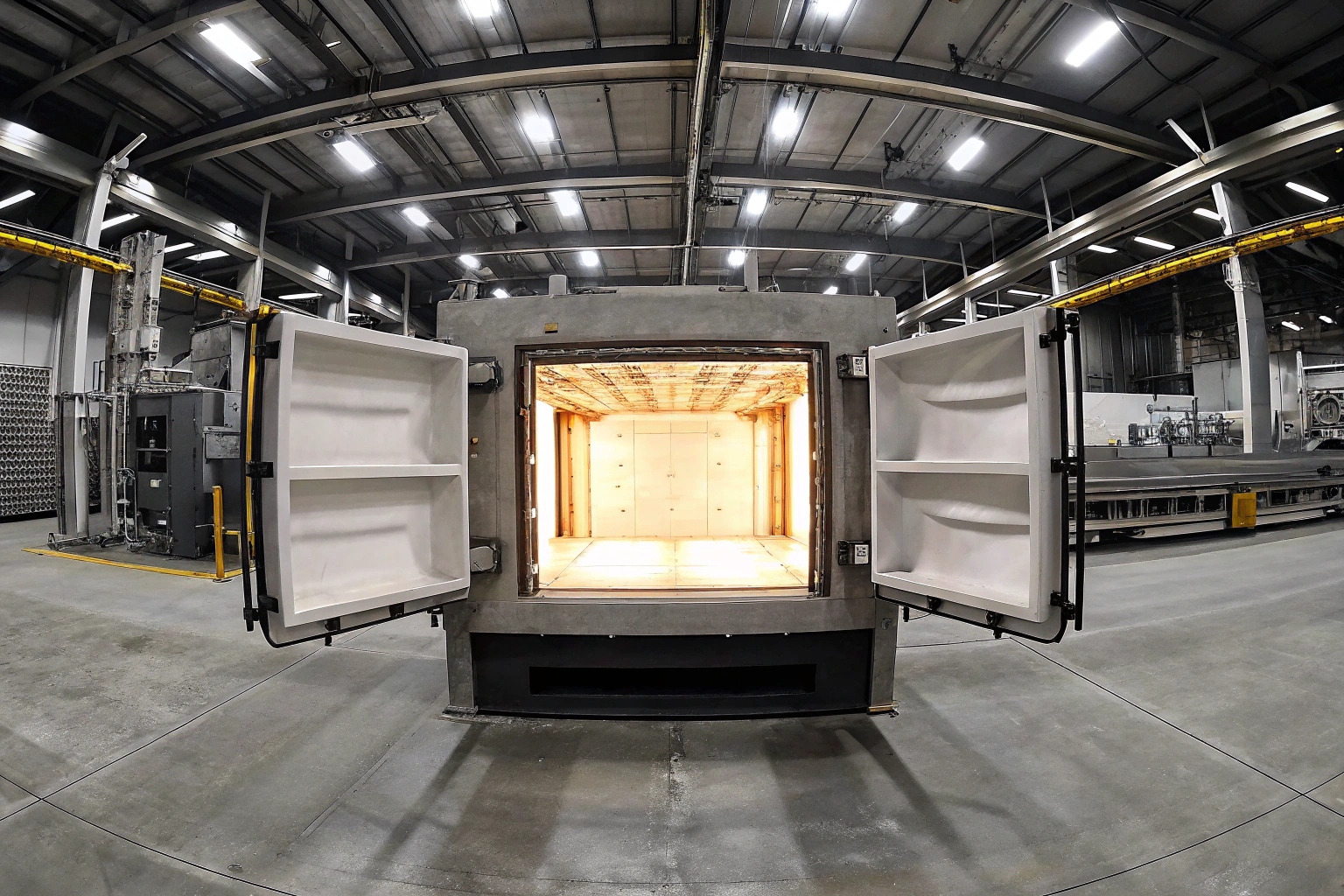

Adopting PPAP frameworks 3, we retain golden samples in our quality lab, providing a tangible benchmark for manufacturing. Our detailed control plans guide production, ensuring each part aligns with the master sample in materials and specifications.

Can I sign off a master sample with sealed data for my PPAP for my undercarriage parts for excavators & bulldozer?

Signing off on the master sample can feel daunting but is essential. I’ve found that sealed data 4 ensures quality control and aligns production with your expectations.

Yes, you can sign off a master sample with sealed data for your PPAP. The master sample acts as a reference to ensure each production run adheres to the approved specifications and quality standards, offering you confidence in consistency throughout the lifecycle of your undercarriage parts for excavators & bulldozer.

Creating a standardized master sample provides clarity and benchmarks for manufacturing processes. This allows firms to retain consistency across multiple batches, ensuring all parts adhere to the approved specifications.

Will you lock critical processes and tools after my approval for my undercarriage parts for excavators & bulldozer?

Maintaining stability in manufacturing can be challenging. I’ve learned that locking critical processes 5 assures alignment with your standards, preventing deviations in production.

Yes, we lock critical processes and tools after your approval. This ensures that nothing changes without consent, preserving the consistency between the master sample and mass production runs, safeguarding product integrity over time.

Securing critical processes helps in preserving quality across production cycles. Audits and inspections verify that approved methods remain in place, ensuring stability and consistency in manufacturing.

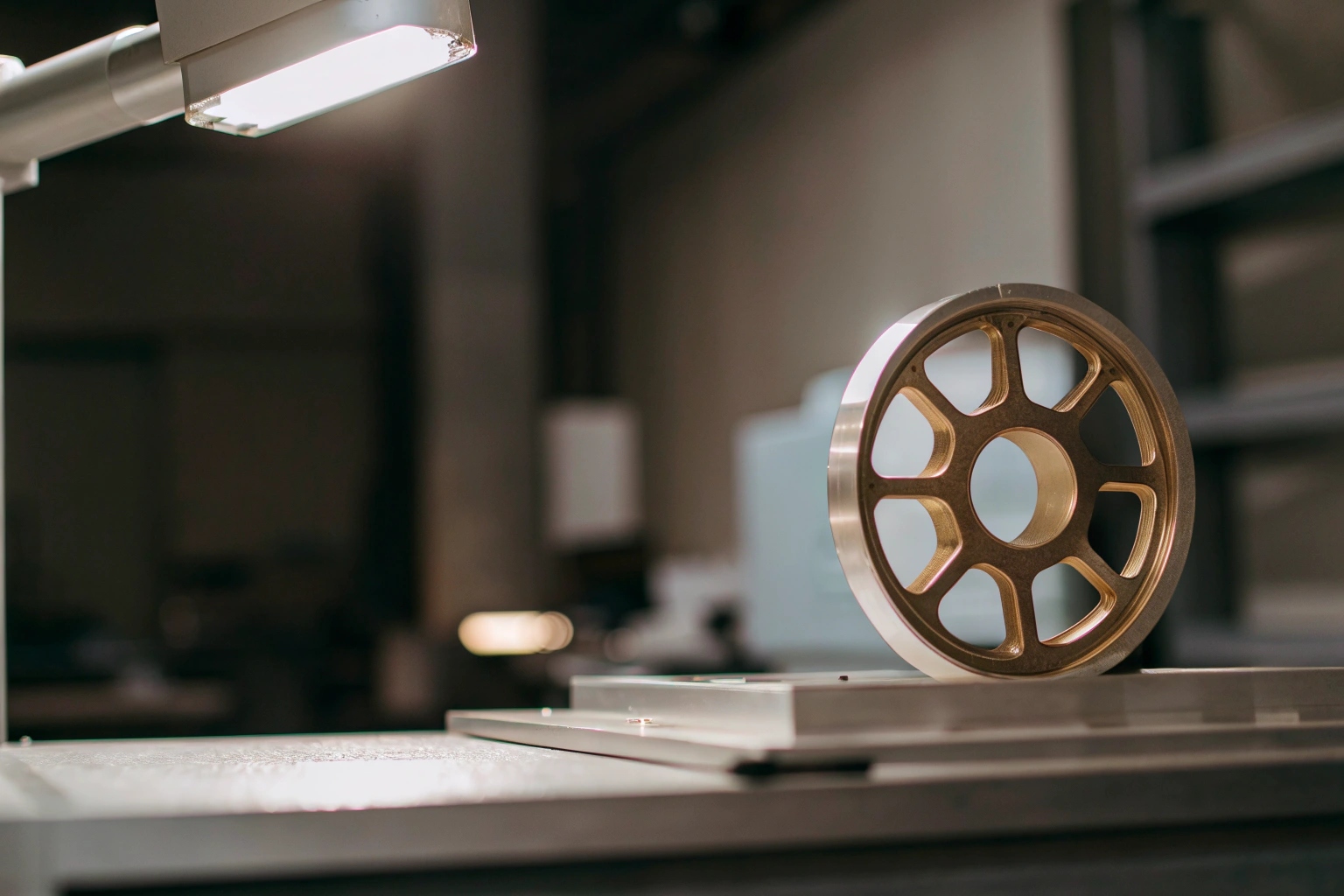

Do you use first-article inspection to match my golden sample for my undercarriage parts for excavators & bulldozer?

Aligning first-article inspections 6 with the golden sample can be intricate. From experience, I’ve learned that prioritizing this ensures the highest product quality for your parts.

Yes, first-article inspections are performed to match the golden sample. By applying statistical process controls 7 and using calibrated measurement tools, zero deviations from approved benchmarks are enforced, maintaining quality in each production batch.

First-article inspections act as a critical step in validating initial production runs against recognized standards. Paired with quality audits, this method guarantees that every piece measures up to the golden sample.

Can I audit tool wear and maintenance records to protect my quality for my undercarriage parts for excavators & bulldozer?

Preservation of tool wear data 8 is vital for quality control. Reviewing maintenance records 9 shows me how they protect part integrity and ensure productivity benchmarks.

Yes, you can audit tool wear and maintenance records. By open access to these records, you verify that all machinery and tools are in prime condition, which helps in ensuring consistent quality for your undercarriage parts for excavators & bulldozer.

Auditing tool records offers insights into proper maintenance practices, ensuring that machinery operates efficiently. This guarantees the stability and consistency of production cycles, preserving product quality standards.

Conclusion

Consistency in manufacturing is achieved by combining rigorous control plans, golden sample benchmarks, and regular audits to meet quality standards consistently.

Footnotes

1. Golden Sample methodology ensures product consistency. ↩︎

2. PPAP process aids quality assurance in manufacturing. ↩︎

3. Understanding PPAP ensures better production quality control. ↩︎

4. Sealed data enhances master sample reliability. ↩︎

5. Learn why locking production processes preserves product quality. ↩︎

6. First-article inspections maintain production quality. ↩︎

7. Statistical process control keeps manufacturing processes stable. ↩︎

8. Tool wear data can indicate manufacturing quality. ↩︎

9. Maintenance records ensure machinery efficiency. ↩︎

10. Visit Dingtai for undercarriage parts for excavators & bulldozer solutions. ↩︎