Ever wonder what keeps an excavator moving seamlessly 1 on challenging terrains? Understanding the intricate components of excavator undercarriages can help ensure smooth and efficient operation. Familiarizing yourself with these parts can minimize unexpected breakdowns.

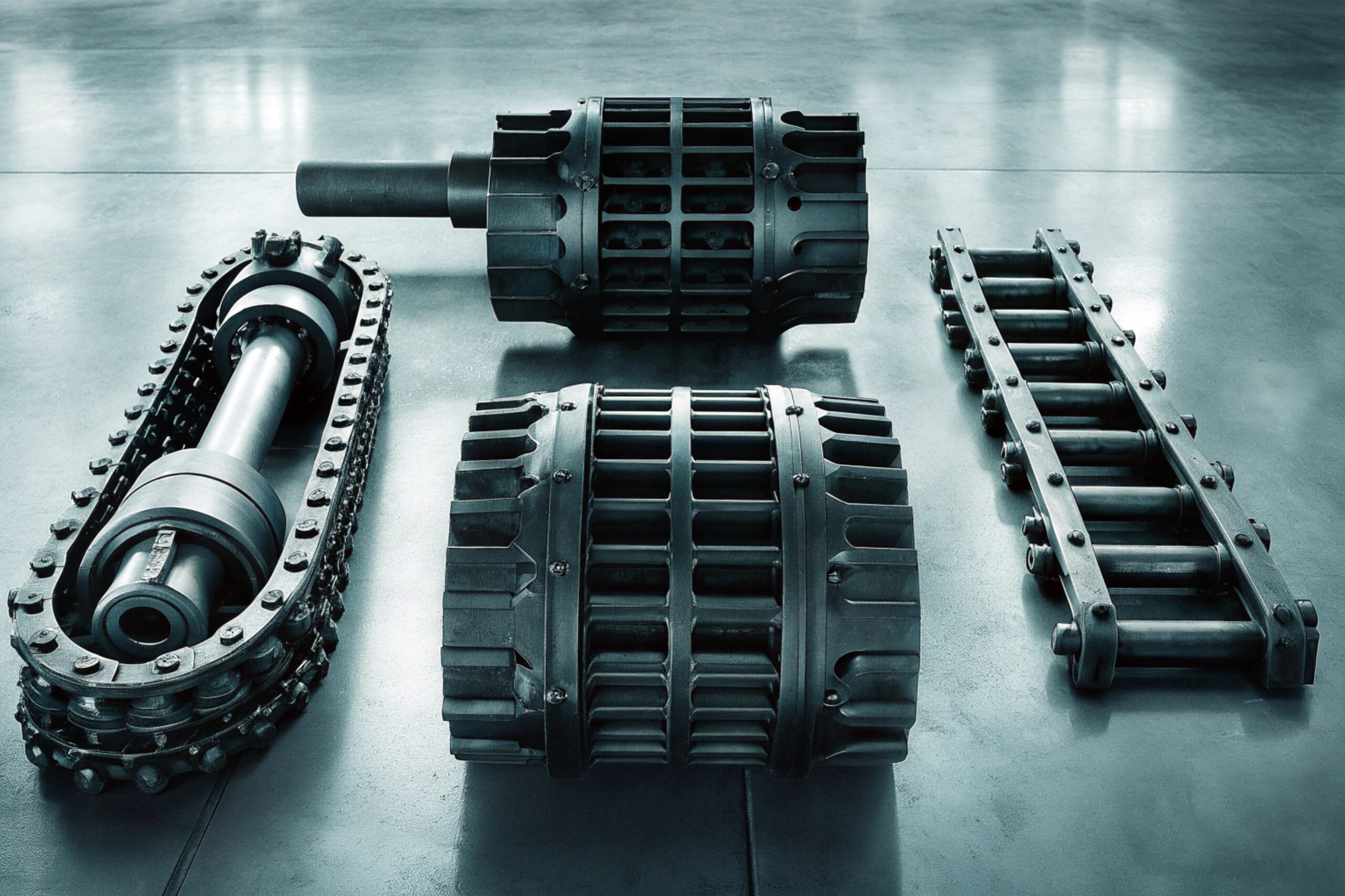

Excavator undercarriage parts include tracks, track rollers 2, idlers, sprockets, and track chains. These core components support the machine’s weight, provide mobility, and help in transmitting the engine’s power to the ground. This system ensures the excavator can adapt to complex working conditions while absorbing operational shocks and vibrations.

Understanding the function of these parts is crucial. Each component plays a specialized role. Track chains link the track sections together, while sprockets 3 convert rotational motion into linear movement. Proper maintenance of these parts not only prolongs their lifespan but also optimizes the machine’s performance. Below is a detailed table illustrating the critical components of an excavator undercarriage.

| Component | Description | Function |

|---|---|---|

| Tracks 4 | Metal or rubber strips encircling the undercarriage | Ensure ground traction and mobility |

| Track Rollers | Support the excavator’s weight and enable movement | Enable smooth rolling and motion |

| Sprockets | Toothed wheels driving the track chain | Convert rotational movement into linear motion |

| Idlers | Provide guidance and maintain track tension | Prevent derailment and support stability |

Which undercarriage parts wear fastest on my excavators?

Undercarriage maintenance can often feel like a guessing game. Identifying the parts that wear faster 5 can save time and money by preventing sudden failures. The right knowledge cuts down unnecessary downtime.

The faster-wearing parts of an excavator undercarriage typically include track rollers 6, idlers, and sprockets. Personalized maintenance schedules help extend the lifespan of these components. Adapting to environmental factors and operational demands can be key.

The rate of wear on undercarriage parts depends on a variety of factors. Conditions like abrasive rocks, sandy soil, and operating loads can greatly affect how quickly parts wear out. Understanding these factors helps in scheduling timely maintenance 7 and replacements, ensuring maximum uptime and minimizing operating costs. Adopting a proactive approach in monitoring wear levels guarantees the excavator’s reliability over time.

How do I identify compatible undercarriage parts for my fleet?

Navigating the complex market of undercarriage parts can be daunting. Ensuring compatibility is crucial for maintaining performance and avoiding disruptions. Knowing what criteria to look for helps avoid potential mismatches.

To identify compatible undercarriage parts 8, consider factors such as the make and model of your equipment, existing wear patterns, and operational demands. Consulting detailed equipment manuals or experts can offer invaluable guidance.

Choosing the right parts ensures the efficient and continued operation of your fleet. OEM specifications 9, material strength, and component compatibility play key roles. Maintaining clear records of serial numbers and part types significantly aids in accurately identifying replacements. Develop a routine for regularly matching and inspecting parts to uncover any discrepancies early, ensuring performance consistency across your machinery fleet.

What maintenance schedule should I follow for my undercarriage parts?

Staying ahead with maintenance can seem overwhelming. With the right schedule, you’ll keep your fleet running smoothly, minimizing downtime. A personalized schedule is essential for long-term reliability.

A standard maintenance schedule 10 involves routine checks and service for components like track rollers, idlers, and sprockets every 250 to 500 hours of machine operation. Regular lubrication and tension adjustments are crucial.

Regular inspections help identify any signs of excessive wear or malfunction. Factors such as operating conditions and workload impact the frequency of required services. By keeping a detailed log of maintenance activities, operators can predict and plan for part replacements and necessary repairs, reducing unexpected costs and ensuring the longevity of the machinery.

| Maintenance Task | Frequency | Key Activities |

|---|---|---|

| Visual Inspection | Every 250 hours | Check for cracks, excessive wear, and misalignments |

| Lubrication | Every 250 hours | Grease fittings and adjust track tension |

| Comprehensive Check-up | Every 500 hours | Inspect rollers, idlers, sprockets, and track chains |

Where can I buy OEM-grade excavator undercarriage parts?

Finding trustworthy suppliers can be challenging. OEM parts ensure consistent quality and compatibility. Knowing where to find them streamlines procurement, promoting peace of mind.

OEM-grade excavator undercarriage parts can be purchased from authorized dealers, reputable online platforms, and specialized equipment suppliers. These sources offer genuine parts, upholding performance and reliability.

Engaging directly with manufacturers or their authorized distributors often secures the best quality parts. Regularly participating in industry trade shows provides access to a broader network of suppliers. Building long-term relationships with these trusted suppliers guarantees access to authentic parts, beneficial pricing, and excellent support. This ongoing relationship can be a key factor in the successful management of your equipment fleet.

| Trusted Source | Platform Type | Offering |

|---|---|---|

| Authorized Dealers | Physical/Online | Direct access to OEM products |

| Reputable Online Markets | Online Platforms | Wide range of brands and components |

| Trade Shows | Physical Events | Networking opportunity with global suppliers and experts |

Conclusion

Understanding excavator undercarriage parts is vital for efficient maintenance and operation, ensuring prolonged machinery life and optimal performance.

Footnotes

1. Explore how excavators maintain motion on all terrains. ↩︎

2. Importance of track rollers in equipment movement. ↩︎

3. How sprockets facilitate excavator mobility. ↩︎

4. Overview of different track materials and uses. ↩︎

5. Tips to reduce wear on excavator undercarriage parts. ↩︎

6. Guide to prolonging the life of track rollers. ↩︎

7. Essential maintenance practices for heavy equipment. ↩︎

8. How to ensure part compatibility with machinery. ↩︎

9. Role of OEM specifications in equipment performance. ↩︎

10. Creating effective maintenance schedules for fleets. ↩︎