Production lead times can be nerve-wracking, especially when dealing with complex machinery parts. I often find myself grappling with uncertainties and trying to plan effectively to meet my business demands.

Typically, regular models take 45 to 60 days, while custom ones may require 75 to 90 days if tooling is completed. Moreover, new custom designs can take up to 22 to 29 weeks due to extensive prototyping requirements. Therefore, foresight is crucial.

Understanding that efficient logistics 1 and advanced planning significantly influence timelines, I often ensure to initiate orders well ahead of peak demand periods 2. This strategy helps mitigate risks inherent in production schedules.

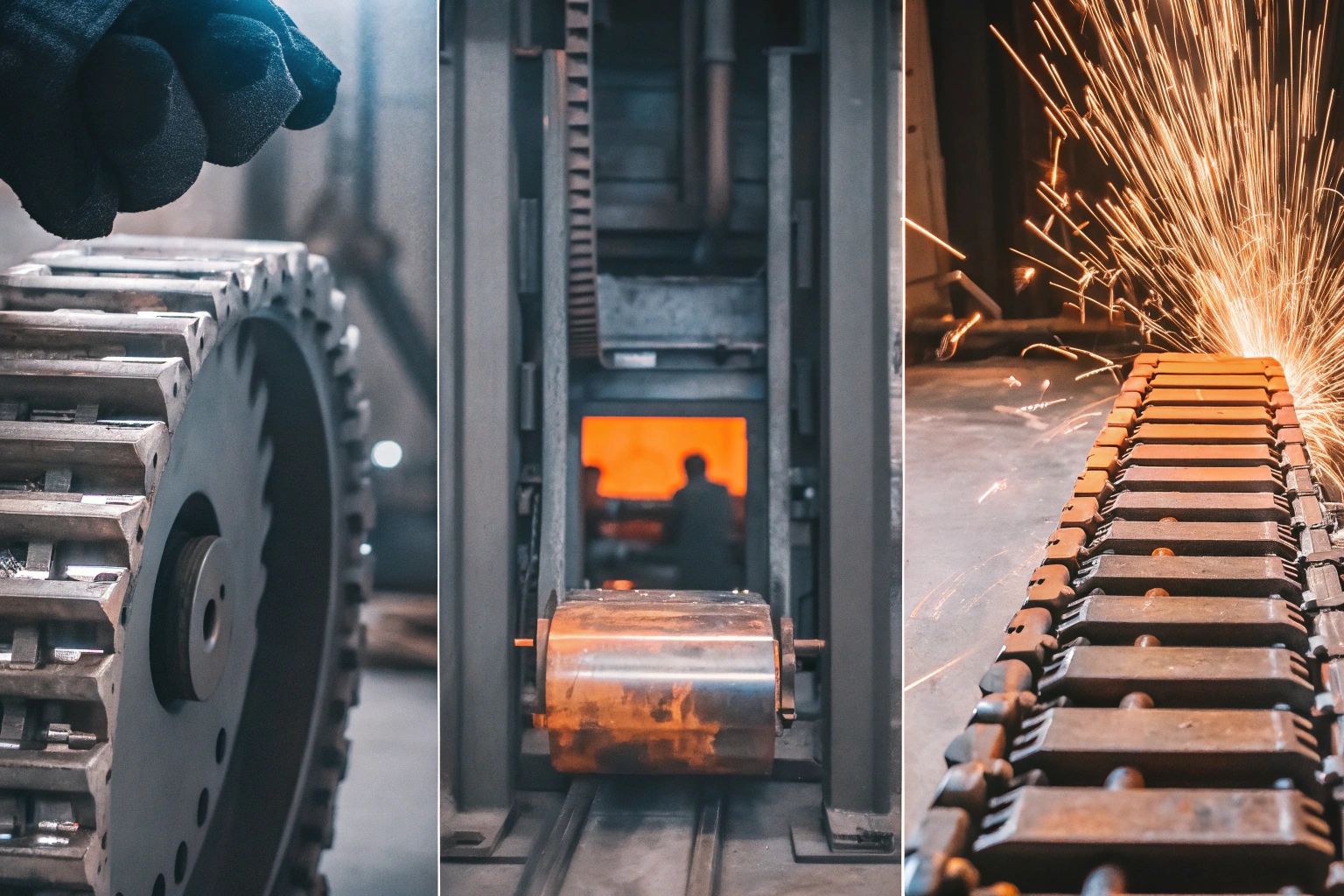

Machining, heat treatment, and assembly are integral parts of manufacturing processes. I’ve often faced challenges amidst uncertainties, juggling demand versus lead times. The importance of these steps can’t be underestimated.

Machining usually consumes around 15-20 days, heat treatment around 10-15 days, and assembly an additional 10-15 days. The exact duration can vary based on order complexity and quantity, impacting total production time. I’ve learned strategizing with my suppliers 3 helps optimize these phases.

For critical components, improving efficiency in each stage requires close monitoring and coordination 4. This interaction is vital for maintaining streamlined operations and ensuring timely deliverables, as manufacturing bottlenecks often result in costly delays.

Process Breakdown

| Step | Typical Lead Time (Days) |

|---|---|

| Machining | 15-20 |

| Heat Treat | 10-15 |

| Assembly | 10-15 |

I evaluate these factors to anticipate potential delays, which provides a clearer picture of my production timeline. Maintaining transparency with suppliers ensures consistently effective communication.

Do you buffer raw materials to shorten my custom lead times for my undercarriage parts for excavators & bulldozer for excavators & bulldozer?

Raw material availability can disrupt production processes. Buffering them can safeguard against unforeseen delays. At times, uncertainties related to sourcing can complicate schedules.

By buffering critical materials, lead times for custom parts are effectively reduced by 20-30%. It provides flexibility, ensuring production isn’t stalled due to shortages. This strategic approach helps maintain the continuity of my operations 5.

Materials buffer entails stocking essential items like forgings or casting blanks. It enhances adaptability amidst fluctuations and provides the much-needed cushion when demand spikes or supplies dwindle. This proactive measure is a cornerstone in my supply chain strategy 6.

Stock management in production helps alleviate strain during peak times and ensures continuity. This predictability in supply chain aids in planning and prepares me to adapt swiftly to changing business needs.

Can I reserve capacity with rolling forecasts for my orders for my undercarriage parts for excavators & bulldozer for excavators & bulldozer?

Forecasting methods significantly impact operational efficiency. I often emphasize its importance to align production capacity with demand for my components. Accurate predictions ensure seamless operations.

Reserving capacity allows earlier slotting of manufacturing resources dedicated to my orders. It mitigates scheduling conflicts in busy periods and assures timely completion of orders. Insightful planning is paramount.

Regular updates of forecasts facilitates an adaptable production schedule. This flexibility is crucial to adapting to market dynamics, aligning demand with capacity, and preventing potential downtime.

Planning Guide

| Forecast Type | Timeframe |

|---|---|

| Short-Term | 1-3 months |

| Medium-Term | 6 months |

| Long-Term | 1 year |

With a structured approach to rolling forecasts 7, I better manage resources while anticipating changes in demand. It reduces lead time variability and supports operational stability.

Will you commit to ship windows and penalties if late for me for my undercarriage parts for excavators & bulldozer for excavators & bulldozer?

Commitment to ship windows assures reliability. Accountability for timelines is integral to trust-based supplier relationships. Delays can have far-reaching consequences on operations.

Suppliers offer commitments to shipping schedules 8, including penalties for missed deadlines. This ensures priority and adherence to timelines, safeguarding operational flow. I find assurance in structured agreements.

Negotiating penalties enhances dedication to timelines, fortifying supplier accountability. Such arrangements solidify partnerships 9, fostering mutual respect and understanding crucial for successful collaboration.

Transparent communication on shipping commitments assures seamless operations. Planning for contingencies and establishing clear penalties for delays reinforces stability in supply chains and optimizes performance.

Conclusion

Effective planning and supplier partnerships are keys to managing production lead times and ensuring seamless delivery schedules. Consistent evaluation and strategic adjustments help maintain operational excellence.

Footnotes

1. Explore how logistics influence supply chains. ↩︎

2. Understand peak demand forecasting techniques. ↩︎

3. Tips for negotiating effectively with suppliers. ↩︎

4. Guide on supplier quality management practices. ↩︎

5. Learn strategies for business continuity planning. ↩︎

6. Insight into adaptive supply chain strategies. ↩︎

7. Discover the benefits of rolling forecasts. ↩︎

8. Understand transportation management systems in logistics. ↩︎

9. Building effective B2B partnerships in digital era. ↩︎