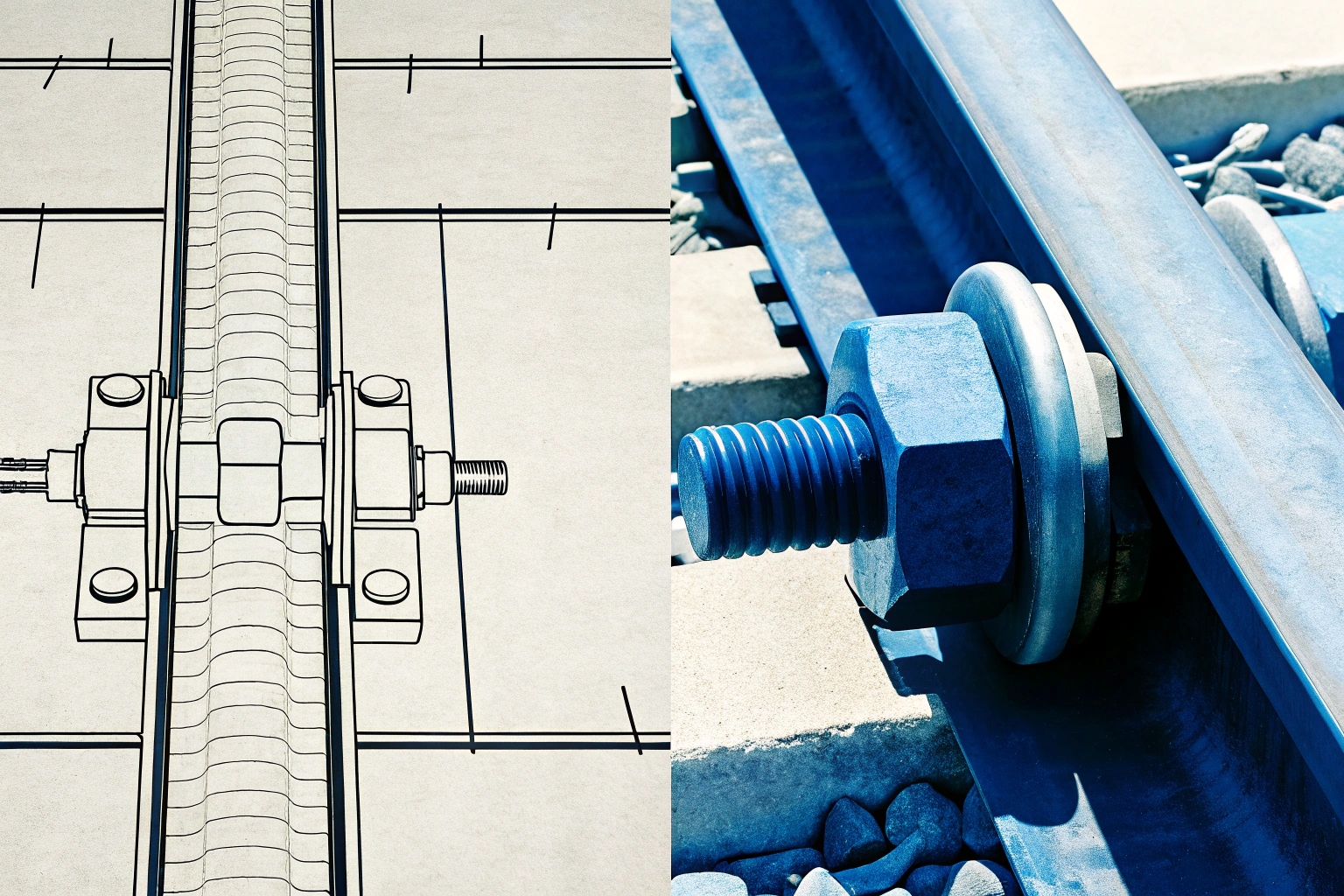

In my exploration of undercarriage parts for excavators & bulldozer 1, the choice of bolt and nut strength grades caught my eye. It’s a problem I see often — bolts loosening due to constant vibration and dynamic loads 2.

Choosing the right bolt and nut strength grades is pivotal to the durability and safety of your undercarriage parts for excavators & bulldozer. Strength grades such as 10.9 and 12.9 are widely used due to their capability to withstand high tension and shear forces. Ensuring the proper selection and application of these components enhances the overall performance and lifespan of the machinery.

It’s easy to overlook the importance of these components, yet they are essential for a stable and efficient system. Let’s discuss the optimal solutions for your needs.

What Bolt and Nut Strength Grades (10.9/12.9) and Anti-Loosening Solutions Can I Use for My Track Shoes for My Undercarriage Parts for excavators & bulldozer?

Choosing the right bolt strength for my undercarriage parts for excavators & bulldozer has always been a balancing act. I realized that constant vibration can easily loosen the fasteners, leading to costly down-time 3 and potential machine failure.

Bolt strength grades 10.9 and 12.9 are best suited for track shoes. Grade 12.9 provides extremely high tensile strength, making it ideal for the intense conditions of undercarriage parts for excavators & bulldozer. Anti-loosening solutions such as wedge-locking washers or thread-locking adhesives add to their reliability, preventing bolt failures under dynamic loads.

Selecting the right combination involves understanding both the strength needs and the functional environment 4 of the machinery. Here’s more on why these solutions work:

Understanding Bolt and Nut Grades

| Strength Grade | Tensile Strength (MPa) | Application |

|---|---|---|

| 10.9 | ~1040 | General machinery components |

| 12.9 | ~1220 | High-stress applications like track shoes |

Grade 10.9: These bolts are generally used for components like sprocket segments 5 and track rollers. While they offer considerable strength, their application in track shoes is limited.

Grade 12.9: Recognized as the industry standard 6 for high-tensile track shoe bolts, these provide the necessary clamping force to withstand severe shear, impact, and vibrational forces.

Anti-Loosening Solutions

Being proactive with anti-vibration and loosening solutions is fundamental:

- Wedge-Locking Washers: Innovative washers designed with cams and radial serrations 7 effectively lock the nut in place, making them ideal for environments subject to heavy vibration.

- Thread-Locking Adhesives: Secure fasteners permanently using anaerobic adhesive like Loctite 8, providing robust locking and sealing capabilities.

Will You Recommend Torque Values and Re-Torque Intervals for My Crews for My Undercarriage Parts for excavators & bulldozer?

Hilary, my maintenance technician, once mentioned how critical torque accuracy and maintenance are. It’s been instrumental in our zero-incident record 9.

Adhering to correct torque values and re-torque intervals for undercarriage parts for excavators & bulldozer maximizes bolt performance. Employing the torque-angle method during installation ensures secure fastening, while regular inspection and re-torque checks sustain optimal tension and prevent failures.

Adopting a systematic approach to installation and maintenance can be a game-changer for equipment longevity.

Precise Torque and Maintenance Guidelines

| Component | Initial Torque (Nm) | Re-Torque Interval |

|---|---|---|

| Track Shoes | 150 | Every 500 hours |

| Rollers | 100 | Every 400 hours |

Using the Torque-Angle Method 10 is vital. This doesn’t just involve tightening to a torque value; it ensures the bolt is stretched to the right degree:

- Clean all surfaces: Remove paint and debris to ensure a solid contact.

- Lubricate as needed: Reduces friction, allowing accurate torque application.

- Initial Snug Torque: Draw components together with an initial low torque.

- Apply Angle of Turn: Further tighten using equipment like a torque-angle gauge to achieve the critical bolt stretch.

Can You Provide Wedge-Lock or Prevailing Torque Nuts for My Safety Needs for My Undercarriage Parts for excavators & bulldozer?

I realized that even well-torqued bolts can loosen without the right fastening technology, impacting safety.

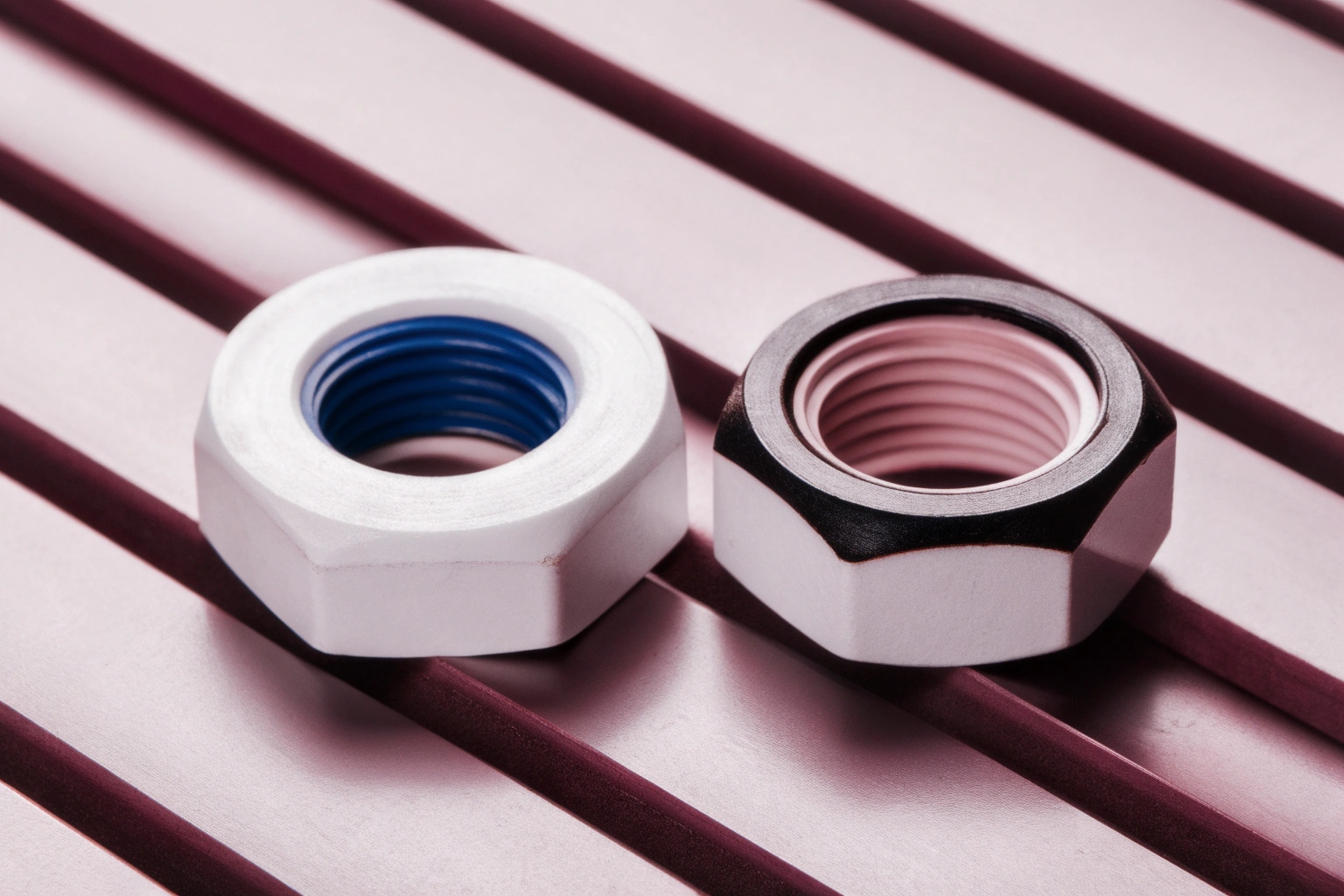

Wedge-lock and prevailing torque nuts are highly effective solutions for maintaining tension and preventing loosening under vibration. They are particularly beneficial for safety-critical applications where reliability and structural integrity are paramount.

For demanding environments, selecting the right locking mechanism is crucial.

Wedge-Lock vs. Prevailing Torque Nuts

| Type | Mechanism | Best Used For |

|---|---|---|

| Wedge-Lock Nuts | Pair with cam and serration mechanism | High-vibration environments |

| Prevailing Torque Nuts | Additive features impede loosening | General industrial use |

Wedge-Lock Nuts: Their unique cam design increases friction as tension rises, locking the fastener firmly in place. They are ideal for high-stress applications that demand repeated reliability.

Prevailing Torque Nuts: By integrating features like deformed threads or nylon inserts, these nuts create resistance not dependent on bolt tension alone, suitable for varied applications where ease of maintenance is necessary.

Do You Supply Threadlocker and Washers Matched to My Spec for My Undercarriage Parts for excavators & bulldozer?

A dependable fastening system has always been a top priority. Threadlockers and washers should match machine specifications for ideal performance.

Specifically matched threadlocker and washers ensure an integrated fastening system. Employing them prevents thread rust, reduces maintenance downtime, and complements the bolt and nut grades, providing comprehensive security.

A synchronized choice extends equipment usability and security.

Choosing the Right Threadlocker and Washers

- Threadlockers (e.g., Loctite 271): They fill thread voids, preventing rust and maintaining tension.

- Washers: Fit and material meeting application needs, ensuring load distribution and surface protection.

Be sure to consult manufacturer specs to ensure optimal matching, catering not only to operational needs but also to specific environmental factors affecting performance.

Conclusion

Choosing the ideal bolt, nut, and anti-loosening solutions ensures that your undercarriage parts for excavators & bulldozer perform reliably under stress. Proper torque application and maintenance only bolster these efforts, securing machinery for optimal operation.

Footnotes

1. Overview of common heavy machinery undercarriage components. ↩︎

2. Learn how dynamic loads and vibration affect structural integrity. ↩︎

3. Strategies for reducing equipment downtime in heavy industry. ↩︎

4. How environmental conditions impact machine design and material choice. ↩︎

5. Details on the function and types of sprocket segments. ↩︎

6. Overview of ASTM and ISO standards for industrial fasteners. ↩︎

7. See how wedge-locking cam mechanisms prevent loosening. ↩︎

8. Guide to using anaerobic threadlockers for bolt security. ↩︎

9. Information on implementing safety management systems for zero incidents. ↩︎

10. Technical guide to the torque-angle method for bolt tightening. ↩︎