The difference between carrier rollers and track rollers lies in their position and function within the excavator’s undercarriage 1. While carrier rollers are positioned on top, supporting the track’s tension 2, track rollers are located below and carry the excavator’s weight. Watching out for wear resistance 3 and material quality is essential when buying these components.

Carrier rollers are found atop the undercarriage frame and mainly support the track’s upper section, aiding in tension maintenance. Track rollers are placed underneath, bearing the excavator’s weight and assisting movement across the track chain 4. Understanding these differences helps make informed purchasing decisions, ensuring compatibility and durability.

When choosing rollers, prioritize high-quality seals 5 to secure lubrication and block contaminants. Additionally, attention to compatibility with your specific excavator model and understanding the material quality are crucial aspects to consider. These components require regular maintenance 6 to avoid mishaps, making these considerations essential for long-term functionality.

How do I confirm carrier roller dimensions and mounting type?

Confirming carrier roller dimensions and mounting type involves measuring the current rollers and using the excavator’s specifications. Overlooking this can result in mismatched parts and operational issues, so precise measurement and proper specification adherence are crucial.

The dimensions of carrier rollers are best confirmed by measuring existing components or consulting excavator model specifications 7. Mounting types, which vary, are determined based on the excavator design. Failing to match these elements correctly leads to incompatibility issues, affecting machine efficiency.

Peer into the details by examining roller specifications. Understand the mounting types 8, usually either bolt-on or weld-on, which dictate installation methods. Ensure dimensions match, including diameter and width, which are pivotal for fitment and functionality. Failure to align these specs with the excavator model can lead to operational hindrance and premature wear.

Mounting Types Table

| Mounting Type | Description | Example |

|---|---|---|

| Bolt-On | Attached using bolts | Caterpillar D-Series |

| Weld-On | Requires welding for installation | Komatsu PC-Series |

Key Measurements Table

| Measurement | Purpose | Requirement |

|---|---|---|

| Diameter | Ensures fit | Model-specific |

| Width | Provides support | Track alignment |

Understand these aspects through technical specifications. Carrier roller dimensions vary by model, typically smaller than track rollers to streamline guidance. Accurate specification adherence avoids operational inefficiencies and enhances performance.

Do my carrier rollers require specific seal brands or types?

Carrier rollers require specific seal brands and types to ensure longevity and optimal performance. Selecting inferior seals might lead to premature damage and inefficiencies in the roller systems, highlighting the importance of choosing high-quality seals.

Carrier rollers depend on specialized seals for effective functionality. These seals act like barriers, preventing contaminants like dirt, water, and mud from entering and compromising the roller’s operations. Without proper seals, carriers might face accelerated wear, affecting the track’s tension maintenance.

Seal brands and types vary, with duo-cone seals 9 being popular for effectiveness. Evaluate brands offering longevity and robust protection, preventing contaminant entry. Investing in recognized seal brands enhances reliability and performance, maintaining undercarriage integrity.

Seal Types Table

| Seal Type | Features | Common Use |

|---|---|---|

| Duo-Cone | High-quality sealing | Excavator rollers |

| Floating | Effective in isolation | Industrial applications |

Establish understanding in choosing seal types with consideration for environmental conditions. High-pressure seals provide robust defense against harsh conditions where carrier rollers operate. Seal failure results in contaminant entry, leading to wear and performance inefficiencies.

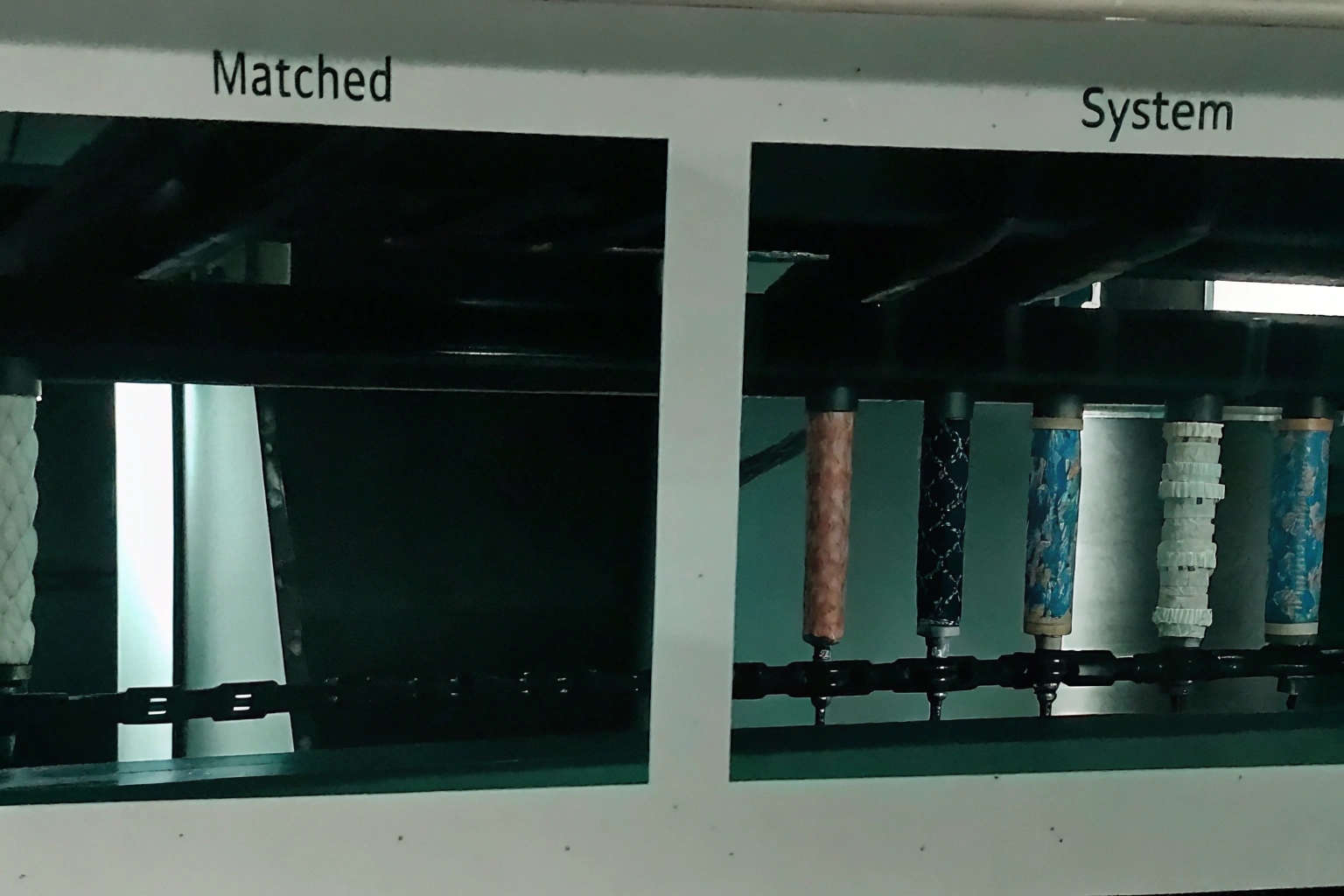

Can I mix carrier and track rollers from different manufacturers?

Mixing carrier and track rollers from different manufacturers can lead to compatibility issues. The differences in manufacturing processes affect performance, necessitating caution and thorough compatibility checks before mixing components.

Carrier and track rollers differ not only by function but by manufacturer-specific design nuances. Each manufacturer adheres to unique specifications, influencing roller compatibility and overall performance. Relying solely on general sizing risks mismatches and performance reductions.

Delve deeper into mixing roller brands. Examine any colors representing differences in quality or compositional materials. Compatibility is a primary concern when considering mixing brands, as unique manufacturing processes can impact wear resistance and operational fluidity.

Compatibility Requirements Table

| Factor | Importance | Example |

|---|---|---|

| Material | Affects durability | High manganese steel |

| Design | Influences fitment | Manufacturer specs |

Understand differences when considering mixing components. While visually similar, the chemical composition and manufacturing process of rollers from different brands vary, affecting the synergy of components within the undercarriage framework. Compatibility mismatches can stress systems, resulting in accelerated wear or failures.

What lubrication specs should my rollers meet?

Roller lubrication specs are crucial for their performance and longevity. Selections should meet the environmental and operational demands of the excavator to ensure smooth, efficient operation free of unnecessary friction and wear.

Roller lubrication requires specific specifications matching environmental conditions 10. Without appropriate specifications, lubrication fails to prevent wear, hindering operation life and efficiency. Understanding and ensuring adherence to these requirements bolsters roller functionality.

Dive further into lubrication needs, discriminating between various environments where rollers operate. High-temperature or high-stress situations require tailored lubrication solutions, vital for smooth function and component preservation.

Lubrication Specs Table

| Spec Type | Characteristics | Use case |

|---|---|---|

| Viscosity | Determines fluidity G | Extreme temperatures |

| Additives | Enhances properties | Moist environments |

Confirm lubrication meets operational needs. Examine each specification’s application, including viscosity suitable for temperature fluctuations. Such considerations enable continued roller operation under diverse conditions, preventing premature component wear.

Conclusion

Carrier and track rollers play distinct roles in the excavator’s function, with careful consideration in dimensions, seal types, and compatibility ensuring optimal performance. Ensuring proper lubrication enhances longevity and operational efficiency.

Footnotes

1. Overview of the components and function of an excavator undercarriage. ↩︎

2. Guide on how to properly check and adjust excavator track tension. ↩︎

3. Explanation of material properties that contribute to heavy machinery wear resistance. ↩︎

4. Detailed look at the components of a track chain assembly. ↩︎

5. Importance of sealing solutions in protecting heavy equipment bearings. ↩︎

6. Checklist for performing regular maintenance on excavator undercarriages. ↩︎

7. How to find and read OEM specifications for your excavator model. ↩︎

8. Comparison of bolt-on versus weld-on undercarriage components. ↩︎

9. Technical data and benefits of using duo-cone seals in heavy machinery. ↩︎

10. How factors like temperature and moisture affect lubrication requirements. ↩︎