Returning parts can be a real hassle, especially when dealing with international shipping logistics 1. I’ve personally had my fair share of frustration with RMA processes 2 and the associated costs that come with them.

The process typically starts with contacting the seller to obtain a Return Material Authorization (RMA) number. The logistics cost, however, generally falls on the buyer unless the return policy states otherwise.

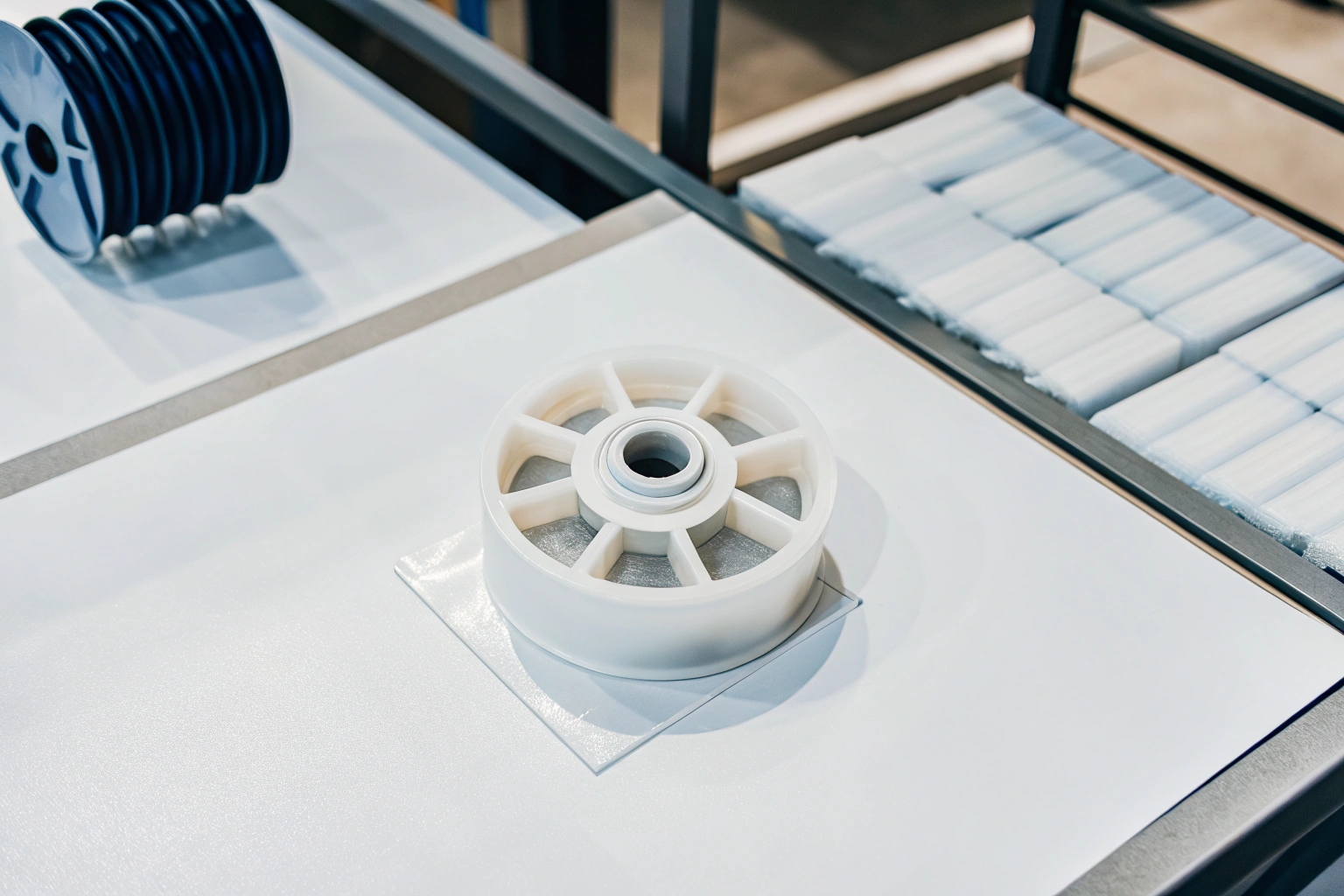

Understanding the nuances of the return process for undercarriage parts for excavators & bulldozer is crucial, especially when dealing with suppliers based in China 3. Let’s dive into the specifics of what you need to know.

Do I need a Return Material Authorization (RMA) number before sending anything back?

I’ve been in situations where missing an RMA number delayed my returns significantly. It’s frustrating to deal with such setbacks and lose valuable time.

Yes, before returning any parts, it’s essential to obtain an RMA number from the seller. This number is crucial for tracking the return efficiently and ensuring the supplier’s compliance with its return policy.

How to Get an RMA Number

| Step | Description |

|---|---|

| 1 | Initial Contact with Seller |

| 2 | Provide Proof of Purchase |

| 3 | Submit Photographic Evidence of Defects |

| 4 | Receive RMA Number and Return Instructions |

Having an RMA number is not just a requirement; it’s a crucial step in tracking the return efficiently 4 and ensuring the supplier’s compliance with its return policy 5.

Who pays for the return shipping if the part is defective under warranty?

When dealing with defective parts under warranty 6, nothing angers more than discovering you’re stuck with high shipping fees. I’ve been there, and it’s not fun.

If parts are defective under warranty, typically the seller covers the return shipping costs. However, it’s essential to verify this within their specific return policy.

Return Shipping Responsibilities

| Situation | Shipping Cost Responsibility |

|---|---|

| Defective Parts Under Warranty | Seller |

| Non-Defective Buyer Mistake | Buyer |

| "Item Not As Described" (INAD) | Seller |

Understanding these policies ensures you’re not overburdened with unexpected costs and disruptions.

If I ordered the wrong part by mistake, can I return it and what is the restocking fee?

Making a mistake in ordering can be quite a headache. I’ve had mix-ups with parts, and the aftermath taught me valuable lessons about return policies 7.

Yes, you can return wrongly ordered parts, but expect to pay a restocking fee. This fee typically ranges between 20-30% of the part’s cost.

Restocking Fee Details

| Restocking Fee | Conditions |

|---|---|

| 20-30% | Applied for ordering errors |

| Original Packaging Required | Parts must be in original condition |

Ordering errors should not be overly punitive, yet they often are.

Is it possible to get a credit note instead of shipping the part back?

Choosing between a return and a credit note can be daunting. I’ve often had to weigh these options and consider what’s more beneficial financially and logistically.

Yes, some sellers offer a credit note as an alternative to returning parts, especially when logistics are complex or costs are high. Negotiating alternatives can save you money and hassle.

Credit Note vs Return

| Option | Advantages |

|---|---|

| Credit Note | Avoids hefty shipping fees; flexible future use |

| Return | Refund processing; may involve restocking fees |

Embracing such solutions can make the return process less financially burdensome.

Conclusion

In conclusion, navigating the RMA process involves a series of strategic steps: securing an RMA number, understanding who pays for logistic fees 8, being aware of restocking policies 9, and considering alternatives like credit notes 10. These clarify your role and responsibilities in dealing with undercarriage returns.

Footnotes

1. Guide on managing international shipping logistics for B2B returns. ↩︎

2. Learn the standard steps of a Return Material Authorization (RMA) process. ↩︎

3. Tips for navigating business and return policies with Chinese suppliers. ↩︎

4. Best practices for efficiently tracking international return shipments. ↩︎

5. How to ensure supplier compliance with stated return policies. ↩︎

6. Guide to understanding and managing defective parts under a warranty claim. ↩︎

7. Key elements to check for in a supplier’s return policy. ↩︎

8. How to calculate and manage international logistic fees for heavy parts. ↩︎

9. Explanation of what restocking policies cover and average B2B rates. ↩︎

10. Learn how credit notes function as an alternative to refunds in B2B transactions. ↩︎