In my work with heavy machinery, I’ve often faced challenges with track guards and wear plate configurations. These components are crucial for the undercarriage parts for excavators & bulldozer of equipment. Ensuring their durability and maintenance is vital for cost-efficiency and operational uptime.

Choosing materials like high-strength steel 1 for track guards is essential for durability. ABRASION-RESISTANT (AR) steel 2 is commonly used for wear plates due to its longevity against harsh conditions. For more extreme environments, tungsten carbide overlay plates 3 offer superior wear protection. They come in various configurations such as flat, curved, or custom-shaped to match specific equipment specifications. Use replaceable liners 4 for easy maintenance which extends service life.

By considering the specific needs of each machine model, one can ensure an optimal fit and performance through customizable configurations. The installation flexibility with bolt-on and weld-on options 5, combined with the modular design, minimizes downtime during replacements. These diverse choices of materials and configurations address both operational requirements and environmental challenges.

Will you suggest liner materials optimized for my abrasive ground for my undercarriage parts for excavators & bulldozer?

Dealing with abrasive grounds has always been a tough challenge. I understand how crucial it is to have the right liner materials for undercarriage parts for excavators & bulldozer to prevent excessive wear and tear. It’s a challenge I often encounter.

Opting for materials like rubber, polyurethane, or composite materials 6 for liners can significantly enhance wear resistance. These materials are specially designed to combat abrasive environments and extend the service life of your equipment.

Understanding the benefits of selecting the right materials is essential when dealing with abrasive conditions:

Material Differences

| Material | Benefits | Ideal Conditions |

|---|---|---|

| Rubber | Flexibility, Noise Reduction | Moderate Abrasion, Shock Loads |

| Polyurethane | Excellent Abrasion Resistance | High Abrasion, Chemical Exposure |

| Composite | Balance of Cost and Performance | Cost-sensitive Environments |

Having the correct liner ensures optimal performance by reducing downtime and enhancing efficiency. Rubber is known for its flexibility and noise reduction in applications where moderate abrasion or shock loads are present. On the other hand, Polyurethane offers excellent resistance to high-abrasion environments, including chemical exposure. Composite materials provide an ideal balance for cost-sensitive environments.

Can I order bolt-on liner kits to simplify my maintenance for my undercarriage parts for excavators & bulldozer?

Maintenance can be a time-consuming task, especially when dealing with track guard components. I always look for ways to simplify this process, and bolt-on liner kits 7 are a practical solution.

Yes, bolt-on liner kits can simplify maintenance tasks. These kits are designed to make the process more straightforward and efficient for those handling undercarriage parts for excavators & bulldozer.

Transitioning to products like bolt-on liner kits provides many benefits:

Simplified Maintenance Process

- Flexibility in Installation: Operators can quickly replace worn liners without extensive tools, reducing downtime.

- Durability and Adaptability: Bolt-on kits come in various configurations, allowing operators to choose according to specific machine needs.

- Cost Efficiency: Modular design aids in reducing the cost of repetitive replacements, saving on operational expenses.

These kits streamline the entire maintenance process, promoting fast replacements and lessening equipment downtime, ensuring all operations run smoothly.

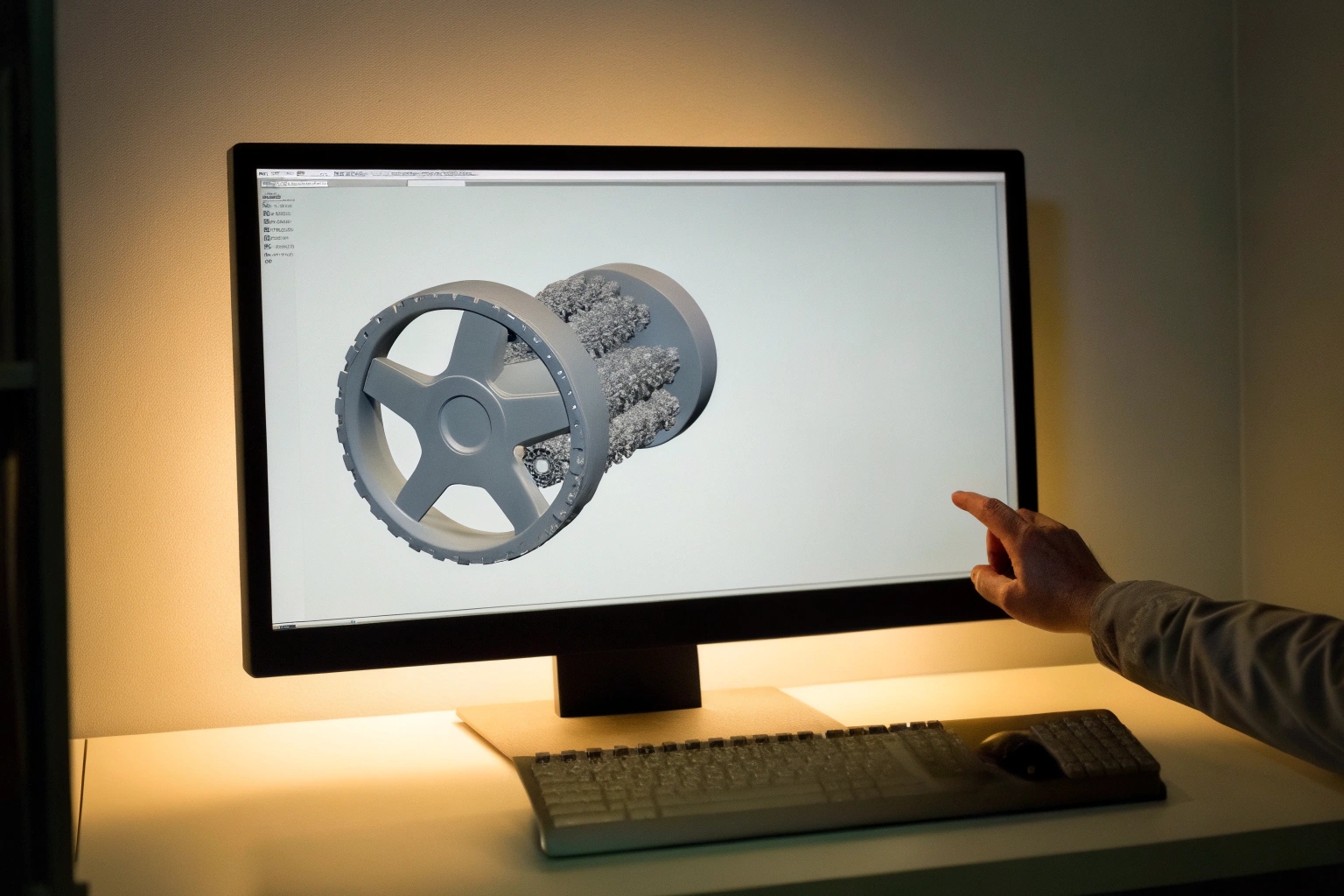

Do you provide CAD drawings so I can check clashes on my machines for my undercarriage parts for excavators & bulldozer?

During numerous projects, I’ve realized the importance of having precise CAD drawings 8. These drawings help me check for potential clashes on machinery before any installation steps in undercarriage parts for excavators & bulldozer management.

Providing CAD drawings ahead of installation helps users identify clashes and ensure the perfect fit for their machinery’s undercarriage components.

Going deeper into the subject:

Importance of CAD Drawings

CAD drawings are highly beneficial, especially for those customizing their equipment setup:

| Benefit | Purpose |

|---|---|

| Clarity | Visualize parts and their placement |

| Accurate Fit | Assure measurements align with various machinery |

| Error Minimization | Reduce the potential risk of mishaps during installation |

These drawings ensure optimal arrangements by enabling visibility and decision-making in advance. It’s an investment in quality assurance, precision, and seamless compatibility, keeping projects on track without unnecessary interference.

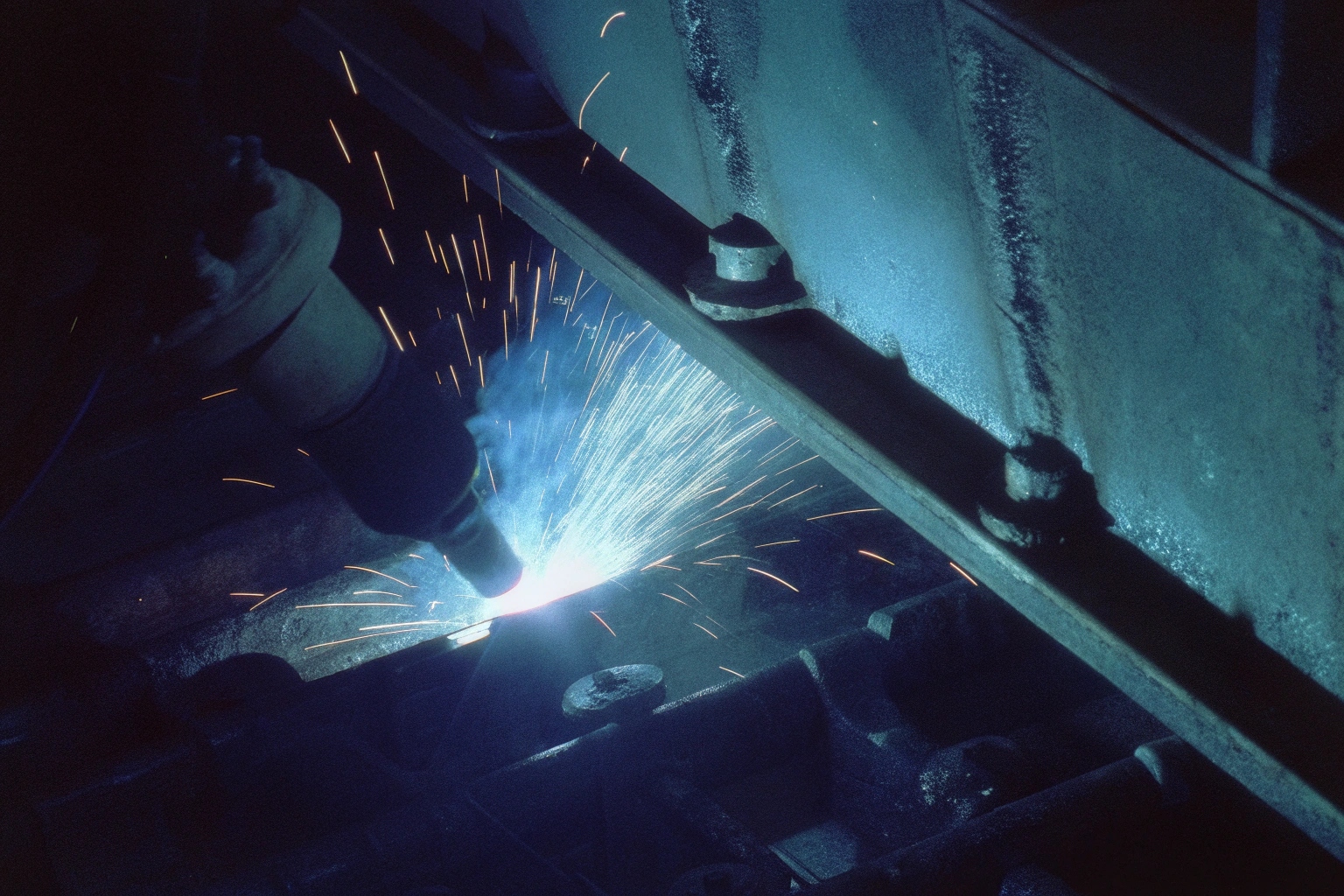

Can I request hardfacing on critical wear zones for my guards for my undercarriage parts for excavators & bulldozer?

In high-wear zone applications, hardfacing 9 can be essential. I’ve found it to be a valuable step for enhancing durability and reducing wear and tear.

Yes, requesting hardfacing on critical wear zones is possible to increase the durability of undercarriage parts for excavators & bulldozer significantly.

Understanding hardfacing’s importance:

Benefits of Hardfacing

Hardfacing improves the longevity of components and reduces frequent replacements:

| Aspect | Impact |

|---|---|

| Durability | Extends life of high-wear components |

| Resistance | Increases protection against abrasion and impact |

| Maintenance Reduction | Decreases frequency and cost of part replacements |

The implementation of hardfacing introduces a protective layer on critical zones, ensuring that components withstand challenging environments and continue to function optimally across projects.

Conclusion

The right materials, configurations, and maintenance strategies for track guards can noticeably impact your machinery’s efficiency and life span.

Footnotes

1. Explore high-strength steel options for durability. ↩︎

2. Learn about abrasion-resistant steel benefits. ↩︎

3. Understand tungsten carbide overlay advantages. ↩︎

4. Guide to using replaceable liners for maintenance. ↩︎

5. Compare bolt-on versus weld-on configuration benefits. ↩︎

6. Select ideal liner materials for abrasive conditions. ↩︎

7. Benefits of using bolt-on liner kits for maintenance. ↩︎

8. The role of CAD drawings in equipment customization. ↩︎

9. Advantages of hardfacing in high-wear applications. ↩︎