When I first delved into the world of undercarriage parts for excavators & bulldozer 1, the complexity and variety of track shoe options caught me off guard. It was overwhelming, yet exciting.

Track shoe materials, thicknesses, and hardness ranges are designed to meet diverse operational demands. They incorporate high-strength alloy steels like 25MnB, 35MnB, and 50Mn. Thickness options range from 10 mm to 40 mm, and hardness spans from 350 to 550 HB. Rock-duty shoes offer reinforced durability, while abrasion-resistant varieties reduce wear with specialized coatings.

Understanding the vast options available requires some technical knowledge. Below, I’ll break down key specifications and choices to fit various needs.

Can you propose shoe designs tailored to my clay vs rocky sites for my undercarriage parts for excavators & bulldozer?

The first time I dealt with different terrains, shoe design seemed daunting. But knowing that tailored solutions exist made everything clearer.

Designs for clay and rocky terrains differ in grouser configurations and materials. Clay-specific designs offer single or double grousers for improved traction and minimized soil compaction. Rocky terrain shoes focus on thicker plates and high-strength materials to withstand abrasive impacts. Tailored solutions ensure optimized performance across diverse sites.

The choice of shoe design depends largely on the environment it will operate in. For instance, in clay-heavy sites, slip resistance and minimized soil compaction 2 are priorities. Therefore, shoes designed with wider grousers and reduced penetration are ideal. Contrarily, rocky terrains demand shoes that can endure constant abrasion and impact. Here, fortified materials with thicker plates improve durability.

H3: Material Considerations

Rock shoes typically utilize boron-manganese alloy steel 3 due to its impact resistance. Conversely, clay shoes may prefer a lower hardness alloy to avoid excessive soil perforation. Manufacturers like Sandrock Mining offer varied designs, from single to triple grouser shoes 4, to cater to terrain-specific needs. Their range includes standard and extreme service shoes to match different operational conditions.

H3: Comparative Designs

Here’s a comparison of clay and rocky terrain shoe designs:

| Feature | Clay Terrain Shoes | Rocky Terrain Shoes |

|---|---|---|

| Grouser Design | Single/Double | Triple |

| Material | Moderate hardness alloy | High-strength alloy |

| Plate Thickness | Standard (~10 mm) | Thickened (12.5 mm+) |

| Durability Focus | Soil compaction | Abrasion and impact |

| Available Options | Wider, softer grousers | Reinforced taller grousers |

Choosing between these designs involves assessing site conditions and operational requirements to ensure optimal machine performance.

Early on, I learned that data transparency is crucial. It builds trust and ensures informed decision-making.

Yes, bending and fatigue test data are essential for evaluating the durability of heavy-duty shoes. They include results on material stress resistance and lifecycle expectations. Transparent data sharing enables informed decisions and confirms adherence to stringent quality standards.

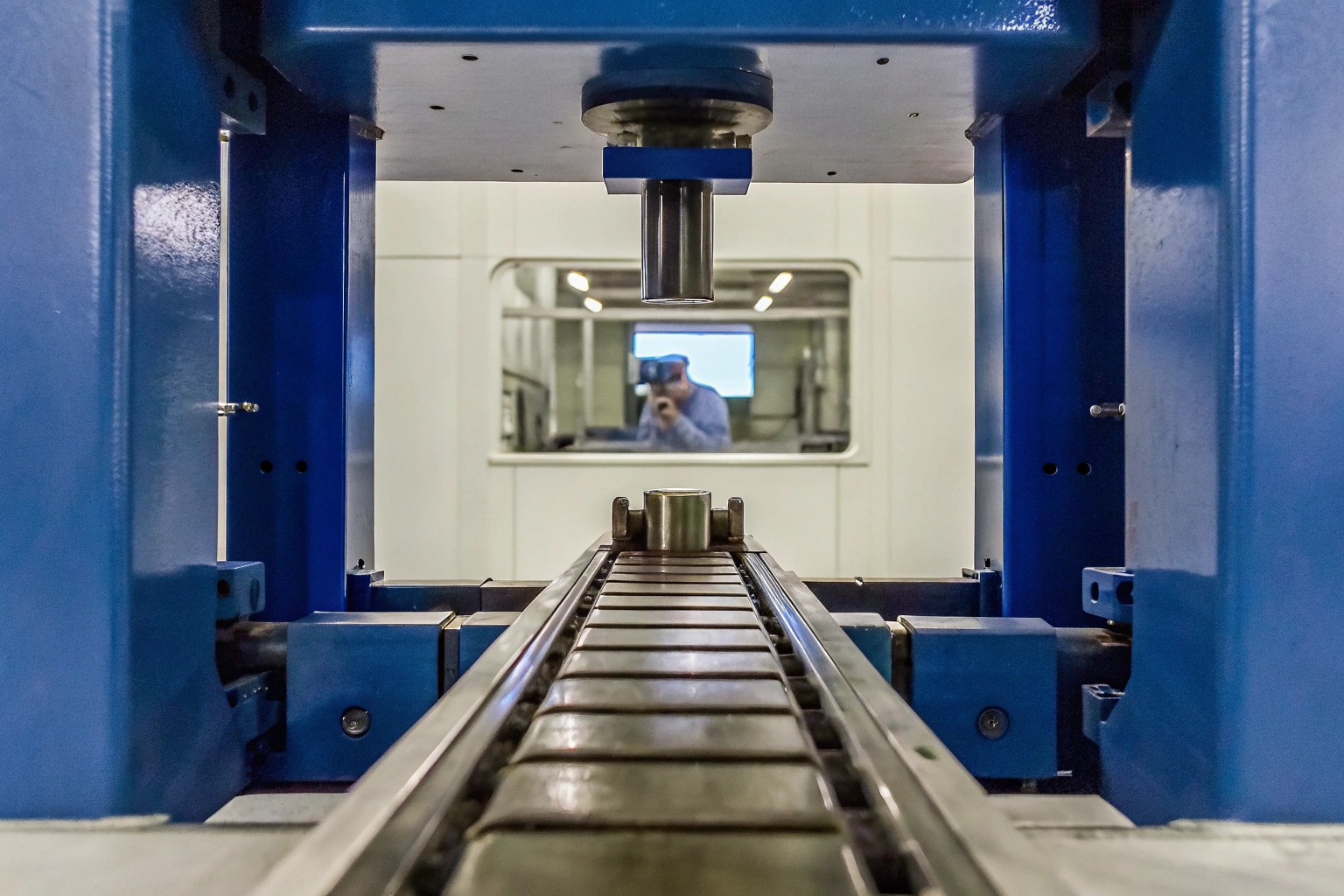

Industries prioritize durability, especially for heavy-duty applications. Tests such as bending and fatigue evaluations 5 reveal real-world performance metrics.

H3: Testing Protocols

- Bending Test: Assesses the shoe’s resistance to deformation under pressure. It’s critical for applications facing high load variations.

- Fatigue Test: Evaluates the shoe’s longevity under repeated stress. Essential for determining wear life under cyclical loads.

H3: Importance of Data

Publishing test results reassures clients about a product’s reliability. Machines operating under extreme conditions benefit massively from reinforced durability data 6.

| Test Type | Key Measurements | Typical Results for HD Shoes |

|---|---|---|

| Bending Test | Maximum pressure before deformation | >35N/mm² |

| Fatigue Test | Cycle count before failure under specified load | Over 3 million cycles |

| Hardness Test | Surface resistance to penetration | 43 HRC to 58 HRC |

Understanding the implications of such data helps plan maintenance and preempt parts’ replacements, leading to operational efficiency.

Can I request extra gussets or reinforced pads for my fleet for my undercarriage parts for excavators & bulldozer?

I remember the first time I learned about reinforced pads, it felt like a secret weapon against wear and tear.

Yes, you can request additional gussets or reinforced pads to bolster track shoe durability for your fleet. Custom options like these enhance load distribution and impact resistance, extending the life of undercarriage components in rigorous conditions.

Customized reinforcement options, such as gussets or reinforced pads 7, significantly elevate the structural integrity of track shoes 8.

H3: Benefits of Gussets and Reinforcements

- Enhanced Load Distribution: Reduces localized stress, preventing premature wear.

- Improved Impact Resistance: Protects against sharp object penetration and high-pressure contact.

- Extended Service Life: Critical for fleets operating in severe conditions or demanding positions.

H3: Specifications and Configurations

For custom reinforced shoes:

| Feature | Standard Shoes | Reinforced Shoes |

|---|---|---|

| Presence of Gussets | Optional | Mandatory |

| Pad Enhancement | Standard | Reinforced with additional support |

| Core Advantage | Basic durability | Superior resilience and longevity |

Investing in reinforced solutions for your fleet not only prolongs machinery lifespan but also curtails operational downtime, resulting in cost savings over time.

Do you stock common sizes to shorten my lead time for my undercarriage parts for excavators & bulldozer?

I once faced significant delays due to custom part orders. Knowing common sizes are stocked eased many operational worries.

Yes, stocking common track shoe sizes minimizes lead times. Ready availability ensures quick replacements and uninterrupted operations. Continuing partnerships with suppliers further optimizes inventory management, reducing downtime significantly.

Stocking practices play a pivotal role in ensuring operational continuity, especially for machines requiring specific part replacements on short notice.

H3: Common Sizes Overview

Common sizes cover a broad range of machines from excavators to bulldozers:

| Machine Type | Common Size Range (Width x Length) | Typical Application |

|---|---|---|

| Bulldozer | 510 mm x 130 mm to 760 mm x 170 mm | Heavy-duty earth moving |

| Excavator | 500 mm x 110 mm to 700 mm x 150 mm | Moderate to high payload tasks |

| Compact Loader | 300 mm x 70 mm to 350 mm x 100 mm | High maneuverability applications |

H3: Inventory and Supply Chain Management

A well-maintained inventory ensures rapid delivery when needed most, fostering trust and reliability in your parts supply chain 9. Predictive stocking, aligned with market demand, vastly decreases potential delays, keeping your operations smooth and efficient 10.

Conclusion

Selecting the right track shoes involves understanding material, design, and operational needs. Tailored and readily available options enhance machine performance and longevity.

Footnotes

1. Overview of heavy machinery undercarriage components and their functions. ↩︎

2. Learn techniques and equipment designs that reduce ground pressure. ↩︎

3. Properties and benefits of boron-manganese steel in heavy-duty applications. ↩︎

4. Learn how triple grouser shoes balance traction and maneuverability. ↩︎

5. See examples of industry-standard testing procedures for material durability. ↩︎

6. Learn how test data confirms durability for extreme operating conditions. ↩︎

7. Visual examples and benefits of reinforcing track shoes for extreme conditions. ↩︎

8. Best practices for improving the structural integrity of track shoes. ↩︎

9. Strategies for optimizing a heavy equipment parts supply chain. ↩︎

10. Tips for streamlining fleet operations and improving overall efficiency. ↩︎