I know how frustrating it is to see a fresh set of bucket teeth wear down to nubs in a week or, worse, snap off the moment they hit hard rock. You are likely trying to figure out why some parts last months while others fail immediately, and the secret almost always lies in the metallurgy 1.

To get the best lifespan, you generally need low-alloy steel (like 42CrMo) for standard earthmoving and Nickel-Chromium-Molybdenum alloys for high-impact mining. The ideal hardness target is a gradient: HRC 50–58 at the tip for wear resistance, tapering to HRC 38–45 at the root to ensure toughness.

Let’s dig into the specific chemical compositions 2 and heat treatment secrets that separate premium parts from scrap metal, so you can stop wasting money on downtime.

Do I need Ni-Cr-Mo alloy for severe impact?

You might be wondering if paying the premium for Nickel-Chromium-Molybdenum (Ni-Cr-Mo) alloy is just a marketing gimmick or if it is a technical necessity for your specific job site.

Yes, if you are operating in mines or blasting zones, Ni-Cr-Mo alloy is essential because it offers superior deep hardenability and impact toughness. Unlike standard carbon steel, which becomes brittle when hardened, this alloy absorbs heavy shock loads without fracturing, preventing catastrophic tooth loss.

When I talk to clients about "impact," I often use the analogy of glass versus rubber. Standard high-carbon steel can be made very hard—like glass—but if you hit it with a hammer, it shatters. In the excavation world, "shattering" means a tooth snapping off at the shank, leaving your adapter exposed and stopping your machine instantly. This is where the specific chemistry of Ni-Cr-Mo comes into play. It allows us to produce a steel that is hard enough to cut rock but "rubbery" enough internally to absorb the shock of the hit.

In my years of manufacturing at Dingtai, I have seen a clear divide in material performance. For standard construction—digging dirt, clay, or loose gravel—a standard low-alloy steel like 42CrMo (similar to AISI 4140) is fantastic. It is cost-effective and wears well. However, the moment you move to a quarry or a mine with blasted rock, 42CrMo starts to show its weakness. It lacks the "through-hardening" capability of Nickel alloys.

The Role of Chemical Elements

To understand this better, you have to look at what each element adds to the "soup" of the molten steel. It is not just about melting iron; it is a precise chemical recipe:

- Carbon (C): The primary hardener. More carbon means harder steel, but also more brittleness. It is a double-edged sword.

- Chromium (Cr): Adds wear resistance and corrosion resistance. It helps the "shell" stay hard against abrasive sand.

- Molybdenum (Mo): This is critical for maintaining strength at high temperatures and increasing the depth of hardness. Without Molybdenum 3, the center of a thick tooth stays soft.

- Nickel (Ni): This is the magic ingredient for toughness. It improves the steel’s impact strength, especially at lower temperatures.

Cost vs. Value Analysis

I recently worked with a client, let’s call him David, who manages a fleet for a large distributor in the US. He was buying standard alloy teeth to save about 15% on the unit price. However, his end-users in Nevada mines were reporting a 5% breakage rate. That might sound low, but 5% breakage meant downtime every other day. We switched him to a Ni-Cr-Mo alloy. The unit price went up, but the breakage rate dropped to zero.

Here is a comparison of how these materials stack up in real-world applications:

| Material Class | Key Alloy Elements | Best Application | Impact Rating | Wear Rating | Relative Cost |

|---|---|---|---|---|---|

| Carbon Steel | C, Mn | Sand, Loam, Agriculture | Low | Low | $ |

| Low Alloy (42CrMo) | Cr, Mo | Construction, Roadwork, Gravel | Medium | High | $$ |

| Ni-Cr-Mo Alloy | Ni, Cr, Mo | Mining, Quarrying, Blasted Rock | Very High | Very High | $$$ |

If your fleet faces severe impact, the "expensive" alloy is actually the cheapest option because it keeps the machine running. You are not just paying for metal; you are paying for the guarantee that the tooth stays on the bucket.

What HRC range balances toughness and wear?

There is a common misconception that "harder is always better," but in the world of ground engaging tools 4 (G.E.T.), excessive hardness is often the primary cause of premature failure.

The ideal hardness range balances wear life and structural integrity, typically landing between HRC 47 and 55. We recommend a "differential hardening" approach: HRC 50–58 at the tip to slice through abrasive material, and HRC 45–50 in the body to support the load.

Achieving the perfect hardness is a balancing act. If the steel is too soft (below HRC 45), it acts like butter against sandpaper—it just wears away too fast, costing you money in frequent replacements. If it is too hard (above HRC 58 or 60), it becomes prone to brittle fracture 5. I have seen high-hardness teeth explode into pieces just from being dropped on the shop floor, let alone hitting a granite wall.

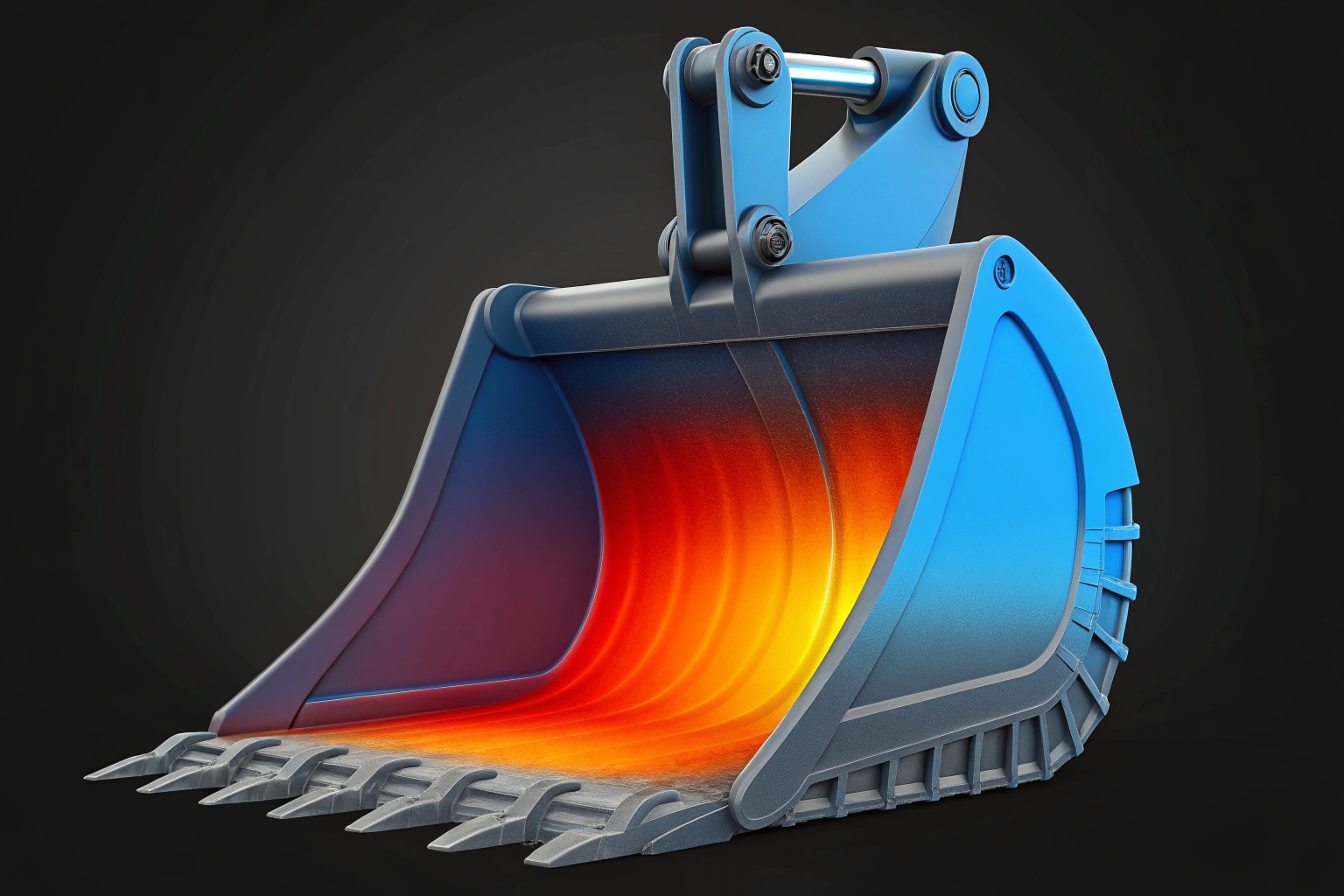

The Concept of Differential Hardening

The solution we use in the factory is called differential hardening or "zoning." We do not treat the entire tooth to the same hardness level. The heating and quenching process is controlled so that different parts of the tooth have different properties. This process mimics the natural structure of a human tooth: hard enamel on the outside, softer dentin on the inside.

Hardness Zones Explained

- The Tip (The Cutting Edge):

- Target: HRC 50–58.

- Function: This area encounters the most friction. It needs to be as hard as possible to resist abrasion. We often use higher carbon content or specialized heat treatment here to maximize the "wear volume."

- The Body (The Structure):

- Target: HRC 45–50.

- Function: This is the muscle. It transfers the breakout force from the machine to the tip. It needs a blend of hardness and tensile strength 6.

- The Root/Shank (The Connection):

- Target: HRC 38–45.

- Function: This is critical. This part wraps around the adapter and holds the pin. If this area is too hard (e.g., HRC 55), the stress from the pin will crack the mounting ear. It must be ductile (stretchy) enough to flex slightly under load without cracking.

Environmental Adjustments

Another factor I always discuss with my international clients is the operating temperature. Steel behaves differently in the freezing cold. For my clients in Russia or Northern Canada, where temperatures drop below -30°C, we deliberately lower the target hardness by 2–3 HRC.

Why do we make them softer? Because cold makes steel brittle. By tempering the steel to be slightly softer (say, HRC 48 instead of 52), we increase the impact toughness to compensate for the freezing conditions. It is a subtle metallurgical adjustment that prevents winter snapping issues.

Hardness Targets by Material Type

Different soil types demand different hardness strategies. Here is how we adjust targets based on what you are digging:

| Application | Rec. Tip Hardness (HRC) | Rec. Root Hardness (HRC) | Priority Factor |

|---|---|---|---|

| Sand / Abrasive Soil | 53 – 58 | 40 – 45 | Max Abrasion Resistance |

| General Construction | 48 – 52 | 38 – 42 | Balanced Performance |

| Hard Rock / Mining | 47 – 50 | 35 – 40 | Max Impact Toughness |

If you are buying teeth, ask your supplier about these zones. If they tell you the tooth is "HRC 55 all the way through," be careful—that is a recipe for a broken shank.

Can I request impact and abrasion test reports?

You should never rely solely on a salesperson’s promise regarding quality; in this industry, paper trails and lab data are the only things that separate premium manufacturers from low-quality workshops.

Absolutely, you have every right to demand third-party test reports. You should specifically ask for Charpy V-Notch (impact) and ASTM G65 (abrasion) test results, which objectively verify that the steel meets the necessary physical standards for your machinery.

When I deal with professional buyers, I actually prefer when they ask for these reports. It shows me they know what they are doing. A "Material Test Report" (MTR) is like a birth certificate for your batch of parts. It traces the steel from the furnace to the final product. If a supplier gets defensive or delays sending these when asked, that is a massive red flag.

Understanding the Key Tests

You do not need to be a metallurgist to read these reports, but you do need to know which two numbers matter the most.

1. Impact Toughness (Charpy V-Notch)

This test measures how much energy the steel can absorb before it fractures.

- The Test: A heavy pendulum swings and hits a notched sample of the steel.

- The Metric: Joules (J).

- The Standard: For a standard excavator tooth, you want to see a value of ≥ 20 Joules at room temperature. For premium mining teeth (Ni-Cr-Mo), we target ≥ 25 or 30 Joules.

- Translation: If the number is low (e.g., 10J), that tooth is brittle. It might be hard, but it will snap like a dry twig when it hits a rock. Learn more about the Charpy V-Notch 7 test.

2. Abrasion Resistance (ASTM G65)

This is the gold standard for measuring wear life.

- The Test: A sample is pressed against a rotating rubber wheel with sand flowing between them.

- The Metric: Mass Loss (usually in grams or cubic millimeters).

- The Standard: A lower number is better. It means less steel was rubbed away.

- Translation: This predicts how many hours the tooth will last in the dirt. Check the official ASTM G65 8 standard.

Internal vs. Third-Party

At Dingtai, we do internal testing on every batch (100% inspection), but for large orders or new partners, we often use SGS or other third-party labs to validate our findings.

What a Good Report Looks Like

When you receive a report, it should contain a chemical analysis and a physical properties table. Here is a simplified example of what valid data looks like:

| Test Item | Standard Required | Lab Result | Pass/Fail |

|---|---|---|---|

| Chemical: Carbon (C) | 0.28% – 0.35% | 0.31% | PASS |

| Chemical: Nickel (Ni) | ≥ 0.50% | 0.62% | PASS |

| Hardness (Surface) | 48 – 52 HRC | 50.5 HRC | PASS |

| Impact Energy (25°C) | ≥ 20 J | 24 J | PASS |

| Microstructure | Tempered Martensite | Fine Grain Level 2 | PASS |

The Importance of Microstructure

The report should also mention "Microstructure." You want to see "Tempered Martensite" or "Bainite." If you see "Ferrite" or "Pearlite" in a finished bucket tooth report, the heat treatment was done poorly. Those structures are too soft for G.E.T. applications. By verifying Tempered Martensite 9 structures, you protect your business from the hidden costs of poor quality control.

How do I track tooth wear across my fleet?

Many operators wait until a tooth falls off or wears into the adapter before taking action, which is the most expensive way to manage your undercarriage and G.E.T. inventory.

The most effective method is to establish a weekly visual inspection log where you measure the remaining length of the tooth. By tracking the rate of length loss against the hours worked, you can predict exactly when to order replacements, avoiding rush shipping costs and adapter damage.

I cannot tell you how many times I have seen a perfectly good bucket ruined because the operator let the teeth wear down too far. Once the wear reaches the adapter (the part welded to the bucket), you are looking at a repair bill that is ten times the cost of a new set of teeth. Plus, dull teeth kill your productivity.

The Hidden Cost of Dull Teeth

It is not just about the metal. A dull tooth requires more hydraulic force to penetrate the ground. This means:

- Higher Fuel Consumption: Your engine works harder for every bucket load.

- Cycle Time Increase: It takes longer to fill the bucket.

- Machine Stress: Extra strain is put on the boom, arm, and hydraulic cylinders 10.

Setting Up a Tracking System

You do not need complex software. A simple clipboard in the cab or a shared Google Sheet works wonders. The key is consistency.

Step 1: The Baseline

Measure a brand-new tooth from the locking pin hole to the tip. Let’s say it is 300mm. This is your 100% value.

Step 2: The "Red Line"

Determine your discard point. Usually, once a tooth loses 30% to 40% of its length, it has lost its penetration efficiency and is getting dangerously close to the adapter. If the new tooth is 300mm, your "Red Line" might be 180mm.

Step 3: The Routine

Every Friday, or at every 50-hour service interval, have the operator or mechanic measure the center tooth. The center teeth usually wear faster than the corner teeth.

Visual Wear Patterns

Aside from length, train your team to look for these specific wear patterns:

- Bottom Wear (Heeling): If the bottom of the tooth is wearing thin, it might indicate the operator is dragging the bucket too much or the bucket angle is wrong.

- Rounding: If the tooth looks like a fist, it is not cutting; it is smashing. This destroys fuel efficiency.

- Asymmetrical Wear: If one side wears faster, check the bucket alignment or the boom cylinders.

Sample Tracking Log

Here is a template I recommend to my dealers to pass on to their end-users:

| Machine # | Date | Hours | Tooth Length (mm) | % Worn | Notes |

|---|---|---|---|---|---|

| EX-200 | Oct 1 | 4500 | 280 | 0% | New Set Installed |

| EX-200 | Oct 15 | 4600 | 260 | 7% | Normal Wear |

| EX-200 | Nov 1 | 4700 | 230 | 18% | — |

| EX-200 | Nov 15 | 4800 | 190 | 32% | ORDER REPLACEMENT |

| EX-200 | Dec 1 | 4900 | 175 | 37% | SCHEDULE SWAP |

By using a log like this, you move from "reactive" (fixing broken things) to "proactive" (scheduled maintenance). You can order parts via sea freight instead of air freight, saving huge amounts on logistics, and you can schedule the downtime for a rainy day or a shift change, ensuring your fleet never stops earning money.

Conclusion

Choosing the right bucket teeth is not just about fitting a part; it is about engineering your fleet for profit. By selecting the correct alloy (Ni-Cr-Mo for impact, 42CrMo for general use), targeting the right hardness zones, and demanding proof of quality through test reports, you eliminate guesswork. Start tracking your wear today, and you will turn your maintenance department from a cost center into a strategic asset.

Footnotes

1. Overview of the science of metals and their chemical properties. ↩︎

2. How elemental makeup determines material properties and performance. ↩︎

3. Element data for Molybdenum, critical for steel hardening. ↩︎

4. Caterpillar’s guide to selecting and maintaining GET for machinery. ↩︎

5. Technical explanation of sudden structural failure in high-strength materials. ↩︎

6. Definition of the maximum stress a material withstands while stretching. ↩︎

7. Standardized test method for measuring material toughness and impact energy. ↩︎

8. Official standard for measuring abrasion using sand and rubber wheels. ↩︎

9. Breakdown of the ideal microstructure for high-strength steel applications. ↩︎

10. Explanation of mechanical actuators used in heavy construction machinery. ↩︎