I still remember the frantic call I received from a client in Arizona last summer; his entire fleet of dozers was grounded because the roller seals he bought from a "budget" supplier had disintegrated in the 110°F heat. It was a painful lesson in how saving a few dollars on internal components can cost thousands in downtime.

For heavy-duty mining, I recommend SKF, Timken, or FAG bearings paired with NOK or Parker seals due to their superior load ratings and heat resistance. For general construction, NSK or NTN bearings with Trelleborg seals offer the best balance of performance and cost. Always prioritize floating seals made from high-alloy cast iron to prevent mud ingress.

Choosing the right internal components is the invisible difference between a roller that lasts 2,000 hours and one that lasts 5,000 hours. Let’s dive into the specifics so you can build a Bill of Materials 1 (BOM) that protects your reputation.

Which bearing brands deliver the best performance for heavy-duty excavators?

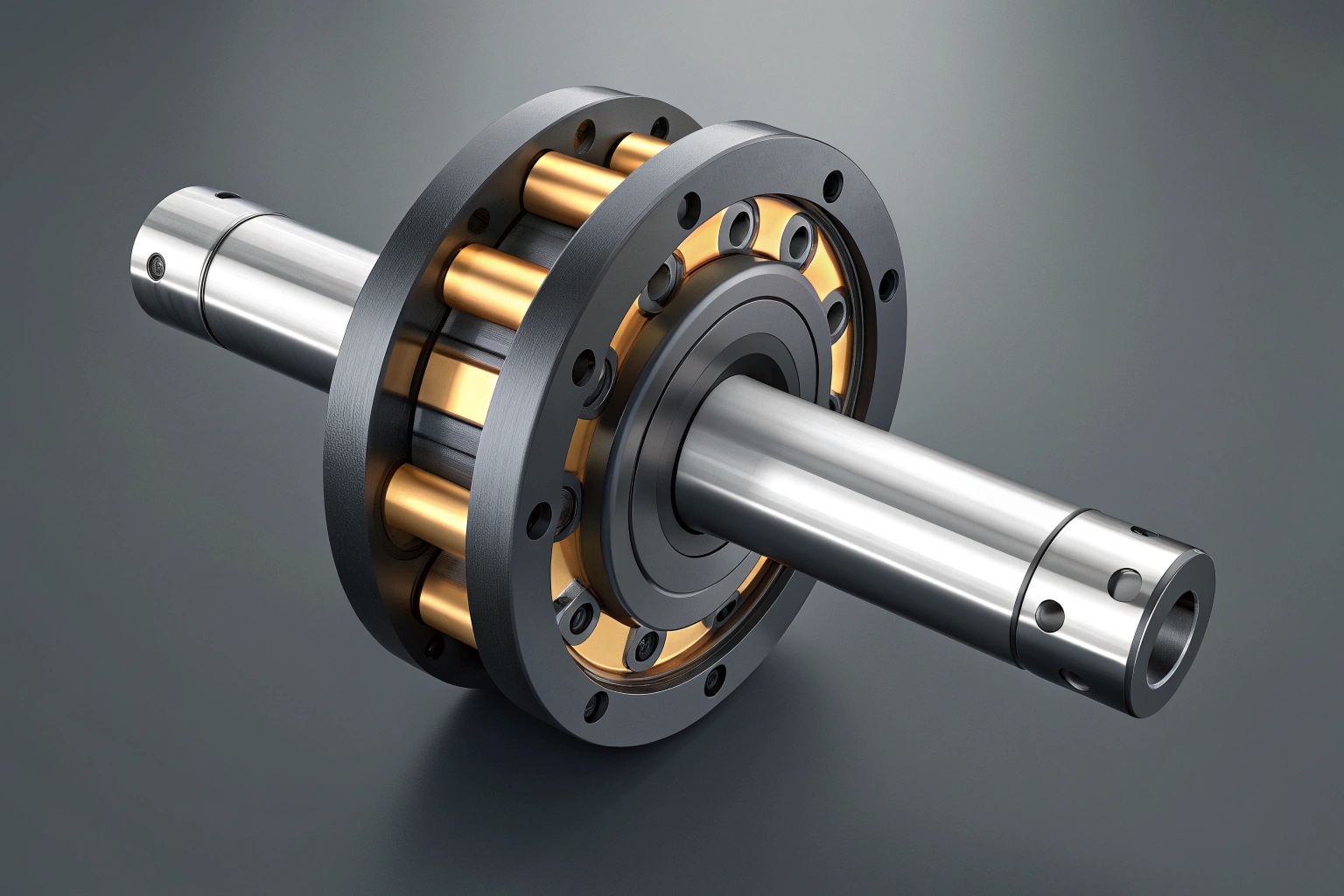

I have seen too many distributors focus solely on the external hardness of the roller shell, completely ignoring that the bearing inside is what actually carries the load. If the bearing cages fail under impact, the roller stops turning, and your track link starts grinding a flat spot on the shell within hours.

I consistently suggest SKF, Timken, and FAG for extreme impact conditions found in mining and quarrying. Their metallurgy and heat treatment processes resist spalling better than any competitors. For standard infrastructure applications, Japanese brands like NSK and NTN provide reliable precision at a significantly lower cost point.

When we analyze the failure data of undercarriage rollers, nearly 40% of premature failures are linked to bearing fatigue or collapse. This makes your choice of brand a critical engineering decision, not just a purchasing one.

The Hierarchy of Bearing Brands

To make this complex market easier to navigate, I break down the options into three distinct tiers based on the "Load Rating" (Cr) and "Static Load Rating 2" (Cor) required for different environments. This is the exact logic I use when configuring production lines for my OEM clients.

Tier 1: The Mining Champions (SKF, FAG, TIMKEN)

If your end-user is operating in a copper mine in Chile or a granite quarry in Canada, you cannot compromise.

- SKF (Sweden): Their "Explorer" series bearings use an upgraded steel that is cleaner than standard ISO steel. Fewer inclusions in the steel mean fewer starting points for fatigue cracks.

- TIMKEN (USA): They are the undisputed kings of Tapered Roller Bearings 3. Their case-carburized steel allows the surface to be hard while the core remains tough, which is crucial for absorbing the shock when a 50-ton excavator drops off a rock.

- FAG (Germany): Known for extreme precision. Their cage designs are robust, preventing the rolling elements from skewing during high-speed travel.

Tier 2: The Construction Standard (NSK, NTN, KOYO)

For 80% of the market—road building, residential construction, and utility work—these Japanese brands are the gold standard.

- They are the OEM choice for Komatsu, Hitachi, and Kobelco.

- NSK: Excellent sealing technology on sealed bearings (if applicable) and consistent geometry.

- NTN: Very strong in the construction machinery sector, offering excellent resistance to contamination.

Tier 3: The Economic Warriors (ZWZ, LYC, C&U)

Don’t underestimate the top Chinese brands.

- ZWZ and LYC: These are state-owned enterprises that supply the Chinese military and high-speed rail. For agricultural excavators or older machines where the owner is price-sensitive, these are perfectly adequate and reliable.

Technical Specifications to Watch

It is not just about the brand; it is about the spec. Even within SKF, there are different grades. You need to look for:

- Clearance: For undercarriage rollers, we typically use C3 clearance. This provides extra room for thermal expansion 4. If you use standard clearance (CN), the bearing might seize when the roller heats up during long travel distances.

- Cage Material: For heavy impact, avoid standard pressed steel cages if possible. Polyamide (Nylon) cages or Machined Brass cages (though expensive) handle vibration much better.

Comparative Analysis Table

I prepared this table to help you match the bearing brand to your customer’s specific application profile:

| Brand Tier | Top Brands | Best Use Case | Impact Resistance | Cost Index |

|---|---|---|---|---|

| Premium | SKF, Timken, FAG | Mining, Quarry, Demolition | ★★★★★ | 100% (Baseline) |

| Standard | NSK, NTN, KOYO | Road Building, Forestry | ★★★★☆ | 70-80% |

| Economy | ZWZ, LYC, C&U | Agriculture, Landscaping | ★★★☆☆ | 40-50% |

When you send me an inquiry, tell me "David, I need Tier 2 bearings." This saves us days of emailing back and forth. I can immediately calculate the cost using NSK or NTN pricing, giving you a quote that matches your market position.

Is FKM better than NBR for my operating temperatures?

I often see purchase orders requesting "Viton seals" (FKM) simply because the buyer assumes expensive means better, but this can actually lead to leaks in cold climates.

FKM (Viton) is superior for high-temperature environments exceeding 100°C or chemically aggressive sites. However, for standard construction work between -30°C and 100°C, NBR (Nitrile) offers better abrasion resistance, rebound resilience, and flexibility at a significantly lower price point.

The debate between FKM and NBR is one of the most misunderstood topics in our industry. The "seal" in a floating seal 5 assembly consists of two parts: the metal ring (which does the sealing) and the rubber O-ring (which provides the tension). When we discuss material, we are talking about that rubber O-ring (Toric Ring).

The Science of "Compression Set"

The most critical property for a roller seal is Compression Set 6. This measures the rubber’s ability to return to its original shape after being squeezed.

- The rubber ring is compressed when installed. This compression creates the spring force that pushes the two metal faces together.

- If the rubber loses its elasticity (takes a "set"), the pressure on the metal faces drops.

- Once the pressure drops, oil leaks out, and dirt gets in.

- NBR Advantage: High-quality NBR generally has better rebound resilience (lower compression set) than standard FKM, especially in dynamic applications where the roller is vibrating constantly.

Temperature: The Deciding Factor

- The NBR Sweet Spot (-30°C to +100°C): For most of the world, NBR is perfect. It remains snappy and flexible. In freezing conditions (like a winter in Minnesota or Northern Europe), NBR stays elastic. FKM tends to harden and become glass-like at temperatures below -20°C, which can cause immediate leakage upon startup on a cold morning.

- The FKM Necessity (>100°C): If your machines are working in steel mills, asphalt paving (near hot mix), or deep desert mining where friction heat builds up, NBR will bake. It becomes hard and cracks. Here, FKM is mandatory as it survives up to 200°C.

Chemical Resistance

Another angle to consider is the soil environment.

- NBR: Vulnerable to ozone and certain strong acids. If the machine is stored outside in direct sunlight for years (inventory), NBR can degrade faster due to UV/Ozone exposure (though inside a roller, it is protected).

- FKM: Impervious to almost all chemicals. If the excavator works in a chemical plant cleanup or acidic mine drainage, FKM provides a safety layer that NBR cannot.

Cost vs. Benefit Analysis

FKM seals typically cost 3 to 5 times more than NBR seals.

- If you specify FKM for a standard construction roller, you are adding cost without adding value.

- Worse, you might be reducing reliability if the machine operates in cold weather.

My Recommendation: Unless you have a specific requirement for high heat or chemical resistance, stick to a High-Acrylonitrile NBR. "High ACN" NBR offers better oil resistance and toughness than standard NBR, bridging the gap without the high cost of FKM.

How do seal lip designs and brands affect mud ingress?

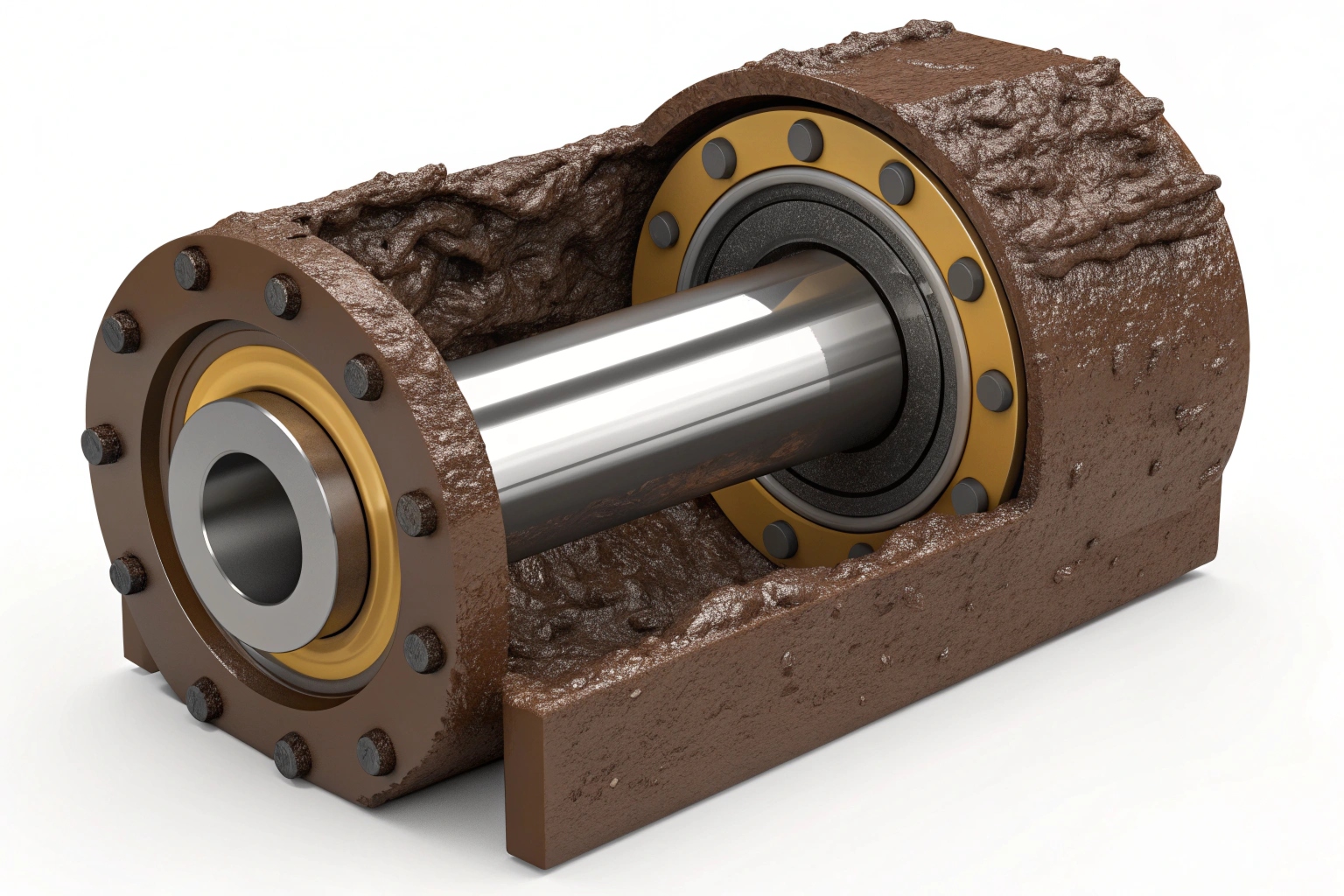

Mud is relentless; I have seen it work its way past inferior seals in less than 50 hours of operation, turning the oil into a grinding paste that destroys the shaft.

Premium brands like NOK and Freudenberg utilize advanced lip geometries and precise lapping technology that maintain a perfect oil film even when the roller shifts under load. I find that generic seals often lack the critical "light band" flatness required to keep fine slurry out of the oil cavity.

The "lip" of a floating seal is not rubber; it is a precision-ground band on the metal face. The technology here is microscopic, yet it determines the macro performance of the entire machine.

The Physics of the "Floating" Seal

The two metal rings rotate against each other. They are held together by the rubber rings we discussed earlier. The "lip" or sealing band is a tapered section on the face.

- The Wedge Shape: As the roller spins, the gap between the rings is designed to draw oil outward by centrifugal force 7 to lubricate the face, while preventing dirt from moving inward.

- Light Band Flatness: The flatness of these metal rings is measured in "Helium Light Bands." A top-tier seal (NOK/CAT) is lapped to a flatness of within 2 light bands (approx 0.00002 inches). Cheap seals might be 4-6 light bands. If it’s not flat, it leaks.

Brand-Specific Design Philosophies

1. NOK / Freudenberg (The Industry Leader)

- Design: They use a specific "spherical" profile on the metal face. As the seal wears down, the contact band moves but the pressure remains constant.

- Material: They use Ni-Hard Cast Iron (Nickel-Chromium). This material has a hardness of HRC 65+. Even if silica sand gets caught in the seal, the seal is harder than the sand, crushing the grit rather than being scored by it.

2. Trelleborg (The European Giant)

- Design: Known for their "DO" style seals. They have excellent elastomer (rubber) consistency. Their design focuses on stability—preventing the seal from spinning in the housing (which is a catastrophic failure mode).

3. The Risk of Generic Brands

- In the aftermarket, many factories produce "copy" seals. Visually, they look identical.

- The Problem: They often use standard Bearing Steel 8 (GCr15) instead of High-Alloy Cast Iron. Bearing steel is hard, but it lacks the corrosion resistance and the specific microstructure needed for a face seal. They rust quickly when the machine sits idle, destroying the smooth face.

The Impact of "Mud Packing"

In deep mud, the external pressure on the seal increases.

- Poor Design: The mud packs into the gap, pushing the rubber ring out of position. The seal face opens, and mud pours in.

- Premium Design (e.g., CAT Duo-Cone): The housing and seal geometry form a labyrinth. The shape creates a natural "flinger" effect that throws mud away from the sealing interface.

Seal Selection Matrix

| Application Scenario | Recommended Brand | Seal Material | Key Feature Needed |

|---|---|---|---|

| Swamp / Wet Clay | NOK, CAT, Parker | Ni-Hard Cast Iron | High external pressure resistance |

| Dry / Sandy | Trelleborg, Hallite | High-Chrome Iron | Abrasion resistance |

| General Digging | Quality Chinese (Dinghu) | 100Cr6 / GCr15 | Cost efficiency |

When we design a custom roller for you, we look at the "Gap Clearance" (A-Dimension). We ensure that even when the roller bushing wears and the shaft tilts, the seal faces maintain 100% contact. This is the engineering detail that cheap suppliers miss.

Can I specify SKF/NSK bearings in my BOM?

You absolutely can, and for many of my premium distributors, this is a standard requirement, but you must navigate the risks of counterfeits and long lead times.

Yes, you can specify these brands, but it increases lead time and cost. I advise pairing premium bearings with a minimum 4,000-hour warranty. Demand Certificate of Origin documentation to ensure you are not receiving counterfeit products.

Specifying a BOM is a negotiation. You are balancing marketing power ("Powered by SKF") against supply chain reality.

The "Fake Bearing" Epidemic

I must be honest with you about the manufacturing landscape in China. If a supplier offers you a roller with "SKF Bearings" for only $5 more than a standard roller, they are lying.

- Genuine SKF or Timken bearings in China carry a premium due to import taxes and brand positioning.

- There are entire villages dedicated to refurbishing old bearings or printing fake packaging for generic bearings.

- Your Protection: When you order from Dingtai, we purchase directly from the authorized distributor. We provide the unique QR code on the box that you can scan with the manufacturer’s app to verify authenticity.

Managing Lead Times

Imported bearings are not always stocked in the sizes needed for specific rollers (especially older or unique excavator models).

- Domestic Bearings: Lead time is 3-5 days.

- Imported Bearings (SKF/NSK): If not in stock, lead time can be 6-8 weeks coming from Europe or Japan.

- Strategy: If you plan to use SKF, we need a rolling forecast. You cannot order "Just-in-Time" unless we hold stock for you.

The Strategic Compromise: Hybrid BOM

For clients who want the performance of a premium roller without the price of SKF, I recommend this hybrid approach:

- The Weakest Link First: The seal fails first. Always upgrade the seal to NOK or Trelleborg. This costs maybe $2-$5 extra per roller but doubles the lifespan.

- The Bearing: Use a top-tier Chinese bearing (Tier 1 like ZWZ).

- Why: A ZWZ bearing in a clean oil bath (protected by a NOK seal) will outlast an SKF bearing in a leaking oil bath (failed cheap seal).

- Result: You get a roller that we can warranty for 3,500+ hours, but your cost remains competitive against other aftermarket parts.

Sample Approval Process (PPAP)

If you decide to specify SKF/NSK, do not just put it on the PO. Make it part of the quality protocol:

- Step 1: We send you a photo of the unboxed bearings with batch numbers before assembly.

- Step 2: We assemble a pilot batch.

- Step 3: You (or your third-party inspector like SGS 9) select one roller at random to cut open and verify the internal components match the BOM.

This level of transparency scares away the bad suppliers, but for a partner like Dingtai, it is just standard procedure to build trust.

Conclusion

The "best" brand is not always the most expensive one; it is the one that fits your customer’s reality. For mining giants, SKF/Timken bearings with NOK seals are non-negotiable insurance policies. For the vast majority of the construction market, NSK bearings with Trelleborg seals—or even our Hybrid ZWZ/NOK combination—will provide the best ROI.

What I can do for you next

Would you like me to prepare a "Good, Better, Best" quotation for your top 5 selling roller part numbers? I can breakdown the exact cost difference between using Chinese components, Japanese components, and European components so you can decide which tier fits your market strategy. You should also check the Certificate of Origin 10 to verify your components.

Footnotes

1. Definition of a Bill of Materials in manufacturing planning. ↩︎

2. How static load ratings determine bearing capacity. ↩︎

3. Overview of tapered roller bearing advantages for heavy loads. ↩︎

4. Physics of thermal expansion in metal components. ↩︎

5. Solutions for mechanical face seals in heavy duty machines. ↩︎

6. Why compression set matters for long-term sealing. ↩︎

7. Scientific explanation of centrifugal force in rotating bodies. ↩︎

8. Comparison of common steel materials used in bearings. ↩︎

9. Role of SGS in third-party industrial verification. ↩︎

10. Importance of Certificates of Origin in global trade. ↩︎