Quenching and tempering 1, induction hardening 2, and carburizing 3 are the primary heat treatment methods applicable to excavator undercarriage parts. I find these methods beneficial as they enhance strength, wear resistance 4, and durability under heavy-duty conditions.

Quenching and tempering effectively balance strength, hardness, and toughness for various components. Induction hardening is ideal for creating localized hardened surfaces, while carburizing provides wear resistance and impact toughness for selected parts.

These methods are essential for ensuring the reliability and longevity of excavator undercarriage components, which operate under extreme stress and abrasion 5.

What induction hardening depth should my sprocket teeth have?

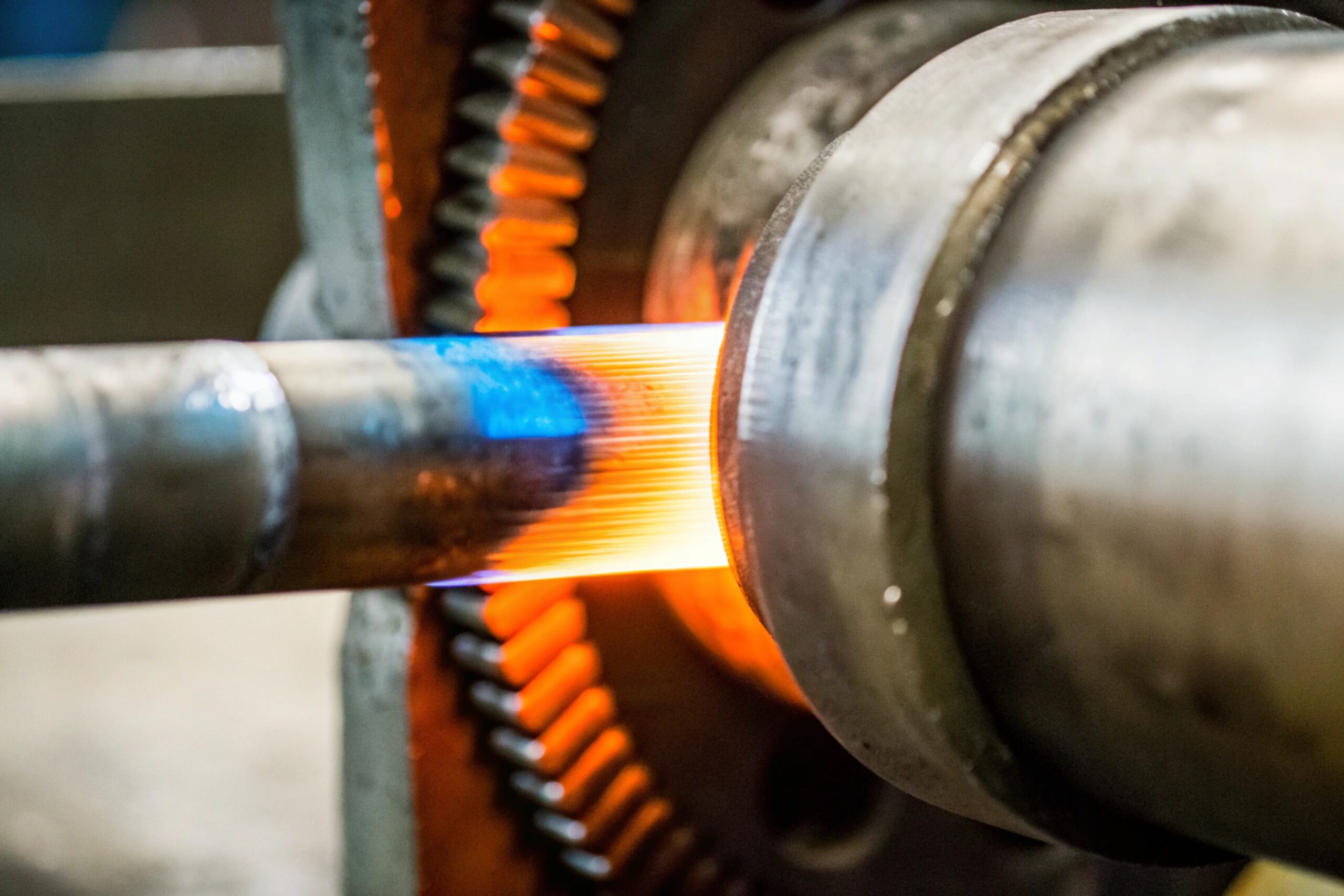

Induction hardening, with its rapid surface hardening technique 6, piqued my interest for sprocket teeth. Using PAS strategy, it ensures efficiency and enhanced surface durability with minimal deformation.

The optimal induction hardening depth for sprocket teeth is typically between 2 to 4 millimeters. This depth provides sufficient surface hardness to withstand abrasion while retaining core toughness for impact resistance.

Understanding induction hardening is essential for anyone delving into surface treatment processes 7. When considering sprocket teeth, depth and temperature settings play a crucial role. Starting with the induction principle, it relies on electromagnetic fields 8 to quickly heat and subsequently harden surface layers. Typically, the required hardening depth depends on operational demands. For instance, industries prioritizing surface wear resistance select deeper hardening, ensuring optimal performance over extended periods.

Heat Treatment Parameters

Several factors influence the outcome of induction hardening:

| Parameter | Description |

|---|---|

| Frequency | Determines skin depth; 9 higher frequencies yield shallower depths. |

| Duration | Exposure time affects the depth and uniformity of hardening. |

| Cooling Technique | Rapid cooling solidifies surface hardness, preventing deformation. |

When opting for induction hardening, it’s vital to calibrate these aspects meticulously. Altering any parameter impacts the longevity and effectiveness of the treatment. For sprocket teeth, maintaining the right balance ensures resilience against wear and tear 10. Lastly, collaborating with skilled technicians enhances precision, meeting exact specifications and achieving outstanding results.

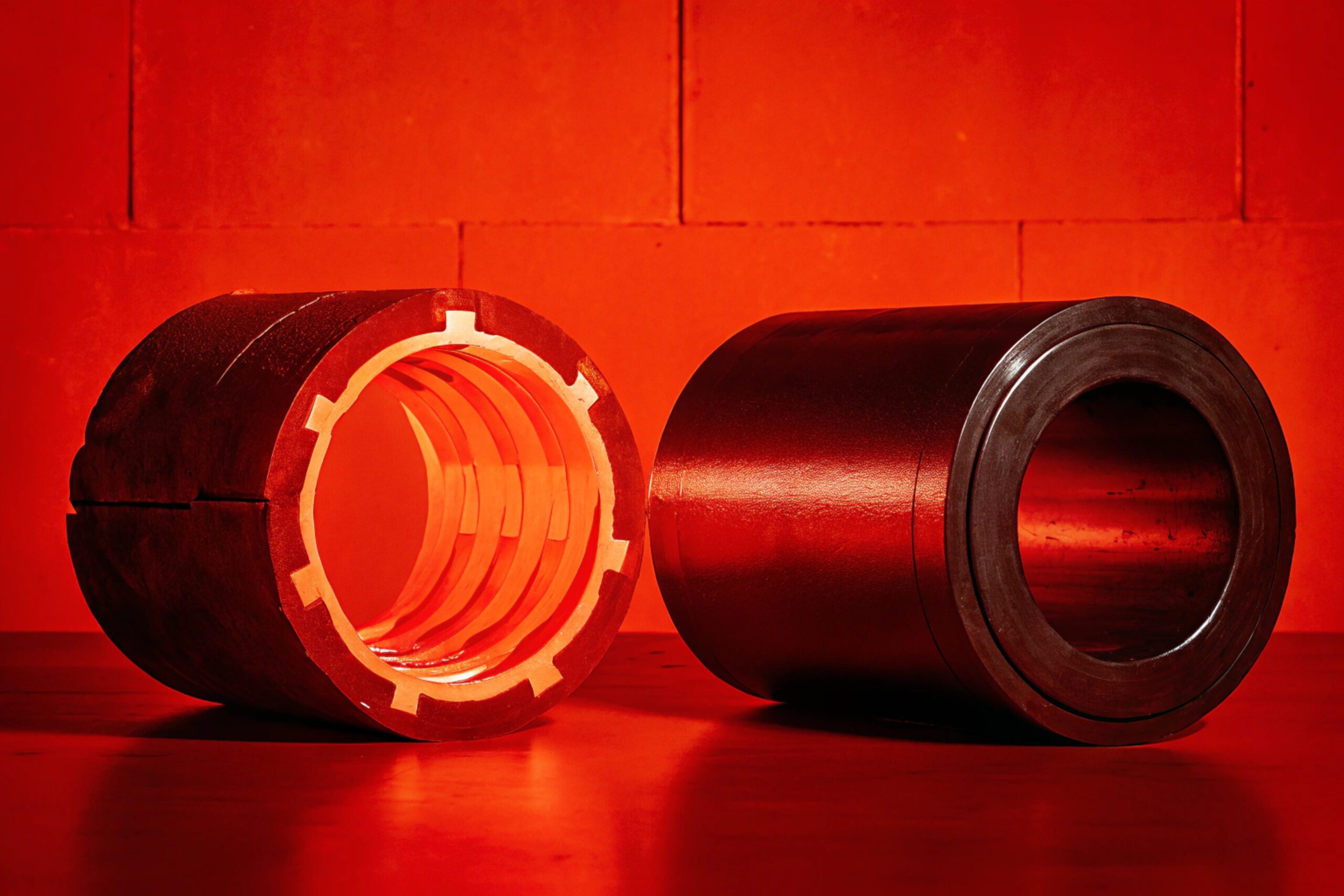

Should my bushings be carburized for wear resistance?

Amid robust operations, bushing wear intrigued me. Carburizing can significantly boost wear resistance and longevity, but it’s critical to assess if it’s the optimal solution.

Bushings should indeed be carburized for enhanced wear resistance. This process forms a hard outer layer while maintaining a tough core, making bushings more resilient to continuous friction and wear.

Carburizing introduces carbon into the surface layer, elevating wear resistance for components constantly exposed to friction. Let’s dissect why this method suits bushings:

Advantages of Carburizing

-

Surface Hardness: Carburizing markedly boosts surface hardness, reducing wear over prolonged use.

-

Core Toughness: Retains the core’s ductility, ensuring that bushings withstand rigorous operational pressures.

-

Longevity: Enhances component lifespan, reducing maintenance frequency and downtime.

Carburizing vs Other Methods

| Method | Pros | Cons |

|---|---|---|

| Carburizing | Deep surface hardness | Longer processing time |

| Nitriding | Corrosion resistance | Limited depth of hardening |

| Quench & Temper | Improved strength | Potential for distortion if not done correctly |

In summary, opting for carburizing ensures bushings achieve optimal performance and durability. Discussing requirements with technical experts offers insights, refining the treatment to meet precise demands.

How do I read tempering curves on a heat-treatment report?

Tempering curves on reports initially seemed complex. Understanding them is pivotal for evaluating component strength and toughness after heat treatment.

Tempering curves illustrate changes in hardness and toughness relative to tempering temperature and duration. By examining these curves, one can assess the material properties to ensure optimal stress resistance.

Diving into tempering curves involves recognizing key axes: hardness versus temperature. Here’s how to interpret them:

Components of Tempering Curves

-

Axes Representation: Vertical axis shows hardness ratings, while horizontal axis denotes temperature ranges.

-

Peak and Plateaus: Peaks indicate maximum hardness achievable at specific temperatures, whereas plateaus reveal stability in material properties before decline.

-

Rate of Change: The slope elucidates the rate at which hardness attenuates with rising temperature.

Practical Implications

Understanding tempering curves aids in setting precise heat treatment protocols, ensuring consistency and reliability in components such as pins, bushings, and rollers.

| Temperature Range | Expected Hardness | Application Implication |

|---|---|---|

| 200-350°C | Highest | Maximum stress resistance |

| 400-600°C | Moderate | Enhanced ductility for shock absorption |

| Above 600°C | Reduced | Limited applications due to lowered strength |

Careful analysis of these curves informs on suitable operational conditions and helps refine tempering processes. Seeking collaborative insights from material scientists can enhance the accuracy of curve interpretations.

Can I request case depth certification on pins?

Requesting certifications brings assurance. For pins, case depth certification verifies the hardening process applied, ensuring guaranteed performance.

Yes, you can request case depth certification on pins. This certification confirms the treatment depth, ensuring that pins meet specified surface hardness and core ductility standards.

The essence of case depth certification lies in guaranteeing precise treatment depth, vital for pins frequently exposed to cyclical loads. Here’s what to consider:

Certification Elements

-

Depth Measurement: Verifies the exact hardening depth achieved, confirming the pin’s operational reliability under stress.

-

Material Properties: Assessed for consistency, offering valuable insights into potential applications and longevity.

-

Verification Techniques: Involving sophisticated testing methodologies ensures accurate measurement of hardening depth.

Certification Request Guidelines

| Certification Aspect | Description |

|---|---|

| Request Procedure | Initiate request through manufacturer or third-party testing facilities. |

| Parameters Set | Specify exact treatment depth required based on intended application. |

| Validation | Employ certified labs for thorough testing, ensuring unbiased results. |

Requesting case depth certification fortifies trust in component capability, enabling confidence in operational settings. Regular reviews of certification standards promote awareness, ensuring pins deliver optimal functionality across diverse applications.

Conclusion

Heat treatment techniques like quenching, induction hardening, and carburizing optimize excavator parts, ensuring performance and durability.

Footnotes

1. Learn about quenching and tempering to balance material hardness and toughness. ↩︎

2. Guide to induction hardening for localized surface strengthening. ↩︎

3. Explanation of the carburizing process for creating a hard outer case. ↩︎

4. Insights on materials and methods for improving wear resistance. ↩︎

5. Analysis of how stress and abrasion impact material degradation. ↩︎

6. Comparison of common surface hardening techniques in metallurgy. ↩︎

7. Overview of industrial surface treatment processes for metals. ↩︎

8. The role of electromagnetic fields in the induction heating process. ↩︎

9. Defining skin depth (or effect) in induction hardening applications. ↩︎

10. Methods for improving resilience against wear and tear in machinery. ↩︎