Choosing the right steel grade for excavator undercarriage parts is crucial. I need to ensure that my components are durable and fit for various loads and conditions.

To meet diverse operational demands, it’s essential to select the appropriate steel grades for undercarriage parts. 40Mn2, 35MnB, and 42CrMo steels each offer unique benefits suited to different applications. 40Mn2 is favored for heavy-load parts, 35MnB for components facing impact, and 42CrMo for high-strength parts requiring fatigue resistance.

Understanding the differences among steel grades allows me to customize solutions for specific operating needs and improve parts’ lifespan.

What trade-offs exist between impact toughness and hardness?

The choice between impact toughness and hardness isn’t simple. Each offers benefits in different conditions, and I often weigh these factors carefully to ensure optimal performance.

Impact toughness enhances the durability of parts against sudden shocks, while hardness offers superior wear resistance. However, these properties are often at odds; higher hardness can lessen toughness. Selecting the right balance depends on the part’s specific function and exposure to wear and impact.

To dive deeper into this subject, let’s examine how different steel grades address these trade-offs. For instance, 40Mn2 steel finds a middle ground by offering both moderate hardness and toughness, making it suitable for components like track rollers and idlers 1. This balance allows it to handle pressure and wear without cracking.

In contrast, 35MnB emphasizes hardness and is often used for track links exposed to abrasive environments. The boron content in 35MnB steel 2 increases surface hardness, reducing wear even with repeated use. However, this comes with less impact toughness than 40Mn2.

For critical components, 42CrMo excels in high-stress areas due to its superior fatigue resistance 3, being both hard and tough after treatment. It’s ideal for shafts that undergo cyclic loads, though its higher cost requires cautious application in terms of budget constraints.

Steel Grade Properties Comparison

| Steel Grade | Impact Toughness | Hardness Range (HRC) | Typical Applications |

|---|---|---|---|

| 40Mn2 | Moderate | 36-60 | Track rollers, idlers, sprockets |

| 35MnB | Lower | 48-56 | Track links, cutting edges |

| 42CrMo | High | 50-60 | Shafts, heavily stressed components |

Do I need boron-treated steel for heavy mining duty?

Mining presents severe job conditions. In these cases, sensitivity to the material properties is crucial for efficiency and safety.

For tasks subjected to continuous abrasive forces, boron-treated steel such as 35MnB is highly beneficial. It delivers improved hardness, crucial for withstanding the rigorous challenges faced during heavy mining duty. Applying boron-treated steel can prolong parts’ life by minimizing wear and fracture, particularly in conditions requiring tremendous impact resilience.

Diving into the specifics reveals why this choice matters. Boron-treated steel like 35MnB enhances a component’s surface hardness by creating a robust wear-resistant layer 4. This layer is particularly effective in environments where parts contact rough surfaces repeatedly, such as mining fields.

Additionally, the steel’s hot rolling properties 5 allow it to reshape progressively under stress, aiding in its durability. Tracks, links, or joints exposed to severe abrasion greatly benefit from this attribute, as they encounter less friction degradation.

However, relying exclusively on 35MnB without considering the necessary toughness equalizes the potential downfall. In mining, the balance between toughness and hardness determines part longevity. Parts like excavator teeth may also need alloy additives 6 to counter brittleness created by excessive hardness.

Given these considerations, choices between boron-treated and conventional steel should derive from operational demand assessments. This foresight in defining need-specific applications can translate to prolonged functionality and effective cost management.

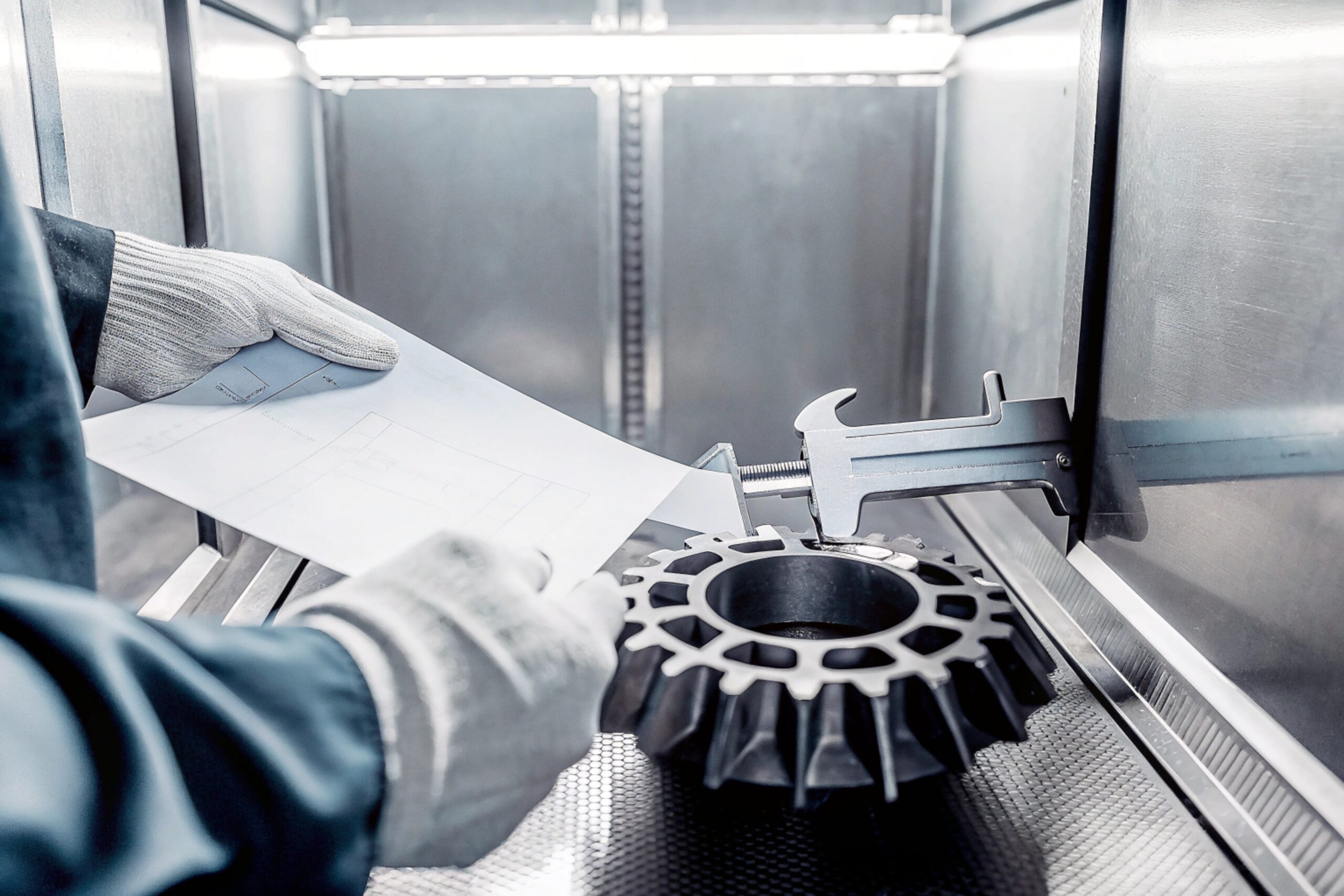

How do I verify heat numbers against my MTC?

Verifying heat numbers is a step I can’t overlook. It ensures I have the right material and prevents serious operational hiccups.

To confirm material compliance, I cross-reference heat numbers from the material test certificate (MTC) against my stock labels. This process guarantees alignment with metallurgy specifications, validating integrity before deployment. Consistency checks protect against possible material mismatches or inaccuracies during manufacturing sequencing and post-purchase periods.

Let’s unravel the procedure ensuring precision and compliance. Heat numbers, a traceability measure, link materials to specific production batches through their MTCs. This link facilitates catalog tracking, leading from issuance to component usage.

Here’s the typical verification process:

-

Acquire MTC: Consult certificates accompanying deliveries. They list relevant data, including chemical composition, mechanical properties, and heat numbers.

-

Cross-Referencing: Compare the heat numbers printed on delivery sheets or labels directly to those in the material test certificate (MTC) 7.

-

Documentation Checks: Use software designed for traceability systems 8 to compete verification tasks. This system records matches or mismatches, preventing manual error.

-

Review of Properties: Should discrepancies arise, re-examine material properties. Ensuring they meet design and operational specifications is imperative.

-

Audit Trails: Facilitate accountability by logging verified batches and providing serialized tracking back to equipment installation documents.

Thorough validation grants confidence in material reliability. Knowledge that components meet prescribed properties enhances operational assurance—a necessary stepping stone before exposure to excavator duties.

Verification Checklist

| Step | Activity | Purpose |

|---|---|---|

| Acquire MTC | Obtain accurate documentation | Confirm original manufacturing data |

| Cross-Referencing | Compare heat numbers with MTC | Validate material against specs |

| Documentation Checks | Software validations | Enhance traceability and minimize human error |

Can I specify alternate grades for cold climates?

Function in cold climates calls for adaptability. Each weather demand drives modification necessity to ensure reliability.

Specifying alternate steel grades like 42CrMo for cold climates enhances structural endurance. The grade’s excellent low-temperature toughness withstands frigid conditions, ensuring operational stability. Ensuring steel grade compatibility allows equipment to thrive even under extreme cold without failing or damaging integrity.

Here’s what to keep in mind when considering alternate grades. Cold climates require steels resistant to brittleness that occurs due to temperature drops. 42CrMo’s robustness and low-temperature toughness 9 make it suitable for such environments. This property helps avoid fractures when undercarriage components face sudden impacts or sustained stresses at low temperatures.

Additionally, modifications in the heat treatment process, like tempering or annealing 10, may bolster alternate steel grades, easing strain during cold climate operation.

Design flexibility dovetails into other factors; alloy selection can play a role. Incorporating nickel or chromium into the steel composition enhances fracture resistance amidst freezing, ensuring cohesion across cross-section areas, especially in welds.

Building upon tailored strategies, specifying steel materials responsive to cold environments without impairing durability offers resilience. Ultimately, aligning practical solutions with climatic challenges advances stability.

Cold Climate Adaptation Chart

| Steel Grade | Temperature Range | Adaptation Highlights |

|---|---|---|

| 42CrMo | -20°C to -40°C | Superior toughness, ideal for shafts |

| 40Mn2 | -10°C to -30°C | Resilient wear resistance |

| 35MnB | -10°C to -25°C | Moderate hardness and ductility |

Conclusion

By understanding different steel grades, I specify options tailored to specific undercarriage needs, maximizing operational efficiencies across varied conditions.

Footnotes

1. Defines the function of track rollers and idlers in an excavator. ↩︎

2. Explains how boron additives increase steel hardness. ↩︎

3. A guide to understanding metal fatigue and resistance. ↩︎

4. Details methods for applying wear-resistant coatings to steel. ↩︎

5. Learn about the steel hot rolling process and its effects. ↩︎

6. Overview of common alloying elements and their purpose. ↩︎

7. Understand the purpose and contents of an MTC. ↩︎

8. How traceability systems work in industrial manufacturing. ↩︎

9. Learn why toughness is critical for steel in cold environments. ↩︎

10. Compares the two main heat treatment processes. ↩︎